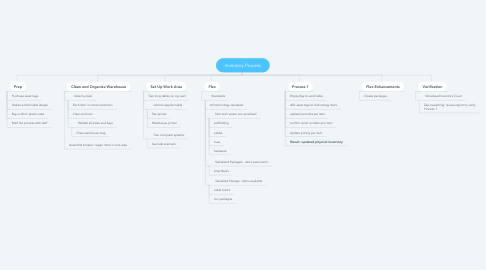

Inventory Process

by Lee Dickinson

1. Clean and Organize Warehouse

1.1. Aisle by Aisle

1.1.1. Each item in correct positions

1.1.2. Clean and sort

1.1.3. Relabel all aisles and bays

1.1.3.1. Draw warehouse map

1.2. Assemble broken / repair items in one area

2. Verification

2.1. Scheduled Inventory Count

2.1.1. Zap everything, review report to verify Process 1

3. Flex Enhancements

3.1. Create packages

4. Flex

4.1. Standards:

4.1.1. All technology serialized

4.1.2. Non-tech assets non-serialized

4.1.2.1. scaffolding

4.1.2.2. cables

4.1.2.3. truss

4.1.2.4. hardware

4.1.3. Serlialized Packages - items permanent

4.1.3.1. Amp Racks

4.1.4. Serialized Storage - items available

4.1.4.1. cable trunks

4.1.4.2. mic packages

5. Set Up Work Area

5.1. Two long tables on cyc wall

5.2. central supplies table

5.2.1. flex printer

5.2.2. Warehouse printer

5.3. Two computer systems

5.3.1. barcode scanners