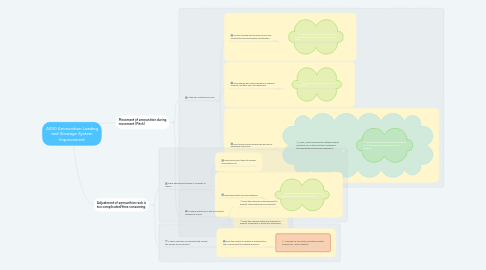

1. Movement of ammunition during movement (Pitch)

1.1. Is the Rail material non-slip?

1.1.1. Is their enough surface area of non-slip material to hold ammunition effectively?

1.1.1.1. Would it benefit from an extra rail in the centre providing more stability and extra grip?

1.1.2. Have there been improvements in material science i.e better non-slip materials?

1.1.2.1. Would it benefit from new non-slip material?

1.1.3. Did it used to work effectively and has it degraded over time?

1.1.3.1. If yes, How long does the material remain effective for? is this an action featured in the maintenance/servicing schedules?

1.1.3.1.1. Update maintenance/servicing schedules to include periodic replacement of rail material.

1.2. In which directions is the ammunition allowed to travel?

1.2.1. Does this require full encasement to prevent omni-directional movement?

1.2.2. Does this require partial encasement to prevent movement in particular directions?

2. Adjustment of ammunition rack is too complicated/time consuming.

2.1. What adjustment system is currently in place?

2.1.1. How long does it take to change ammunition fit?

2.1.2. What specialist tools are required?

2.1.2.1. Can a self-locking adjustable system be integrated into the stowage device?

2.2. Is there unknown constraints that forced the design to be like this?

2.2.1. Does the centre of gravity or alignment of the round effect the loading process?

2.2.1.1. Moving to a one point adjustable system effects this, does it matter?