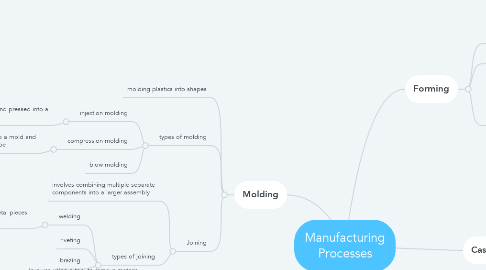

1. Molding

1.1. molding plastics into shapes

1.2. types of molding

1.2.1. injection molding

1.2.1.1. hot plastic is heated and pressed into a mold

1.2.2. compression molding

1.2.2.1. material is placed into a mold and compressed into shape

1.2.3. blow molding

1.3. Joining

1.3.1. involves combining multiple separate components into a larger assembly

1.3.2. types of joining

1.3.2.1. welding

1.3.2.1.1. using high heat to melt two metal pieces together

1.3.2.2. riveting

1.3.2.3. brazing

1.3.2.4. soldering

1.3.2.5. fastening

2. Machining

2.1. involves using a tool to remove material from a larger object. wide material range

2.2. types of machining

2.2.1. drilling

2.2.1.1. drilling a circular hole with a drill bit

2.2.2. turning

2.2.2.1. using a cutting tool to cut into a rotating object

2.2.3. reaming

3. Manufacturing process selection

3.1. required levels of automation

3.2. number of parts

3.3. material

3.4. object geometry

3.5. tool and material costs

4. Additive

4.1. involves adding material to build up an object, typically one layer at a time

4.2. types of additive

4.2.1. 3d printing

4.2.1.1. a computer is used to successfully build up an object layer by layer. Process is slow and unfit for mass production.

4.2.2. selective laser sintering

4.2.3. vat polymerization

5. Forming

5.1. involves applying forces or pressure and plastically deforming the material to produce the desired shape

5.2. hot working vs cold working

5.3. types of forming

5.3.1. rolling

5.3.1.1. involves pouring molten metal into a mold and allowing it to solidify

5.3.1.2. passing hot sheets of metal through rollers to give them shape

5.3.2. forging

5.3.2.1. hammering hot metal into given shapes

5.3.3. extrusion

5.3.3.1. straining hot metal through a shaped opening

6. Casting

6.1. types of casting

6.1.1. sand casting

6.1.1.1. molten metal is injected into a sand mold.

6.1.2. die casting

6.1.2.1. molten metal is injected into a metal mold. mostly used for non-ferrous metals.

6.1.3. investment casting

6.1.3.1. a ceramic mold is made from a wax object. molten metal is injected into the mold