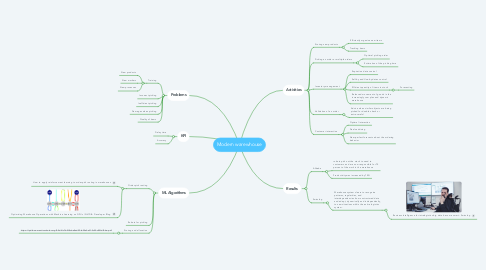

1. Problems

1.1. Training

1.1.1. New products

1.1.2. New workers

1.1.3. New processes

1.2. Incorrect picking

1.3. Inefficient picking

1.4. Damages when picking

1.5. Quality of items

2. KPI

2.1. Delay time

2.2. Accuracy

3. ML Algorithms

3.1. Order-pick routing

3.1.1. How to apply reinforcement learning to order-pick routing in warehouses

3.1.2. Optimizing Warehouse Operations with Machine Learning on GPUs | NVIDIA Developer Blog

3.2. Robots for picking

3.3. Storing and allocation

3.3.1. https://pdfs.semanticscholar.org/50d4/c7b0f8cbe8ed59fa20e3a315c02c80fdf3be.pdf

4. Activities

4.1. Storing new products

4.1.1. Efficiently organize new items

4.1.2. Tracking items

4.2. Picking an order or multiple orders

4.2.1. Optimal picking order

4.2.2. Estimation of the picking time

4.3. Inventory management

4.3.1. Expiration date control

4.3.2. Sell-by and Use-by dates control

4.3.3. Efficient quantity of items in stock

4.3.3.1. Forecasting

4.3.4. Balanced movement of goods in the increasingly complex and dynamic warehouse

4.4. Validation of an order

4.4.1. Advice when similar objects are being picked for double-check or extra-careful

4.5. Customer interaction

4.5.1. Optimal interaction

4.5.2. Deals advising

4.5.3. Near-perfect forecasts about the ordering behavior

5. Results

5.1. Alibaba

5.1.1. robots pick out the stock to send to customers and are now responsible for 70 percent of the work in the warehouse

5.1.2. Productivity was increased by 70%

5.2. Swisslog

5.2.1. Warehouse systems learn to recognize patterns, regularities, and interdependencies from unstructured data and adapt, dynamically and independently, to new situations within the entire logistics system.

5.2.1.1. Business Intelligence for intralogistics big data become smart - Swisslog