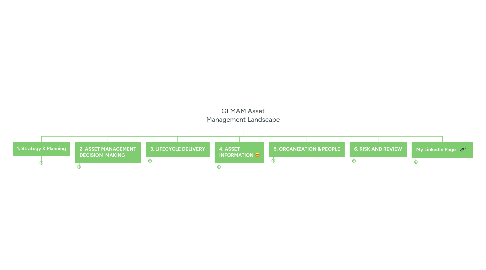

1. 1. Strategy & Planning

1.1. 1.1 Asset Management Policy

1.2. 1.2 Asset Management Strategy and Objectives

1.3. 1.3 Demand Analysis

1.4. 1.4 Strategic Planning

1.4.1. Strategic planning process

1.4.2. Strategic pitfalls and culture

1.4.3. Components of strategic plan

1.4.4. Planning tools

1.4.5. Demand Analysis

1.4.6. Establishing Priorities

1.4.7. Control and monitoring

1.5. 1.5 Asset Management Planning

1.5.1. Asset Management Policy and Strategy

1.5.2. Asset register Master Data

1.5.3. Asset condition assesment

1.5.4. Asset prioritization/ criticality

1.5.5. Lifecycle plan

1.5.6. Short term planning

1.5.7. Long range planning

1.5.8. Work order management

1.5.9. Critical support resources

1.5.10. Asset management plan

2. 2. ASSET MANAGEMENT DECISION MAKING

2.1. 2.1 Capital Investment Decision-Making

2.1.1. Elements of cost engineering

2.1.2. Engineering apprach

2.1.2.1. Life cycle costs

2.1.2.2. Weibull analysis

2.1.3. Type of capex studies

2.1.3.1. Expansion

2.1.3.2. Optimization

2.1.3.3. Financial

2.1.3.4. R&D

2.1.4. Project charecteristics

2.1.4.1. Sunken cost

2.1.4.2. Cost sharing

2.1.4.3. Lifespan

2.1.4.4. Savings

2.1.4.5. Trade-offs

2.1.5. Types of expenses

2.1.5.1. Pre-delivery costs

2.1.5.2. Fixed capital

2.1.5.3. Working capital

2.1.5.4. Operational expenses

2.1.5.5. Balance sheet expenses

2.1.5.5.1. Ammortization

2.1.5.5.2. Depreciation methods

2.1.5.6. Opportunity expenses

2.1.5.7. Salvage

2.1.6. Evaluation methods

2.1.6.1. Buyback period method

2.1.6.2. Net Present Value evaluation

2.1.6.3. Internal rate of return evaluation

2.1.6.4. Return on Investemtn evaluation

2.1.6.5. Evaluation method weaknesses

2.2. 2.2 Operations & Maintenance Decision-Making

2.2.1. Production management

2.2.1.1. Break-even analysis

2.2.1.1.1. PQTF constraints

2.2.1.2. Capacity

2.2.1.2.1. Capacity planning and control

2.2.1.2.2. Capacity adjustment strategy

2.2.1.2.3. Economies of Scale

2.2.1.2.4. Theory of constrain

2.2.1.3. Operations competitive factors

2.2.1.3.1. Price

2.2.1.3.2. Quality

2.2.1.3.3. Speed

2.2.1.3.4. Dependability

2.2.1.3.5. Flexibility

2.2.1.4. Aspects of Operations management

2.2.1.4.1. Vertical integration strategy

2.2.1.4.2. Facilities

2.2.1.4.3. Technology strategy

2.2.1.4.4. Workforce organization

2.2.1.4.5. Inventory management

2.2.1.4.6. Business Control Principles

2.2.1.4.7. Management Control Implementation

2.2.2. Outsourcing

2.2.2.1. Asset Support Agreements

2.2.2.1.1. Over-the-counter support

2.2.2.1.2. Field Service Support

2.2.2.1.3. Performance contracts

2.2.2.1.4. Consignment stock

2.2.2.1.5. Pay-per-use

2.2.2.2. Out-sourcing vs insourcing

2.3. 2.3 Lifecycle Value Realization

2.3.1. Product Lifecycle Management Approach

2.3.1.1. Stages of PLM and problems

2.3.1.1.1. Imagine

2.3.1.1.2. Define

2.3.1.1.3. Realise

2.3.1.1.4. Support/Use

2.3.1.1.5. Decomissioning

2.3.2. Alternatice Approach

2.3.2.1. Asset Need Identification

2.3.2.2. Asset Selection

2.3.2.3. Asset Procurement

2.3.2.4. Asset Operations

2.3.2.5. Asset Maintenance

2.3.2.6. Asset Life Extension

2.3.2.7. Asset Disposal and Decommisioning

2.3.3. Business Processes

2.3.3.1. Maintenance

2.3.3.2. Engineering change management

2.3.3.3. Phase-out

2.3.3.4. Standardization

2.3.4. Dimenstions of PLM

2.3.4.1. Objectives & Metrics

2.3.4.2. Management & Organization

2.3.4.3. People

2.3.4.4. Methods

2.3.4.5. Facilities & Equipment

2.3.4.6. Product Data

2.3.5. 12 Principles of PLM

2.4. 2.4 Resourcing Strategy

2.4.1. Process driven strategy

2.4.2. Process Mapping Techniques

2.4.3. Case study

2.5. 2.5 Shutdown and Outage Strategy

2.5.1. Scheduling Principles

2.5.2. Project Management fundamentals

2.5.3. Using MS Project

2.5.4. Project scoping: charter

2.5.5. Stakeholder management

2.5.6. Work Breakdown Structure

2.5.7. Work sequencing

2.5.8. Resource leveling

2.5.9. Project control

2.5.10. Project close-out

3. 3. LIFECYCLE DELIVERY

3.1. 3.1 Technical Standards & Legislation

3.1.1. What are technical standards and regulations

3.1.2. Internal regulations

3.1.2.1. Systems integration

3.1.2.2. Asset Management controls

3.1.2.3. Code of Practice - South Africa Mines

3.1.2.4. Procurement Policy

3.1.2.4.1. Procurement Methods and Types

3.1.2.4.2. Procurement Guidelines

3.1.2.5. Code of Practice for Mines

3.1.2.5.1. Content for COP: Anglo American

3.1.3. National standardss and regulations

3.1.3.1. Mine Health and Safety Act

3.1.3.1.1. Scope and Application

3.1.3.1.2. Basis for Asset Management

3.1.3.2. Basic Conditions of Employement Act

3.1.3.2.1. Scope and Application

3.1.3.2.2. Basis for Asset Management

3.1.3.3. Ocuppational Health and Safety Act

3.1.3.3.1. Scope and Application

3.1.3.3.2. Basis for Asset Management

3.1.3.4. Othe Industrial Regulations

3.1.3.4.1. General Machinery Regulations

3.1.3.4.2. Pressure Equipment

3.1.3.4.3. Driven Machinery Regulations

3.1.3.4.4. Competency Regulations

3.1.4. International Standards

3.1.4.1. ISO 55000

3.1.4.2. ISO 14000

3.1.4.3. ISO 9000

3.1.4.4. ISO 15000

3.2. 3.2 Asset Creation & Acquisition

3.2.1. Capital Investment Decision Making

3.2.1.1. Basic Knowledge on Evaluation Methods

3.2.1.1.1. Payback Period

3.2.1.1.2. Net Present Value

3.2.1.1.3. Return on Investement

3.2.1.1.4. Internal Rate of Return

3.2.2. Life Cycle Costing

3.2.2.1. Freight

3.2.2.2. Installation

3.2.2.3. Commisioning and Installations

3.2.2.3.1. Full purpose of commisioning

3.2.2.3.2. Warranty and warranty management

3.2.2.4. Cost validations and benchmarking

3.2.3. Asset Creation Phases

3.2.3.1. Conceptualisation

3.2.3.2. Definition

3.2.3.3. Implementation

3.2.3.4. Hand-over

3.3. 3.3 Systems Engineering

3.3.1. What is system thinking

3.3.2. SEBOK Principles of System Thinking

3.3.3. EN50126 V Diagram

3.3.4. What is a system

3.3.5. Scope of Systems Engineering

3.3.5.1. Example of disasters where system engineering could have avoided

3.3.5.2. NASA Mission Control Method

3.3.5.3. Charecteristics of System Engineers

3.3.6. Types of Systems

3.3.6.1. Deterministic

3.3.6.2. Stachostic

3.3.6.3. Emergent

3.3.7. Charecteristics of Complex Systems

3.3.8. System Management Tools

3.3.9. System modeling

3.3.9.1. Context Diagram

3.3.9.2. Interaction with externalities

3.3.9.3. Interaction between sub-systems

3.3.9.4. Functional Analysis

3.3.9.4.1. Functional decomposition

3.3.9.4.2. FFBD Numbering Convention

3.3.9.4.3. Flow Formatting

3.3.9.4.4. Functional modeling and Process Mapping

3.3.9.4.5. Uses of Functional Mapping

3.3.9.4.6. Functional mapping Case Studies

3.3.9.5. Introduction to Processes

3.3.9.5.1. Function decomposition

3.3.9.5.2. Inputs

3.3.9.5.3. Process function

3.3.9.5.4. Outputs

3.3.9.5.5. Storage

3.3.9.5.6. Flow

3.3.9.5.7. External entities

3.3.9.6. Reliability Engineering as System Tool

3.3.9.6.1. Functional mapping

3.3.9.6.2. Application: Fault Tree Decision maps

3.3.9.6.3. Redundency

3.3.9.7. Lifecycle system interactions

3.4. 3.4 Configuration Management

3.4.1. Definition and purpose

3.4.2. Change triggers in asset management

3.4.3. 5 Elements of configuration Management

3.4.3.1. Configuration management and planning

3.4.3.1.1. Establishing documented controls

3.4.3.1.2. Critical Point Point Control Approach

3.4.3.2. Configuration identification

3.4.3.2.1. Audits

3.4.3.2.2. Source documents

3.4.3.3. Configuration control

3.4.3.3.1. Processing

3.4.3.3.2. Approval

3.4.3.3.3. Standards commitees

3.4.3.3.4. Identyfing system interfaces to the change

3.4.3.3.5. Fault-proofing

3.4.3.3.6. Communication

3.4.3.4. Configuration status accounting

3.4.3.4.1. Using CMMS to document

3.4.3.5. Configuration verification & audits

3.4.3.5.1. Operational verification

3.4.3.5.2. Post implementation monitoring

3.4.3.5.3. Post implementation support

3.5. 3.5 Maintenance Delivery

3.5.1. Maintenance Resources and Processes

3.5.1.1. People, Skills, Availability

3.5.1.2. Information, communication, platforms

3.5.1.3. Logistics, parts, suppliers

3.5.1.4. Facilities: tools, technologies, infrustructure

3.5.2. Cross functional cordination

3.5.3. Maintenace Plan

3.5.3.1. Development

3.5.3.2. Optimization

3.5.3.2.1. Project identification tools and triggers

3.5.3.2.2. RCM

3.5.3.2.3. Types of Maintenace Tasks

3.5.4. Scheduling and Planning

3.5.4.1. Operational alignments

3.5.4.2. Shifts and after-hour support

3.5.4.3. Oppotune maintenance in fulco operations

3.6. 3.6 Reliability Engineering

3.6.1. Definition and Purpose

3.6.1.1. Reliability unpacked

3.6.2. Building reliability in design

3.6.3. Understanding failure

3.6.3.1. Effects of production disruptions

3.6.3.2. Continous degradation

3.6.3.3. Descrete failure

3.6.3.4. Measures of reliability

3.6.3.4.1. Failure frequency

3.6.3.4.2. Mean-time between failures

3.6.4. Failure modes

3.6.4.1. FMEA

3.6.4.2. FMECA

3.6.4.3. Root cause analysis method

3.6.5. Reliability Systems

3.6.5.1. Series Systems

3.6.5.2. Parallel Systems

3.6.5.3. Stand-by Systems

3.6.5.4. Bayes' Therem

3.6.6. The reliability functions

3.6.6.1. The exponential reliability function

3.6.6.2. System reliability vs. reliability of components

3.6.6.3. Reliability and unreliability enumerated

3.6.6.4. The hazard function

3.6.6.5. The general reliability function

3.6.6.6. Failure density function

3.6.7. Reliability MathematicsProbability Concepts

3.6.7.1. Continuous Distribution Functions

3.6.7.2. Statistical Confidence

3.6.7.3. Goodness of Fit

3.6.7.4. Point Processes

3.6.8. Lifetime DistributionsDiscrete Distributions

3.6.8.1. System Lifetime Distributions

3.6.8.2. Discrete distrubutions

3.6.9. The Maintenance Connection

3.6.9.1. Preventive Maintenance Strategy

3.6.9.2. FMEA, FMECA

3.6.9.3. The role of RCM

3.6.9.4. Maintainability

3.6.9.5. Integrated Logistic Suppor

3.6.10. Parametric Lifetime ModelsExponential Distribution

3.6.10.1. Weibull Distribution

3.6.10.2. Other Lifetime Distributions

3.6.11. Probability Plotting

3.6.11.1. Ranking of Data

3.6.11.2. Lognormal Plots

3.6.11.3. Weibull Plots

3.6.11.4. Extreme Value plotting

3.6.11.5. Hazard plotting

3.6.12. Analysing Reliability Data

3.6.12.1. Pareto Analysis

3.6.12.2. Accelerated Test Data Analysis

3.6.12.3. CUSUM Charts

3.6.12.4. Reliability Demonstration

3.6.12.5. Jack Knife Plots

3.6.13. Lifetime Data Analysis

3.6.13.1. Point estimation

3.6.13.2. Interval estimation

3.6.13.3. Likelihood Theory

3.6.13.4. Censoring

3.6.13.5. Choice of time between overhauls

3.6.14. Reliability Improvement Fundamentals

3.6.14.1. Reliability and Integrity Growth

3.6.14.2. The use of SWIFT (Structured what if technique)

3.6.15. The bridge between material / equipment degradation and unreliability

3.6.15.1. Degradation rate modelling

3.6.15.2. Degradation Mechanisms

3.6.15.3. Time-to-failure modelling

3.6.15.4. Advanced Analysis

3.6.15.5. Competing Risks

3.6.15.6. Accelerated Life

3.6.15.7. Reliability Analysis of Repairable Systems

3.6.15.8. Proportional Hazards Modelling

3.6.15.9. Parametric Estimation for models without covariatesExponential Distribution

3.6.15.10. Weibull Distribution

3.6.16. Parametric Estimation for models with covariates

3.6.16.1. Accelerated Life

3.6.16.2. Proportional Hazards Modelling

3.6.17. Assessing model adequacy

3.6.17.1. Chi-Square Test

3.6.17.2. Kolmogorov-Smirnov

3.6.17.3. Confidence Limits

3.6.18. Reliability Management

3.6.19. Reliability Policy

3.6.19.1. Integrated Reliability Programmes

3.6.19.2. Measuring reliability

3.6.19.3. Specifying Reliability

3.6.19.4. Managing Suppliers

3.6.19.5. The Reliability Manual

3.7. 3.7 Asset Operations

3.8. 3.8 Resource Management

3.9. 3.9 Shutdown & Outage Management

3.10. 3.10 Fault & Incident Response

3.11. 3.11 Asset Decommissioning & Disposal

4. 4. ASSET INFORMATION 😍

4.1. 4.1 Asset Information Strategy

4.1.1. What does an Asset Information Strategy Solve

4.1.1.1. Speed of insight generation

4.1.1.2. Consistent data quality

4.1.1.3. Fit-for-purpose monitoring and control solutions

4.1.1.4. Increase in delivery platforms

4.1.2. Scale and volume of Asset Management Data

4.1.2.1. Structured and unstructured data

4.1.2.2. The Plothera of Asset Management Data

4.1.2.3. Complexity of Big Data

4.1.2.4. Analytical challenges

4.1.3. Defining an Information Strategy

4.1.4. Elements of Information Strategy

4.1.4.1. Business Requirements

4.1.4.1.1. On-going operational needs

4.1.4.1.2. Planning Information

4.1.4.1.3. Ad-hoc Reporting

4.1.4.2. Data Sourcing Plan

4.1.4.2.1. Incoporating data in Acquisition Plan

4.1.4.2.2. Mapping data sources in Business Process Analysis

4.1.4.2.3. Metadata mangement

4.1.4.2.4. Communication Plans

4.1.4.3. Technology Infrastructure Requirements

4.1.4.3.1. Enterprise Resource Planning Tool

4.1.4.3.2. Computerised Maintenance Management System

4.1.4.3.3. Customer Relatioship Management

4.1.4.3.4. Integration

4.1.4.3.5. ETL Tools

4.1.4.3.6. Analysis Tools

4.1.4.3.7. Reporting Tools

4.1.4.3.8. Data Lakes

4.1.4.3.9. Skills

4.1.4.4. Generating Insights

4.1.4.4.1. Decentralised vs centralised approach

4.1.4.4.2. Types of Analytics

4.1.4.4.3. Visualization

4.1.4.4.4. Machine Learning

4.1.4.4.5. Time value of data

4.1.4.5. People and Processes

4.1.4.5.1. Change management

4.1.4.6. Data Governance

4.1.4.6.1. Data Management

4.1.4.6.2. Business Processes

4.1.4.6.3. Compliance

4.1.4.6.4. People Management

4.1.4.7. Roadmap

4.1.4.7.1. Pilot

4.1.4.7.2. Project Management

4.2. 4.2 Asset Information Standards

4.2.1. ISO 14224

4.2.1.1. Objectives

4.2.1.1.1. Specify data to be analysed in asset management

4.2.1.1.2. To specify data in a standard format

4.2.1.1.3. Data Quality Dimensions

4.2.1.2. Equipment boundary and Hiearchy

4.2.1.2.1. Hiearchy

4.2.1.2.2. Plant to Spare part levels

4.2.1.2.3. Unit Entity

4.2.1.3. Data Categories

4.2.1.3.1. Equipment Data

4.2.1.3.2. Failure Data

4.2.1.3.3. Maintenance Data

4.2.1.4. Data Format Rules

4.2.1.4.1. Ease of Input

4.2.1.4.2. Facilitation of query and analysis

4.2.1.4.3. Consistency check

4.2.1.5. Database Structure

4.2.1.5.1. Data architecture

4.2.1.5.2. Normalization

4.3. 4.3 Asset Information System

4.3.1. What it is : CMMS

4.3.2. Function and Applications

4.3.2.1. Asset Register including listing of maintainable assets

4.3.2.2. Routine Maintenance Lists

4.3.2.3. Routine Maintenance Prompts

4.3.2.4. Work Requests

4.3.2.5. Work Order Management

4.3.2.6. Data Logging

4.3.2.7. Estimating, Costing and Cost Reports

4.3.2.8. Budgeting, budgetary reports

4.3.2.9. Spare Parts and Consumables Inventory Management.

4.3.2.10. Suppliers, Purchasing.

4.3.2.11. Global Positioning Systems

4.3.3. Some common and local asset information systems

4.3.4. Data & Information Management

4.3.4.1. Identification of information needs;

4.3.4.2. Acquisition and creation of information;

4.3.4.3. Analysis and interpretation of information;

4.3.4.4. Organization and storage of information;

4.3.4.5. Information access and dissemination;

4.3.4.6. Information use

4.4. 4.4 Data & Information Management

5. 5. ORGANIZATION & PEOPLE

5.1. 5.1 Procurement and Supply Chain

5.1.1. Strategic Persepctive

5.1.1.1. Scope & Influence of Procurement on Asset Management

5.1.1.2. The procurement function

5.1.1.3. Strategic function of procurement

5.1.1.3.1. Due deligence

5.1.1.3.2. Supply chain risk management

5.1.1.3.3. Relationship management

5.1.1.3.4. Continous supply chain improvement

5.1.1.3.5. Inventory investment

5.1.1.3.6. Procurement expertise

5.1.1.4. Types of buyers

5.1.1.5. Sourcing vs Procurement

5.1.1.6. Strategic Maturity Levels of Procurement

5.1.1.6.1. Procurement factors today

5.1.1.6.2. Measures of good Procurement

5.1.1.7. Strategic Procurement

5.1.1.7.1. Understanding strategy

5.1.1.7.2. Relational Planning and its limitations

5.1.1.7.3. Levels of organisational strategies

5.1.1.7.4. Growth strategies

5.1.1.7.5. Procurement Strategy Examples

5.1.1.7.6. Micro Environment Factors

5.1.1.7.7. Culture

5.1.1.7.8. Critical Success Factors of Procurement

5.1.1.8. Logistics and Supply Chain

5.1.1.8.1. What is Logistics

5.1.1.8.2. Scope of Logistics Management

5.1.1.8.3. Supply chains

5.1.1.8.4. Logistics 1

5.1.1.8.5. Logistics 2

5.1.2. Supplier Focus

5.1.2.1. Supplier Relationship and Partnership

5.1.2.2. Contracts

5.1.2.3. Quality Management

5.1.2.4. Supply- Demand Matching

5.1.2.5. Sourcing

5.1.2.6. Price Management

5.1.3. General Procurement

5.1.3.1. Project Procurement

5.1.3.2. Global Sourcing

5.1.3.3. Negotiations

5.1.3.4. Contract Management

5.1.3.5. Category and Commodity Procurement

5.1.3.6. World Class Practices

5.1.3.7. Asset Management Leadership

5.1.3.8. Organizational Structure

5.1.3.9. Organizational Culture

5.1.3.10. Competence Management

5.2. 5.2 Asset Management Leadership

5.2.1. Leadership vs Management

5.2.1.1. Management Function

5.2.1.1.1. Plan

5.2.1.1.2. Control

5.2.1.1.3. Organize

5.2.1.2. Leadership Function

5.2.1.2.1. Decisions

5.2.1.2.2. Vision

5.2.1.2.3. Goal Setting

5.2.1.2.4. Inspire enthuthiasm

5.2.1.3. Types of Leadership Styles

5.2.1.4. Idea to Action: Leadership, management to execution

5.3. 5.3 Organizational Structure

5.3.1. Factors that influence organizational structure

5.3.2. Types of Structures

5.3.2.1. Hierarchical org structure

5.3.2.2. Functional org structure

5.3.2.3. Horizontal or flat org structure

5.3.2.4. Divisional org structures (market-based, product-based, geographic)

5.3.2.5. Matrix org structure

5.3.2.6. Team-based org structure

5.3.2.7. Network org structure

5.3.3. Asset Management Roles

5.3.3.1. Strategic roles

5.3.3.2. Tactical roles

5.3.3.3. Operational roles

5.4. 5.4 Organizational Culture

5.4.1. Why is culture relevant in Asset Management

5.4.1.1. Fighting culture

5.4.1.2. Destroying old culture

5.4.1.3. Giving in to the culture

5.4.1.4. Evolving the culture

5.4.2. What is culture

5.4.2.1. Structure

5.4.2.1.1. Visible culture

5.4.2.1.2. Beliefs and values

5.4.2.1.3. Underlying assumptions

5.4.2.2. Cultural issues

5.4.2.3. Elements of culture

5.4.2.4. Dimensions of culture

5.4.2.4.1. Hofstede Cutural Dimensions

5.4.3. How Leadership and Culture Interact

5.4.3.1. Case studies

5.4.4. Where does culture reside?

5.4.5. Culture creation, evolution and change

5.4.6. Cultural dynamics

5.4.7. Cultural dynamics for Asset Managers

5.4.8. Creating Safety

5.5. 5.5 Competency Management

5.5.1. Definition

5.5.2. When/ How do comptency issues arise?

5.5.3. What are the syptoms of imcompetency

5.5.4. Competency development process

5.5.4.1. Preparation

5.5.4.1.1. Information

5.5.4.1.2. Scope

5.5.4.1.3. Purpose

5.5.4.1.4. Problem definition

5.5.4.2. Information collection

5.5.4.2.1. Observation

5.5.4.2.2. Talk

5.5.4.2.3. Analysis

5.5.4.3. Building Competency Framework

5.5.4.3.1. Aspects of a competency frame work

5.5.4.4. Implementing competency development framework

5.5.4.4.1. Competence and business needs

5.5.4.4.2. Job specifications and recruitment

5.5.4.4.3. Rewards

5.5.4.4.4. Coaching

5.5.4.4.5. Training

5.5.4.4.6. Transperancy

6. 6. RISK AND REVIEW

6.1. 6.1 Risk Assessment and Management

6.1.1. Introduction

6.1.1.1. Risk Assessment and Management

6.1.1.2. What is risk?

6.1.1.3. How is risk identified?

6.1.1.4. Why and when to do risk analyis?

6.1.2. Uncertainty types

6.1.3. Risk management

6.1.3.1. Risk identification

6.1.3.2. Risk estimation

6.1.3.3. Risk management objectives

6.1.3.4. Risk information

6.1.3.5. Risk evaluation

6.1.3.6. Risk control

6.1.3.7. Risk monitoring

6.1.3.8. Risk communication

6.1.3.8.1. Internal

6.1.3.8.2. External

6.1.4. Risk assesement

6.1.4.1. Definition

6.1.4.2. Purpose

6.1.4.3. Main activities of risk assesment

6.1.4.3.1. Understandanding risk nature

6.1.4.3.2. Identifying the risk source

6.1.4.3.3. Consequence assesment

6.1.4.3.4. Likelihood assesment

6.1.4.3.5. Exposure assesment

6.1.4.4. Risk Charecterization

6.1.4.5. Risk Assesment methods

6.1.4.5.1. Qualitative methods

6.1.4.5.2. Quantitative methods

6.1.5. Risk Communcation

6.1.5.1. Internal

6.1.5.2. External

6.2. 6.2 Contingency Planning & Resilience Analysis

6.2.1. What is contigency planning

6.2.2. Contigency planning programme

6.2.3. Key aspects of contigency planning

6.2.4. Making assumptions

6.2.5. Risk Assesment and vulnerability analysis

6.2.6. Hazard types

6.2.7. Critical process identification

6.2.8. Business impact analysis

6.2.9. Emergency response

6.2.10. Incident and crises management

6.2.11. Incident analysis

6.2.12. Business resumption plans

6.2.13. Post event evaluation

6.3. 6.3 Sustainable Development

6.3.1. Introduction

6.3.1.1. Whats is sustainable development

6.3.1.2. Economic growth

6.3.1.3. Continuing poverty in the midst of plenty

6.3.1.4. The downside of economic development

6.3.2. Pathways to sustainable development

6.3.3. An unequal world

6.3.3.1. The extend of inequalities

6.3.3.2. Measuring inequality

6.3.3.3. Measuring well-being

6.3.3.4. Inequality within countries

6.3.3.5. Rural- urban inequality

6.3.4. Why some countries developed while others stayed poor

6.3.4.1. Clinical economics

6.3.4.2. Main factors

6.3.4.3. Culture

6.3.4.4. Politics

6.3.4.5. Why other countries are still stuck in poverty

6.3.5. Climate chage

6.3.5.1. The basic of climate change

6.3.5.2. Human induced climate change

6.3.5.3. Industrial mitigation of climate change

6.3.5.4. The 2 degree target

6.3.6. Sustainable development goals

6.3.6.1. The SDG Goals

6.3.6.2. Corporate adoptation

6.4. 6.4 Management of Change

6.4.1. Change management theory

6.4.1.1. Individual change

6.4.1.2. Team change

6.4.1.3. Organizational change

6.4.1.4. Leading change

6.4.2. Change management in action

6.4.2.1. Restructuring

6.4.2.2. Cultural change

6.4.2.3. Change management Case studies in Asset Management

6.5. 6.5 Assets Performance & Health Monitoring

6.5.1. The need for performance mmeasurement

6.5.2. How maintenance measures fit in organizational performance

6.5.3. Typical maintenance measures

6.5.3.1. Machine / facilities efficiciency

6.5.3.2. Task efficinecy

6.5.3.3. Organisational efficincy

6.5.3.4. Financial efficiency

6.5.3.5. Maintenance results

6.5.3.6. Maintenance operational purposefulness

6.5.3.7. Overall maintenance performance system

6.5.4. Lagging vs leading measures

6.5.5. Implementing a reporting systems

6.5.6. Business Controls in asset management

6.6. 6.6 Asset Management System Monitoring

6.6.1. Overaching policy objectives

6.6.2. Targets and result

6.6.3. Reformulating new measures

6.6.4. Audit results integration

6.6.5. Performance indices integration

6.7. 6.7 Management Review, Audit & Assurance

6.7.1. The need for auditing

6.7.2. Auditing standards

6.7.2.1. What to compare against

6.7.2.2. Setting audit objectives

6.7.2.3. Types of audits

6.7.2.4. Audits vs Assurance

6.7.2.5. General considerations in an assurance engagement

6.7.2.6. Defining internal controls

6.7.2.6.1. Components of internal controls

6.7.2.6.2. Monitoring of controls

6.7.2.6.3. Monitoring controls

6.7.2.6.4. Hard and soft controls

6.7.2.7. Audit areas

6.7.2.7.1. Administration

6.7.2.7.2. Expertise and competence

6.7.2.7.3. Facilities

6.7.2.7.4. Management process

6.7.2.7.5. Maintenance policy setting

6.7.2.7.6. Organizational climate and culture

6.7.2.7.7. House keeping

6.8. 6.8 Asset Costing & Valuation

6.8.1. Purpose of costing and valuation

6.8.2. Cost method valuation

6.8.3. Market value method

6.8.4. Standard stock method

6.9. 6.9 Stakeholder Engagement

6.9.1. The Asset Stakeholder Plan

6.9.1.1. Purpose of Stakeholder Plan

6.9.1.2. Components of Stakeholder Plan

6.9.1.2.1. Identification

6.9.1.2.2. Analysis

6.9.1.2.3. Assessement

6.9.1.2.4. Treatment and control

6.9.1.2.5. Attributes of Stakeholder Plan

6.9.1.3. The planning process

6.9.2. RACI Matrix

6.9.3. What is a communication plan

6.9.4. The 10 Principles of Stakeholder Engagement