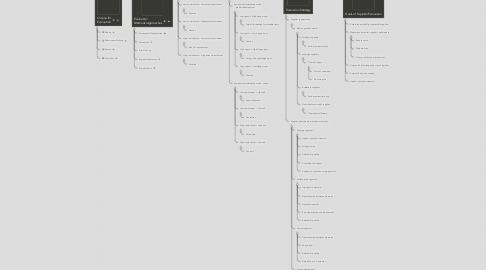

1. Goals of Supplier Evaluation

1.1. Ensure the availability of potential suppliers

1.2. Measure and monitor supplier's performance

1.2.1. Reduce costs

1.2.2. Mitigate risks

1.2.3. Driving continuous improvement

1.3. Deepen the knowledge about each supplier

1.4. Assist with decision making

1.5. Highest priority to measure

2. Evaluation Strategy

2.1. Supplier segmentation

2.1.1. Kraljic’s portfolio model

2.1.1.1. Strategic suppliers

2.1.1.1.1. Performance evaluation.

2.1.1.2. Leverage suppliers

2.1.1.2.1. Financial impact

2.1.1.3. Bottleneck suppliers

2.1.1.3.1. Performance monitoring

2.1.1.4. Noncritical/commodity suppliers

2.1.1.4.1. Operational efficiency

2.2. Supplier performance management actions

2.2.1. Strategic segment

2.2.1.1. Highest priority to measure

2.2.1.2. Strategic value

2.2.1.3. Relationship quality

2.2.1.4. Contribute to business

2.2.1.5. Emphasis on continuous improvement

2.2.2. Collaborative segment

2.2.2.1. Important to measure

2.2.2.2. Operational performance measures

2.2.2.3. Financial measures

2.2.2.4. Encourage continuous improvement

2.2.2.5. Relationship quality

2.2.3. Custom segment

2.2.3.1. Operational performance measures

2.2.3.2. Service level

2.2.3.3. Relationship quality

2.2.3.4. Reliability - avoid surprises

2.2.4. Commodity segment

2.2.4.1. Lowest priority to measure

2.2.4.2. Focus on operational performance basics

2.2.4.3. Measure internal stakeholder satisfaction

3. Criteria for Evaluation

3.1. Quality

3.2. Performance Delivery

3.3. Service

3.4. Price/Cost

4. Evaluation Methods/Approaches

4.1. Surveys and Qestionnaires

4.2. Scorecards

4.3. Site Visits

4.4. Supplier Assesment

4.5. Supplier Audit

5. Supplier commitment matrix

5.1. Low commitment + Low actual commitment

5.1.1. Maintain

5.2. Low commitment + High actual commitment

5.2.1. Caution

5.3. High commitment + Low actual commitment

5.3.1. Plan for improvement

5.4. High commitment + High actual commitment

5.4.1. Maintain

6. Other ways

6.1. Supplier characterization matrix - product development

6.1.1. Low spend + High design input

6.1.1.1. Target for redesign for standard items

6.1.2. Low spend + Low design input

6.1.2.1. Caution

6.1.3. High spend + High design input

6.1.3.1. Savings through design input

6.1.4. High spend + Low design input

6.1.4.1. Maintain

6.2. Supplier characterization matrix - spend

6.2.1. Low commitment + High risk

6.2.1.1. Special attention

6.2.2. Low commitment + Low risk

6.2.2.1. Transaction

6.2.3. High commitment + High risk

6.2.3.1. Partnership

6.2.4. High commitment + Low risk

6.2.4.1. Contract