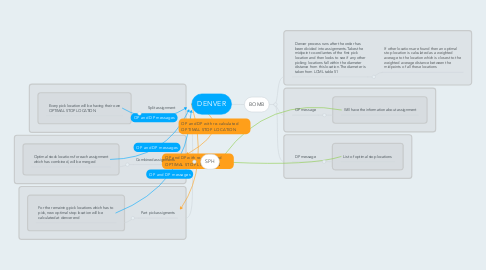

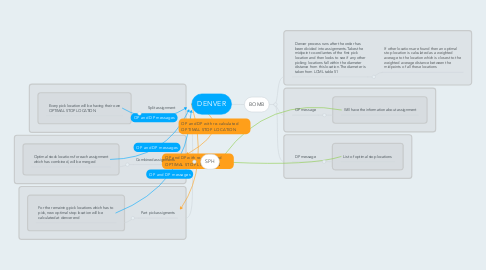

DENVER

by haritha polose

1. SPH

1.1. Split assignment

1.1.1. Every pick location will be having their own OPTIMAL STOP LOCATION

1.2. Combined assignments

1.2.1. Optimal stock locations for each assignment which has combined, will be merged

1.3. Part pick assigments

1.3.1. For the remaining pick locations which has to pick, new optimal stop location will be calculated at denver end

2. BOMB

2.1. Denver process runs after the order has been divided into assignments.Takes the midpoint co-ordiantes of the first pick location and then looks to see if any other picking locations fall within the diameter distance from this location.The diameter is taken from LCML table 51

2.1.1. If other locations are found then an optimal stop location is calculated as a weighted average to the location which is closest to the weighted average distance between the midpoints of all these locations

2.2. OP message

2.2.1. Will have the information about assignment

2.3. DP message

2.3.1. List of optimal stop locations