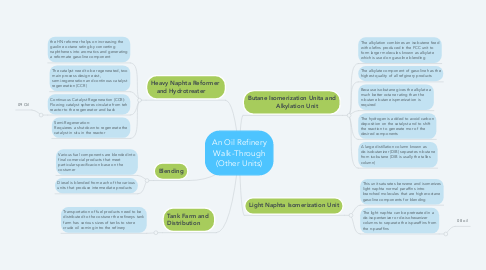

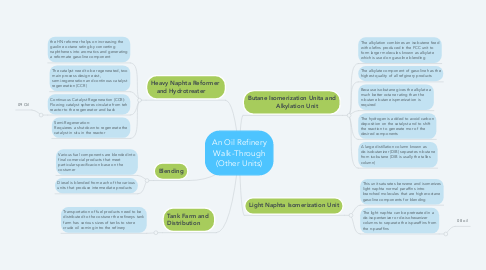

An Oil Refinery Walk-Through (Other Units)

by Brian Nunez

1. Heavy Naphta Reformer and Hydrotreater

1.1. the HN reformer helps on increasing the gaoline octane rating by converting naphthenes into aromatics and generating a reformate gasoline component

1.2. The catalyst need to be regenerated, two main process design exist, semi-regeneration and continous catalyst regeneration (CCR)

1.3. Continuous Catalyst Regeneration (CCR): Flowing catalyst spheres circulate from teh reactor to the regenerator and back

1.3.1. 09 Oil

1.4. Semi-Regeneration: Requieres a shutdown to regenerate the catalyst in situ in the reactor

2. Blending

2.1. Various fuel components are blended into final comercial products that meet particular specificacion base on the costumer

2.2. Diesel is blended from each of the various units that produce intermediate products

3. Tank Farm and Distribution

3.1. Transportation of fuel products need to be distributed to the costuner the refinerys tank farm has various sizes of tanks to store crude oil coming intro the refinery

4. Butane Isomerization Unita and Alkylation Unit

4.1. The alkylation combines an isobutene feed with olefins produced in the FCC unit to form larger molecules known as alkylate which is used on gasoline blending

4.2. The alkylate component of gasoline has the highest quality of all refginery products

4.3. Because isobutane gives the alkylate a much better octane rating than the n-butane butane ispmerization is required

4.4. The hydrogen is added to avoid carbon deposition on the catalyst and to shift the reaction to generate mor of the desired components

4.5. A large distillation column known as de-isobutanizer (DIB) separates n-butane from isobutane (DIB is usally the talles column)

5. Light Naphta Isomerization Unit

5.1. This unit saturates benzene and isomerizes light naphta normal paraffins intro branched molecules that are higher-octane gasoline components for blending

5.2. The light naphta can be pretreated in a de-isopentanizer or de-isohexanizer columns to separate the isparaffins from the n-paraffins

5.2.1. 08 oil