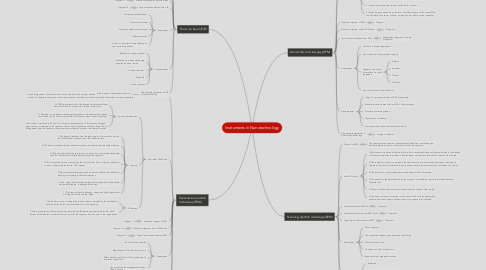

1. Transmission electron microscope (TEM)

1.1. Principle of TEM

1.1.1. A high energy beam of electrons is shone through a very thin sample, and the interactions between the electrons and the atoms can be used to observe features such as the crystal structure and features in the structure like dislocations and grain boundaries.

1.2. How does TEM works

1.2.1. Specimen Preparation

1.2.1.1. 1) A TEM specimen must be thin enough to transmit sufficient electrons to form an image with minimum energy loss.

1.2.1.2. 2) Dimpling is a preparation technique that produces a specimen with a thinned central area and an outer rim of sufficient thickness to permit ease of handling.

1.2.1.3. 3) Ion milling is traditionally the final form of specimen preparation. In this process, charged argon ions are accelerated to the specimen surface by the application of high voltage. The ion impingement upon the specimen surface removes material as a result of momentum transfer

1.2.2. Imaging

1.2.2.1. 1) The beam of electrons from the electron gun is focused into a small, thin, coherent beam by the use of the condenser lens.

1.2.2.2. 2) This beam is restricted by the condenser aperture, which excludes high angle electrons.

1.2.2.3. 3) The beam then strikes the specimen and parts of it are transmitted depending upon the thickness and electron transparency of the specimen.

1.2.2.4. 4) This transmitted portion is focused by the objective lens into an image on phosphor screen or charge coupled device (CCD) camera.

1.2.2.5. 5) Optional objective apertures can be used to enhance the contrast by blocking out high-angle diffracted electrons.

1.2.2.6. 6) The image then passed down the column through the intermediate and projector lenses, is enlarged all the way.

1.2.2.7. 7) The image strikes the phosphor screen and light is generated, allowing the user to see the image.

1.2.3. Diffraction

1.2.3.1. 1) As the electrons pass through the sample, they are scattered by the electrostatic potential set up by the constituent elements in the specimen.

1.2.3.2. 2) After passing through the specimen they pass through the electromagnetic objective lens which focuses all the electrons scattered from one point of the specimen into one point in the image plane.

1.3. Schematic diagram of TEM

1.3.1. Diagram 7

1.4. Schematic diagram on how TEM works

1.4.1. Diagram 8

1.5. Type of results obtained from TEM

1.5.1. Diagram 9

1.6. Advantages

1.6.1. Use thinly sliced samples

1.6.2. Magnification of 10,000 times or more

1.6.3. Offers excellent resolution of the crystallographic structure of specimens

1.6.4. Can even show the arrangement of atoms within a sample

1.7. Disadvantages

1.7.1. Cannot be used to observe living specimens

1.7.2. Some delicate samples may also be damaged by the electron beam

1.7.3. Samples must first be stained or coated with a chemical to protect them, but sometimes this treatment also destroys the specimen

1.8. One example application of TEM in nanotechnology

1.8.1. Nano-size membrane

2. Focus ion beam (FIB)

2.1. Principle of FIB

2.1.1. Use a finely focused beam of ions (usually gallium) that can be operated at low beam currents for imaging or high beam currents for site specific sputtering or milling.

2.2. How FIB works

2.2.1. 1) When the high-energy gallium ions strike the sample, they will sputter atoms from the surface.

2.2.2. 2) Gallium atoms will also be implanted into the top few nanometers of the surface, and the surface will be made amorphous.

2.3. Schematic diagram of FIB

2.3.1. Diagram 10

2.4. Schematic diagram on how FIB works

2.4.1. Diagram 11

2.5. Type of results obtained from FIB

2.5.1. Diagram 12

2.6. Advantages

2.6.1. Computer-controlled beam

2.6.2. No mask is needed

2.6.3. Diffraction effects are minimized

2.6.4. Higher resolution

2.6.5. Ion beam can detect surface features for very accurate registration

2.7. Disadvantages

2.7.1. Reliable ion sources needed

2.7.2. Swelling occurs when developing negative ion beam resists

2.7.3. Limiting resolution

2.7.4. Expensive

2.7.5. Slower process

2.8. One example application of FIB in nanotechnology

2.8.1. In fabrication of semiconductor device

3. Atomic force microscopy (AFM)

3.1. Principle of AFM

3.1.1. A sharp cantilever tip interacts with the sample surface without using light.

3.2. How AFM works

3.2.1. 1) AFM works by bringing an atomically sharp tip close to a surface.

3.2.2. 2) There is an attractive force between the tip and the surface and this force is kept the same throughout the experiment.

3.2.3. 3) As the probe tip scans back and forth over the surface, the tip will rise and fall with the different features on the surface.

3.2.4. 4) A laser is pointed at the tip and is reflected to a sensor.

3.2.5. 5) As the tip goes up and down the laser hits different parts of the sensor. With the information the sensor collects, an image of the surface can be recreated.

3.3. Schematic diagram of AFM

3.3.1. Diagram 1

3.4. Schematic diagram of how AFM works

3.4.1. Diagram 2

3.5. Type of results obtained from AFM

3.5.1. Topographic images of a sample (Diagram 3)

3.6. Advantages

3.6.1. Save time in sample preparation.

3.6.2. High resolution in topographical imaging.

3.6.3. Capable in providing informations on other properties

3.6.3.1. Stiffness

3.6.3.2. Hardness

3.6.3.3. Friction

3.6.3.4. Elasticity

3.6.4. As a tool for controlled mechanical

3.7. Disadvantages

3.7.1. Image of a maximum height in 10-20 micrometers

3.7.2. Maximum scanning area of about 150×150 micrometers.

3.7.3. Slow rate of scanning speed

3.7.4. Highly-cost of cantilevers

3.7.5. Lower lateral resolution and additional artifacts.

3.8. One example application of AFM in nanotechnology

3.8.1. Imaging of polymer

4. Scanning electron microsope (SEM)

4.1. Principle of SEM

4.1.1. The specimen is exposed to a narrow electron beam from an electron gun, which rapidly moves over or scans the surface of the specimen.

4.2. How SEM works

4.2.1. 1) Electrons are produced at the top of the column, accelerated down and passed through a combination of lenses and apertures to produce a focused beam of electrons which hits the surface of the sample.

4.2.2. 2) The sample is mounted on a stage in the chamber area and, unless the microscope is designed to operate at low vacuums, both the column and the chamber are evacuated by a combination of pumps.

4.2.3. 3) The level of the vacuum will depend on the design of the microscope.

4.2.4. 4) The position of the electron beam on the sample is controlled by scan coils situated above the objective lens.

4.2.5. 5) These coils allow the beam to be scanned over the surface of the sample.

4.2.6. 6) This beam rastering or scanning, as the name of the microscope suggests, enables information about a defined area on the sample to be collected.

4.3. Schematic diagram of SEM

4.3.1. Diagram 4

4.4. Schematic diagram on how SEM works

4.4.1. Diagram 5

4.5. Type of results obtained from SEM

4.5.1. Diagram 6

4.6. Advantages

4.6.1. Easy to operate

4.6.2. The associated software make operation user-friendly.

4.6.3. Works fast, save time.

4.6.4. Generation of data in digital form

4.6.5. Require minimal preparation actions

4.7. Disadvantages

4.7.1. Expensive

4.7.2. Limited to solid, inorganic samples

4.7.3. Carry a small risk of radiation exposure associated with the electrons that scatter from beneath the sample surface

4.8. One example application of SEM in nanotechnology

4.8.1. Scanning of agriculture products, such as the surface of the apple's skin