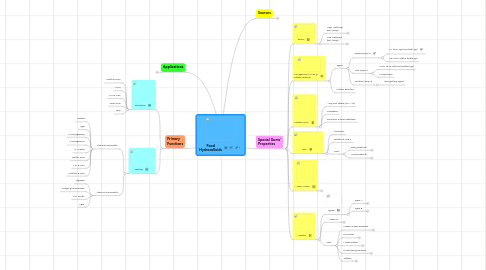

1. Sources

1.1. Natural

1.1.1. Plant parts

1.1.1.1. Pectin

1.1.1.2. Starch

1.1.1.3. Cellulose

1.1.2. Tree Sap

1.1.2.1. Gum Arabic

1.1.3. Tubers

1.1.3.1. Konjac glucomannan

1.1.4. Seeds

1.1.4.1. Guar Gum

1.1.4.2. LBG

1.1.5. Seaweeds

1.1.5.1. Carageenan

1.1.5.2. Alginate

1.1.5.3. Agar-agar

1.1.6. Microbial

1.1.6.1. Xanthan Gum

1.1.6.2. Gellan Gum

1.1.7. Animal

1.1.7.1. e.g. Gelatin

1.2. Not Natural

1.2.1. MC

1.2.2. CMC

1.2.3. MCC

1.2.4. HPC

2. Applications

2.1. Thickening

2.1.1. Sauces

2.1.2. Cake batter jams

2.1.3. Puddings and Custard

2.2. Gelling agents

2.2.1. Puddings

2.2.2. Desserts

2.2.3. Jams

2.3. Emulsifiers

2.3.1. Salad Dressing

2.3.2. Cake Mixes

2.4. Foam Stabilizer

2.4.1. Beer

2.4.2. Whipped Toppings

2.4.3. Merringues

2.5. Stabilizer

2.5.1. Pasta product

2.6. Encapsulating agents

2.6.1. Powdered flavors

2.7. Binding agents

2.7.1. Sausage

2.8. Suspending agent

2.8.1. Chocolate milk

2.8.2. Yoghurt

2.9. Crystallization Inhibitor

2.9.1. Ice cream

2.9.2. Candies

2.9.3. Sugar syrup

3. Primary Functions

3.1. Thickener

3.1.1. Xanthan Gum

3.1.2. CMC

3.1.3. MC & HPC

3.1.4. Guar Gum

3.1.5. LBG

3.2. Gelling

3.2.1. Thermal Reversible

3.2.1.1. Gelatin

3.2.1.2. Agar

3.2.1.3. K-Carrageenan

3.2.1.4. I- Carrageenan

3.2.1.5. LM Pectin

3.2.1.6. Gellan Gum

3.2.1.7. MC & HPC

3.2.1.8. Xanthan & LBG

3.2.2. Thermal Irreversible

3.2.2.1. Alginate

3.2.2.2. Konjac glucomannan

3.2.2.3. HM Pectin

3.2.2.4. LBG

4. Special Gums' Properties

4.1. Pectin

4.1.1. High Methoxyl (DE >50%)

4.1.1.1. Thermal Irreversible Gelling agent

4.1.1.1.1. High solid content (55- 85%)

4.1.1.1.2. Low pH (pH 2.8- 3.8)

4.1.1.2. Rapid set

4.1.1.2.1. Whole fruit jams

4.1.1.3. Slow set

4.1.1.3.1. Very acid foods

4.1.2. Low Methoxyl (DE <50%)

4.1.2.1. LMP

4.1.2.1.1. Thermal Reversible Gelling agent

4.1.2.2. ALMP

4.1.2.2.1. Very Ca2+ reactive

4.2. Carrageenan (15-40 % sulfate content)

4.2.1. Types

4.2.1.1. Kappa (25% S)

4.2.1.1.1. K+ form rigid & elastic gel

4.2.1.1.2. Ca+ form stiff & brittle gel

4.2.1.2. Iota (32% S)

4.2.1.2.1. Ca2+ form soft and resilient gel

4.2.1.2.2. no syneresis

4.2.1.3. Lambda (35% S)

4.2.1.3.1. Non-gelling agent

4.2.2. Protein Reactive

4.3. Xanthan Gum

4.3.1. Very acid stable (pH 1-13)

4.3.2. Thickener

4.3.3. Emulsion & foam stabilizer

4.4. LBG

4.4.1. Thickener

4.4.2. soluble at >85 C

4.4.3. Uses

4.4.3.1. Dairy products

4.4.3.1.1. protect against heat shock

4.4.3.1.2. impart desired mouthfeel

4.4.3.2. Meat products

4.4.3.2.1. water binder

4.5. Gum Arabic

4.5.1. Encapsulating flavors

4.5.2. Emulsifying beverages

4.5.3. Clarifying wines

4.5.4. Coating candy shells

4.5.5. Controlling water

4.5.6. Coating candy shells

4.6. Gelatin

4.6.1. Types

4.6.1.1. Type A

4.6.1.1.1. Derived from acid processed materials

4.6.1.1.2. e.g. Porkskin

4.6.1.1.3. pI range 7.0- 9.4

4.6.1.2. Type B

4.6.1.2.1. Derived from alkaline processed materials

4.6.1.2.2. e.g. cattle or calf hides and ossein

4.6.1.2.3. pI range 4.8- 5.5

4.6.2. SPECIAL

4.6.2.1. "Melt in the mouth" texture

4.6.2.2. Elastic gum-like texture which slowly dissolves in mouth.

4.6.2.3. Effective emulsifying & foaming agent

4.6.2.4. Able to flocculate suspended particles

4.6.3. Uses

4.6.3.1. Frozen cream products

4.6.3.1.1. Inhibit crystallization (0.25%, 250 bloom)

4.6.3.2. Ice cream

4.6.3.2.1. Inhibit crystallization ( 0.5% , 250 bloom)

4.6.3.3. Marshmallow

4.6.3.3.1. Inhibit crystallization

4.6.3.3.2. Stabilize foam

4.6.3.4. Novel dairy products

4.6.3.4.1. creamier stir yoghurts

4.6.3.5. Toffees

4.6.3.5.1. Improve fat dispersion

4.6.3.5.2. stabilize texture of soft toffes