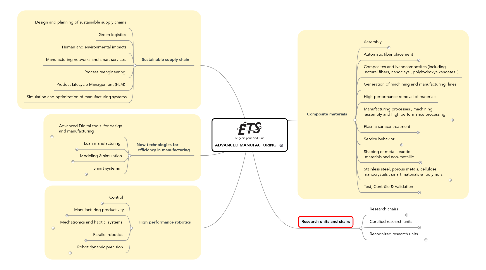

1. Composite materials

1.1. Assembly

1.1.1. Analysis of real structures

1.1.2. Design and manufacturing

1.1.3. Mechanical behavior

1.1.4. Shaping and welding of thermoplastic composites

1.2. Automatic fiber placement

1.2.1. Co-firing

1.2.2. Dynamic accuracy

1.2.3. Engineering

1.2.4. Maintenance

1.2.5. Optimization

1.2.6. Reduction of the ecological footprint

1.3. Composites and Nanocomposites (including natural fibers, nanoclays , polyhydroxyalkanoates )

1.4. Generation of machining and manufacturing lines

1.5. High-performance removal of materials

1.6. Manufacturing processes , machining, assembly and high performance processing

1.6.1. Additive Manufacturing

1.6.2. Generation of machining lines / manufacturing

1.6.3. High-performance removal of materials

1.6.4. Surface treatment

1.6.5. welding , shaping

1.7. Plasma surface treatment

1.7.1. Hydrophobization cellulosic surfaces (inert and organic materials)

1.7.2. Hydrophobization of surfaces

1.8. Service behavior

1.8.1. Corrosion

1.8.2. Creep

1.8.3. Fatigue analysis

1.8.4. Residual stresses

1.8.5. Seams and joints

1.8.6. Tribology / Rheology

1.9. Shaping of metal , exotic materials and non-metallic

1.9.1. Hot spinning

1.9.2. Hydroforming

1.9.3. Process simulation (FEM, cellular automata, self- consistent models)

1.10. Stainless steel, porous metals, cellulose nanocrystals , smart materials & polymers

1.10.1. Additive Manufacturing ( polymers , metals , ceramics )

1.10.2. Biodegradable hydrocarbon polymers and biopolymers, cellulose nanocrystals

1.10.3. Porous metals

1.10.4. Smart materials

1.10.4.1. Shape memory alloys

1.10.4.2. Hydrorheologic fluids

1.10.4.3. Magnetorheological fluids

1.10.4.4. Nanomaterials

1.10.5. Stainless steel

1.11. Test, Contrôle & Validation

1.11.1. 3D Metrology & Propagation of uncertainties

1.11.2. Automated Inspection (imaging, vision, artificial intelligence, pattern recognition)

1.11.3. Health monitoring

1.11.4. In-situ inspection

1.11.5. Non-destructive testing standard and non-standard

1.11.6. Normalization

1.11.7. Seals

2. Research units and chairs

2.1. Research chairs

2.1.1. Canada Research Chair in Precision Robotics

2.1.2. Industrial Research Chair in Forming Technologies of High-Strength Alloys

2.2. Certified research units

2.2.1. DYNAMO – Research Laboratory in Machine, Process and Structural Dynamics

2.2.2. GREPCI – Power Electronics and Industrial Control Research Group

2.2.3. LIPPS – Products, Processes and Systems Engineering Laboratory

2.3. Recognized research units

2.3.1. CoRo – Control and Robotics Laboratory

2.3.2. LAMSI – Shape Memory Alloys and Intelligent Systems Laboratory

2.3.3. LFCMC – Composite Materials Manufacturing and Characterization Laboratory

2.3.4. LITP – Production Technologies Integration Laboratory

2.3.5. LOPFA – Optimization of Aerospace Manufacturing Processes Laboratory

2.3.6. NUMERIX – Organizational Engineering Research Laboratory for the Digital Enterprise

3. Sustainable supply chain

3.1. Design and planning of sustainable supply chains

3.2. Green logistics

3.3. Human and environmental impacts

3.4. Manufacturing networks and smart services

3.5. Process reengineering

3.6. Product Lifecycle Management (PLM)

3.7. Simulation and optimization of manufacturing systems

4. New technologies for efficiency in manufacturing

4.1. Advanced Digital tools for design and manufacturing

4.1.1. Highly Productive Digital engineering (4D CAD & Knowledge Management)

4.1.2. Plagiarism Detector for CFAO

4.2. Lean manufacturing

4.2.1. Industrial statistics

4.2.2. Analysis and process optimization

4.2.3. Process optimization

4.2.4. Zero waste

4.3. Modeling & simulation

4.3.1. Inspection systems

4.3.2. Acoustic

4.3.3. Business process

4.3.4. Flows

4.3.5. Manufacturing processes

4.3.6. Multiphysics processes

4.4. Smart systems

4.4.1. Adaptive systems

4.4.2. Artificial intelligence

4.4.3. Artificial neural networks

4.4.4. Evolutionary computation

4.4.5. Learning algorithms

4.4.6. Multiple classifications systems

4.4.7. Pattern recognition

5. High performance robotics

5.1. Control

5.1.1. Control by iterative learning

5.1.2. Parallel positioning systems

5.2. Manufacturing productivity

5.2.1. Design, modeling and analysis of hydraulic & pneumatic systems

5.2.2. In-situ inspection and quality control

5.2.2.1. Non-destructive testing, non-standard and standard

5.2.2.2. Artificial Intelligence

5.2.2.3. 3D metrology

5.2.2.4. Image processing, pattern recognition, artificial vision

5.2.3. Intelligent control of electrical drives and high precision robots

5.2.4. Methods optimization

5.2.5. Predictive maintenance

5.2.6. Process characterization

5.3. Mechatronics and haptic systems

5.3.1. Haptic devices

5.3.2. Physical interaction between humans and robots

5.3.3. Sensor technologies

5.4. Parallel robotics

5.4.1. Development of simulation software

5.4.2. Mechanical design

5.5. Robot dynamic precision

5.5.1. Compensating trajectories

5.5.2. Robot calibration