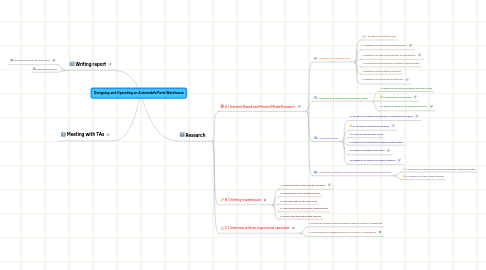

1. Research

1.1. A ) Internet Based and Printed Media Research

1.1.1. 1. Opening a new warehouse/dc

1.1.1.1. 1.1 Research on possible costs

1.1.1.2. 1.2 Research on possible Stocking Systems

1.1.1.3. 1.3 Research on space requirements of a warehouse

1.1.1.4. 1.4 Comparing the profitibility of buying / renting space

1.1.1.5. 1.5 Research various delivery systems

1.1.1.6. 1.6 Research on world class warehouses

1.1.2. 2. Research on a warehouse management system

1.1.2.1. 2.1 Research the existing software and their prices

1.1.2.2. 2.2 Research on employees

1.1.2.3. 2.3 Research feasibility of implementing WMS

1.1.3. 3. Improving Quality

1.1.3.1. 3.1 Research on possible performance measurement systems

1.1.3.2. 3.2 Research on personnel trainings

1.1.3.3. 3.3 Consider doing a work study

1.1.3.4. 3.4 Research on internal and external audit systems

1.1.3.5. 3.5 Research damage return rates

1.1.3.6. 3.6 Research on world-class quality systems

1.1.4. 4. Research on methods to maintain a continuous learning environment

1.1.4.1. 4.1 Research on various self-control mechanisms for the employees

1.1.4.2. 4.2 Research on team-work trainings

1.2. B ) Visiting a warehouse

1.2.1. 1. Collecting data on the company products

1.2.2. 2. Analyzing the used storage systems

1.2.3. 3. Collecting data on the used WMS

1.2.4. 4. Learn about the used quality measurements

1.2.5. 5. Analyze the used automated vehicles

1.3. C ) Interview with an ergonomist specialist

1.3.1. 1. Analyze the possible risks and worker safety concerns in a warehouse

1.3.2. 2. Collecting data on general ergonomic concerns in a warehouse