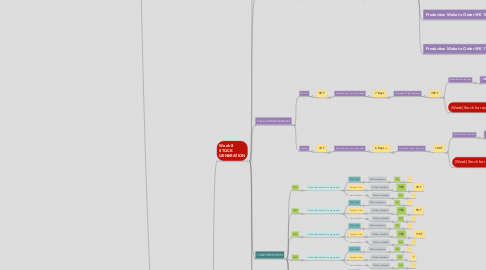

1. STOCK REQUIRED IN PROCESS OUTPUTS

1.1. SEMI FINISHED AREA

1.1.1. Raw Material / Coils

1.1.1.1. 3 DAYS STOCK FOR TUBE FORMER

1.1.1.1.1. 350 T

1.1.2. Formador/Tube former

1.1.2.1. 3 DAYS OF STOCK FOR FURNANCE

1.1.2.1.1. 400 T

1.1.3. Furnace heat treatment,

1.1.3.1. 5 DAYS OF STOCK FOR STRETCHERS

1.1.3.1.1. 350 T

1.1.4. TUBE Drawed

1.1.4.1. WITHOUT STOCK, RUNNING ON LINE

1.1.4.1.1. 70 T

1.1.5. STRAIGHTENERS

1.1.5.1. WITHOUT STOCK, RUNNING ON LINE

1.1.5.1.1. 70 T

1.1.6. Eddy Current

1.1.6.1. WITHOUT STOCK, RUNNING ON LINE

1.1.6.1.1. Minimium production for HAL 1

1.2. CUT AREA

1.2.1. Adiges

1.2.1.1. 2.56 T

1.2.1.1.1. 24,000 Pcs.

1.2.2. RSA

1.2.2.1. .54 T

1.2.2.1.1. 3,000Pcs.

1.2.3. RATTUNDES

1.2.3.1. 38 T

1.2.3.1.1. 90,000 Pcs,

1.2.4. REIKAS

1.2.4.1. 20 T

1.2.4.1.1. Pcs.

1.2.5. HAVEN

1.2.5.1. 5 T

1.2.5.1.1. Pcs.

2. First week (Make to stock programm) HIGH RUNNERS

3. Aproximated Tons (66)

4. Check the client demand to define the stock

5. CAPABILITIES

5.1. CAPABILITIES OF WEEKLY PRODUCTION BY SE PROCESS

5.1.1. Formador

5.1.1.1. Out Put

5.1.1.1.1. Day

5.1.1.1.2. Week

5.1.2. Horno

5.1.2.1. Ripoche

5.1.2.1.1. Out Put

5.1.2.2. Total Output

5.1.2.2.1. 75 T

5.1.2.2.2. Doubles steps

5.1.2.3. Can Eng

5.1.2.3.1. Out Put

5.1.3. Drawing Processes

5.1.3.1. 1051

5.1.3.1.1. Out Put

5.1.3.1.2. Weekly

5.1.3.2. 2052

5.1.3.2.1. Out Put

5.1.3.3. 2053

5.1.3.3.1. Out Put

5.1.3.4. Total Out Put

5.1.3.4.1. 92 T

5.1.3.4.2. Doubles steps

5.1.3.5. 2054

5.1.3.5.1. Out Put

5.1.3.5.2. Weekly Out put

5.1.3.6. 3055

5.1.3.6.1. Out Put

5.1.3.7. 3056

5.1.3.7.1. Out Put

5.1.4. STRAIGHTENERS

5.1.4.1. 2061

5.1.4.1.1. Out Put

5.1.4.2. Total Out Put

5.1.4.2.1. 60T

5.1.4.3. 2062

5.1.4.3.1. Out Put

5.1.5. Eddy Current

5.1.5.1. 2081

5.1.5.1.1. Out Put

5.1.5.2. Total Out Put

5.1.5.2.1. 60 T

5.1.5.3. 2082

5.1.5.3.1. Out Put

5.2. CAPABILITIES OF DAILY PRODUCTION BY CUT PROCESS

5.2.1. Adige1

5.2.1.1. Daily Out Put

5.2.1.1.1. 3 T

5.2.1.2. Weekly Output

5.2.1.2.1. 6.72 T

5.2.2. Adige2

5.2.2.1. Out Put

5.2.2.1.1. 1.6 T

5.2.2.2. Weekly Output

5.2.2.2.1. 6.72 T

5.2.3. RSA

5.2.3.1. Out Put

5.2.3.1.1. 3 T

5.2.4. Rattunde1

5.2.4.1. Out Put

5.2.4.1.1. 12 T

5.2.5. Rattunde2

5.2.5.1. Out Put

5.2.5.1.1. 12 T

5.2.6. TOTAL Output

5.2.6.1. 60 T

5.2.7. Rattunde3

5.2.7.1. Out Put

5.2.7.1.1. 12 T

5.2.8. Rattunde 4

5.2.8.1. Out Put

5.2.8.1.1. 12 T

5.2.9. Reika 2093

5.2.9.1. Out Put

5.2.9.1.1. 10 T

5.2.10. Reika 2094

5.2.10.1. Out Put

5.2.10.1.1. 10 T

5.3. Definition of weeks to be programed

6. Programming Weekly of process outputs

6.1. Week 8 STOCK GENERATION

6.1.1. Daily Minimium Stock of Raw Material Requiered for the Week (3 days stock)

6.1.1.1. 240 T

6.1.2. Daily Tube Former Output

6.1.2.1. 80 T

6.1.2.1.1. Number of operation days at Week

6.1.3. Furnance Heat Treatment

6.1.3.1. Ripoche

6.1.3.1.1. 50 T

6.1.3.2. CanEng

6.1.3.2.1. 18 T

6.1.4. TUBE STRETCHERS

6.1.4.1. 1051

6.1.4.1.1. Kind of tube that can be programed

6.1.4.2. 2052

6.1.4.2.1. Kind of tube that can be programed

6.1.4.3. 2053

6.1.4.3.1. Kind of tube that can be programed

6.1.4.4. 2054

6.1.4.4.1. Kind of tube that can be programed

6.1.4.5. 3055

6.1.4.5.1. Kind of tube that can be programed

6.1.4.6. 3056

6.1.4.6.1. Kind of tube that can be programed

6.1.4.7. 385 T_Total Week Output

6.1.4.7.1. .

6.1.5. STRAIGHTENERS

6.1.5.1. 2061

6.1.5.1.1. 22.5 T

6.1.5.2. 2062

6.1.5.3. 315 T_Total Week Output

6.1.5.3.1. STOCK 70 T

6.1.6. Eddy Current

6.1.6.1. 2081

6.1.6.1.1. 22.5 T

6.1.6.2. 2082

6.1.6.2.1. 22.5 T

6.1.6.3. 315 T_Total Week Output

6.2. Week 2 Keeping stock and cover client demands

6.2.1. Daily Minimium Stock of Raw Material Requiered for the Week (3 days stock)

6.2.1.1. 240 T

6.2.2. Daily Tube Former Output

6.2.2.1. 80 T

6.2.2.1.1. 22.5 T

6.2.2.1.2. Number of operation days at Week

6.2.3. Furnance Heat Treatment

6.2.3.1. Ropoche

6.2.3.1.1. 50 T

6.2.3.2. CanEng

6.2.3.2.1. 30 T

6.2.4. TUBE STRETCHERS

6.2.4.1. 1051

6.2.4.1.1. Kind of tube that can be programed

6.2.4.2. 2052

6.2.4.2.1. Kind of tube that can be programed

6.2.4.3. 2053

6.2.4.3.1. Kind of tube that can be programed

6.2.4.4. 2054

6.2.4.4.1. Kind of tube that can be programed

6.2.4.5. 3055

6.2.4.5.1. Kind of tube that can be programed

6.2.4.6. 3056

6.2.4.6.1. Kind of tube that can be programed

6.2.4.7. 276 T_Total Week Output

6.2.5. STRAIGHTENERS

6.2.5.1. 2061

6.2.5.1.1. 22.5 T

6.2.5.2. 2062

6.2.5.2.1. 22.5 T

6.2.5.3. 270 T_Total Week Output

6.2.6. Eddy Current

6.2.6.1. 2081

6.2.6.1.1. 22.5 T

6.2.6.2. 2082

6.2.6.2.1. 22.5 T

6.2.6.3. 270 T_Total Week Output

6.3. Week 3

6.3.1. Daily Stock of Raw Material Requiered for the Week

6.3.1.1. Tons

6.3.2. Daily Tube former output

6.3.2.1. T

6.4. Week 4

6.4.1. Daily Stoks of Raw Material Requiered for the Week

6.4.1.1. Tons

6.4.2. Daily Tube Former Output

6.4.2.1. T

6.5. Week 5

6.5.1. Daily Stock or Raw Material Requiered for the Week

6.5.1.1. Tons

6.5.2. Daily Tube Former Output

6.5.2.1. T

6.6. Week 6

6.6.1. Daily Stock of Raw Material Requiered for the Week

6.6.1.1. Tons

6.6.2. Daily Tube Former Output

6.6.2.1. T

6.6.2.1.1. Number of operation days at week

7. DEMAND CLIENTS VS. CAPABILITIES (Output)

7.1. WEEK 8

7.1.1. Wk 10_Production Plan

7.1.1.1. Clients Demand

7.1.1.1.1. 312 T

7.1.1.2. Weekly Capability

7.1.1.2.1. 315 Tons

7.2. WEEK 9

7.2.1. Wk 11_Production Plan

7.2.1.1. Clients Demand

7.2.1.1.1. 362 T

7.2.1.2. Weekly Capability

7.2.1.2.1. 315 Tons

7.3. WEEK 10

7.3.1. Wk 12_Production Plan

7.3.1.1. Clients Demand

7.3.1.1.1. 442 T

7.3.1.2. Weekly Capability

7.3.1.2.1. 315 Tons

7.4. WEEK 11

7.4.1. Wk 13_Production Plan

7.4.1.1. Clients Demand

7.4.1.1.1. 384 T

7.4.1.2. Weekly Capability

7.4.1.2.1. 315 Tons

7.5. WEEK 12

7.5.1. Wk 14_Production Plan

7.5.1.1. Clients Demand

7.5.1.1.1. 296 T

7.5.1.2. Weekly Capability

7.5.1.2.1. 315 Tons

7.6. WEEK 13

7.6.1. Wk 15_Production Plan

7.6.1.1. Clients Demand

7.6.1.1.1. 379 T

7.6.1.2. Weekly Capability

7.6.1.2.1. 423.9 Tons

8. Shall be based on client Demand

9. Increase of draw machines in the Semifinished processes

9.1. Drawing Processes

9.1.1. 1051

9.1.1.1. Out Put

9.1.1.1.1. 6 T

9.1.1.2. Weekly

9.1.1.2.1. 42 T

9.1.2. 2052

9.1.2.1. Out Put

9.1.2.1.1. 20 T

9.1.3. 2053

9.1.3.1. Out Put

9.1.3.1.1. 30T

9.1.4. Total Out Put

9.1.4.1. 92 T

9.1.4.2. Doubles steps

9.1.4.2.1. T

9.1.5. 2054

9.1.5.1. Out Put

9.1.5.1.1. 6 T

9.1.5.2. Weekly Out put

9.1.5.2.1. 42 T

9.1.6. 3055

9.1.6.1. Out Put

9.1.6.1.1. 12 T

9.1.7. 3056

9.1.7.1. Out Put

9.1.7.1.1. 18 T