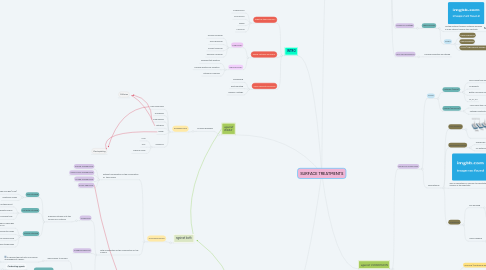

1. INTRO

1.1. What do they improve?

1.1.1. CORROSION

1.1.2. OXIDATION

1.1.3. WEAR

1.1.4. FATIGUE

1.2. Which methods are used?

1.2.1. CHEMICAL

1.2.1.1. Alcaline cleaning

1.2.1.2. Acid descaling

1.2.1.3. Solvent cleaning

1.2.1.4. Emulsion cleaning

1.2.2. MECHANICAL

1.2.2.1. Abrasive/grit blasting

1.2.2.2. Surface abration by vibration

1.2.2.3. Ultrasonic cleaning

1.3. Some relevant processes

1.3.1. Galvanizing

1.3.2. Electroplating

1.3.3. Organic coatings

2. against WEAR

2.1. increase hardness

2.1.1. POSSIBILITIES

2.1.1.1. Hard Chroming

2.1.1.2. Anodizing

2.1.1.3. Carburazing

2.1.1.4. Nitriding

2.1.1.5. Nickel

2.1.1.6. Ceramics

2.1.1.6.1. CVD

2.1.1.6.2. PVC

2.1.1.6.3. Thermal Spray

3. against FATIGUE

3.1. SHOT PEENING

3.1.1. produce a compressive residual stress layer

4. against both

4.1. CLASSIFICATION

4.1.1. without modification of the composition of the surface

4.1.1.1. FLAME HARDENING

4.1.1.2. INDUCTION HARDENING

4.1.1.3. LASER HARDENING

4.1.1.4. SHOT PEENING

4.1.2. with modification of the composition of the surface

4.1.2.1. NITRIDING

4.1.2.1.1. diffusing nitrogen into the surface of a material

4.1.2.2. CARBONITRIDING

4.1.2.3. CARBURIZING

4.1.2.3.1. adds carbon to surface

4.1.2.3.2. Types

5. Electroplating

6. Diffusion

7. against OXIDATION

7.1. In-situ formation at ↑T of protective oxide layers

7.2. TYPES of COATINGS

7.2.1. DIFFUSION coatings

7.2.1.1. Definition: Deposition of thin metallic coatings at high T

7.2.1.2. CVD (Chemical vapor deposition)

7.2.1.2.1. Interaction between surface of heated substrate and mixture of gases that contain coating elements

7.2.1.2.2. Thermal energy source

7.2.1.2.3. TYPES

7.2.1.3. PVD (Physical vapor deposition)

7.2.1.3.1. Material transformed to vapor phase and condensed on the substrate surface

7.2.1.3.2. Electrical energy source

7.2.1.3.3. Happens in high vacuum

7.2.1.3.4. TYPES

7.2.2. OVERLAY coatings

7.2.2.1. Thermal spray

7.2.2.1.1. Molted metallic/ceramic materials sprayed in a gas stream towards the substrate

7.2.2.1.2. TYPES

7.2.3. ION IMPLANTATION

7.2.3.1. Surface properties are altered

8. against CORROSION

8.1. METALLIC COATINGS

8.1.1. TYPES

8.1.1.1. Cathodic (barrier)

8.1.1.1.1. More-noble than underlying substrate

8.1.1.1.2. No defects

8.1.1.1.3. Better corrosion resistance

8.1.1.1.4. Ni, Cr, Cu

8.1.1.2. Anodic (sacrificial)

8.1.1.2.1. Less-noble than underlying substrate

8.1.1.2.2. Cathodic protection

8.1.2. Deposited by

8.1.2.1. HOT DIPPING

8.1.2.1.1. Process

8.1.2.2. ELECTROPLATING

8.1.2.2.1. Applied by electrolysis

8.1.2.2.2. No external power supply

8.1.2.3. Ions accelerated in a vacuum to penetrate surface of the substrate

8.1.2.4. CLADDING

8.1.2.4.1. Roll bonding

8.1.2.4.2. Laser cladding

8.2. ORGANIC COATINGS

8.2.1. Paints

8.2.1.1. Components

8.2.1.1.1. VEHICLE (continuous phase)

8.2.1.1.2. ADDITIVES

8.2.1.2. Function

8.2.1.2.1. Isolating character

8.2.1.2.2. Corrosion inhibitor

8.2.1.3. Failure

8.2.1.3.1. UV radiation

8.2.1.3.2. Mechanical damage

8.2.1.3.3. Water absorption

8.2.1.3.4. High T

8.2.1.4. Methods of application

8.2.1.4.1. DIP COATING

8.2.1.4.2. FLOW COATING

8.2.1.4.3. ELECTROSTATIC SPRAYING