1. Project Management

1.1. Triple constraints ( scope; cost and time )

1.2. Six constraints ( scope, time, cost, resources, risks, and quality.

2. Quality and Quality Control

2.1. Lean management

2.2. Sourcing and Supply Management

2.3. Make plans before buying things

2.4. The differences between purchasing and Procurement.

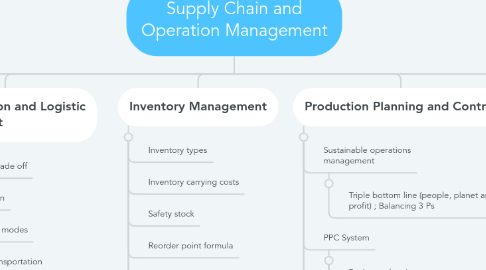

3. Transportation and Logistic Management

3.1. Logistic cost-trade off

3.2. Network design

3.3. Transportation modes

3.4. Intermodal transportation

3.5. Transportation management

3.6. Inventory management

3.7. Warehousing

3.8. Materials handling, packaging and order management.

4. Inventory Management

4.1. Inventory types

4.2. Inventory carrying costs

4.3. Safety stock

4.4. Reorder point formula

4.5. Consignment inventories

4.6. Vendor managed inventory (VMI)

4.7. Inventory technologies

5. Production Planning and Control

5.1. Sustainable operations management

5.1.1. Triple bottom line (people, planet and profit) ; Balancing 3 Ps

5.2. PPC System

5.2.1. Business planning

5.2.2. S & OP

5.2.2.1. Objectives: Helps firms keep demand and supply balance

5.2.3. Capacity Ok? (AP)

5.2.4. MPS

5.2.5. Capacity Ok? (RCCP)

5.2.6. MRP

5.2.7. Capacity Ok? (CRP)

5.2.8. Production Activity Control

5.2.9. Performance

5.3. Production environment

5.4. Purposes of PPC system

6. Process Control and Improvement

6.1. Value stream mapping

6.2. Statistics

6.2.1. Data type

6.2.1.1. Quality and Quantity (variable data, attribute data)

6.2.2. Descriptive statistics:

6.2.2.1. describe a population or complete group of data

6.2.3. Inductive statistics

6.2.3.1. deal with amount of data or a representative sample

6.2.4. Data analysis

6.2.5. Analytical

6.2.5.1. Measure of dispersion

6.3. Variable control chart

6.3.1. Control chart 3 key elements( center line, upper control limit, lower control limit)

6.3.1.1. X bar and R chartts

6.3.1.2. X bar and s charts

6.3.1.3. Chart for individual (x charts)

6.3.2. Attribute data

6.3.2.1. For defective (p-chart, np-chart)

6.3.2.2. For defects (c-chart, u-chart)

6.4. Attribute control Chart

7. Purchasing Management

7.1. Specification and Quality

7.2. Supply Processes

7.2.1. Recognition of need Description of need Identification and analysis of possible sources of supply Supplier selection and determination of terms Preparation and placement of the purchase order Follow-up and/or expedite the order Receipt and inspection of goods Invoice clearing and payment Maintenance of records and relationships