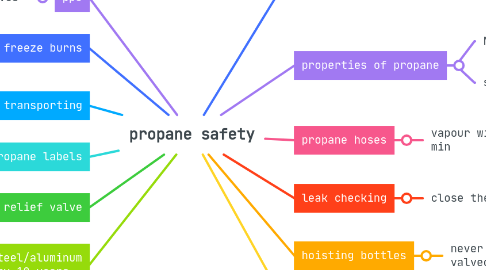

1. ppe

1.1. when filling use neoprene gloves

2. freeze burns

2.1. if liquid prpane touches the skin it will cause a freeze burn

2.1.1. treat with luke warm water

3. transporting

3.1. max 5 bottles in a vehi cle or 1100lbs

3.1.1. must be transported up right and secured

3.1.1.1. labels must be facing outside of the truck

4. propane labels

4.1. whimis

4.1.1. tmg

5. safety relief valve

5.1. all cylinders have a safetey reief valve to realease at 375psi

6. recertified steel/aluminum clyinders every 10 years

6.1. recertify composite cylinders every 5 years

7. types of propane

7.1. liquid withdrawel

7.1.1. uses dip tube to withdraw from bottom of nthe tank

7.1.1.1. uses external left hand male thread

7.1.1.1.1. uses excess flow preventer

7.2. vapour withdrwawel

7.2.1. internal left hand female thread

7.2.1.1. connected regulators have aexternal left hand male thread

8. properties of propane

8.1. Next level topic

8.2. stored as a liquid

8.2.1. boiling point -42c or -44f

8.2.1.1. expansion rate 0f 1:270

8.2.1.1.1. requires ambient heat to change state

9. propane hoses

9.1. vapour withdrawel rated for 125psi min

9.1.1. liquid withdrawel rated for 350psi min

10. leak checking

10.1. close the torch valve

10.1.1. slowly open the cylinder valve

10.1.1.1. use soapy water to all connections

10.1.1.1.1. look for bubbles

11. hoisting bottles

11.1. never hoist bootles by the cylinder valveor protective collar

11.1.1. use a lifting cage or other device designed for lifting

12. overflow protection device

12.1. some propane clyinder valves have an opd that prevnts filing the tank beyond 80% of its compacity

12.1.1. it is illegalto fill past 80%

12.1.1.1. tanks with an opd have a triangle shaped handle

12.1.1.1.1. propane cylinders with a roundhand wheel dont have the safety device