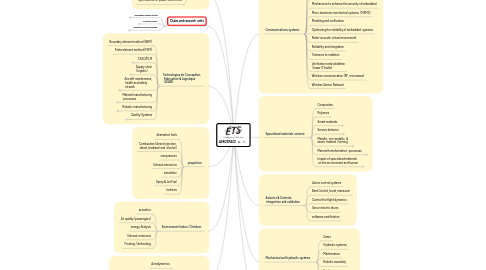

1. Energy

1.1. Autonomy in flight, minimization of consumption

1.2. Fuel cells

1.3. Optimization of power electronics

2. Chairs and research units

2.1. Accredited research units

2.1.1. DYNAMO – Research Laboratory in Machine, Process and Structural Dynamics

2.1.2. LIPPS – Products, Processes and Systems Engineering Laboratory

2.2. Research chairs

2.2.1. Canada Research Chair for Aircraft Modeling and Simulation Technologies

2.2.2. NSERC/P&WC Industrial Research Chair on Propulsion System Integration and Optimization

2.3. Research units recognized

2.3.1. ACEFE – Stress Analysis by Finite Element and Testing Laboratory

2.3.2. C2SP – Design and Control of Production Systems Laboratory

2.3.3. LAMSI – Shape Memory Alloys and Intelligent Systems Laboratory

2.3.4. LARCASE – Aeronautical Research Laboratory in Active Control, Avionics and Aeroservoelasticity

2.3.5. TFT – Thermo-Fluids for Transport Laboratory

3. Technologies de Conception, Fabrication & Logistique (LEAN)

3.1. Boundary element method (BEM)

3.2. Finite element method (FEM)

3.3. CFAO/PLM

3.3.1. Computer-aided design (CAD)

3.3.2. Computer Aided Manufacturing (FAO)

3.3.3. Life cycle management of products (PLM)

3.4. Supply chain (logistic)

3.4.1. Analysis, planning, scheduling and optimization of the supply chain

3.4.2. Design and planning of sustainable supply chains

3.4.3. Green logistics

3.4.4. Management and inventory optimization

3.4.5. Manufacturing networks and smart services

3.4.6. Operations Research

3.4.7. Optimization of transport flows

3.4.8. process analysis and optimization

3.4.9. Production / Operations management (MRP SAP, etc ...)

3.4.10. Remanufacturing

3.4.11. RFID technology

3.4.11.1. Identification

3.4.11.2. Security

3.4.11.3. Traceability

3.4.12. Simulation and optimization of manufacturing systems

3.5. Aircraft maintenance, health and safety at work

3.5.1. Ergonomics and Industrial Hygiene

3.5.1.1. Air quality, contaminant dispersion, energy exchange, ventilation (field study, experimental and numerical models)

3.5.1.2. Biometrological predictive index

3.5.1.3. Industrial Acoustics (control and prevention of deafness)

3.5.1.4. Physical ergonomics (prevention of musculoskeletal injuries)

3.5.2. Integrated Risk Management of Health and Safety (modeling and field)

3.5.3. Security at work

3.5.3.1. Design, testing and standardization of protective equipment (working at heights and hearing protection)

3.5.3.2. Fire protection

3.5.3.3. Maintenance (lockout)

3.5.3.4. Safety equipment, machinery and structures (safe design)

3.5.3.5. Sealing and pressure vessels

3.6. Material manufacturing processes

3.6.1. Generating machining scales

3.6.2. Formatting metallic and nonmetallic materials

3.6.3. Additive Manufacturing

3.6.4. welding

3.6.5. Thermal treatments (including induction)

3.6.6. High-performance machining

3.6.7. Machining of new materials, and exotic composites

3.7. Robotic manufacturing

3.7.1. Artificial Intelligence

3.7.2. Design, modeling and analysis of hydraulic & pneumatic systems

3.7.3. Image processing, pattern recognition, artificial vision

3.7.4. Intelligent control of electrical drives and high precision robots

3.8. Quality Systems

3.8.1. Management

3.8.1.1. Continuous improvement

3.8.1.2. Control ranges

3.8.1.3. Industrial statistics

3.8.1.4. Internal Audit ISO-9000

3.8.1.5. Lean management

3.8.1.6. Multidisciplinary optimization

3.8.1.7. Process optimization

3.8.1.8. Quality standards & standardization

3.8.1.9. Software maintenance

3.8.1.10. Technical problem solving

3.8.2. Measures

3.8.2.1. 3D Metrology & uncertainties propagation

3.8.2.2. Automated inspection (imaging, vision, artificial intelligence, pattern recognition)

3.8.2.3. Inspection of pieces (scan, manufacturing tolerances)

3.8.2.4. Non-destructive testing standard and non-standard

4. propulsion

4.1. alternative fuels

4.2. Combustion (direct injection, diesel, biodiesel and alcohol)

4.3. compressors

4.4. Exhaust emissions

4.5. simulation

4.6. Spray & Jet Fuel

4.7. turbines

5. Environment Indoor / Outdoor

5.1. acoustics

5.2. Air quality (passengers)

5.3. energy Analysis

5.4. Exhaust emissions

5.5. Frosting / defrosting

6. Science of flight

6.1. Aerodynamics

6.2. aeroelasticity

6.3. Fluid dynamics (experimental, numerical)

6.4. Mechanical and performance of the flight

7. Communications systems

7.1. Antennas

7.2. Communication / Navigation Satellite System (GNSS)

7.3. Electronics for satellite design

7.4. Mechanisms to enhance the security of embedded

7.5. Micro electronic mechanical systems (MEMS)

7.6. Modeling and verification

7.7. Optimizing the reliability of embedded systems

7.8. Radio-acoustic virtual environment

7.9. Reliability and integration

7.10. Tolerance to radiation

7.11. Verification and validation (lower IT faults)

7.12. Wireless communication (RF, microwave)

7.13. Wireless Sensor Network

8. Specialised materials science

8.1. Composites

8.2. Polymers

8.3. Smart materials

8.3.1. Hydro rheological fluid

8.3.2. Magnetorheological fluids

8.3.3. Nanomaterials

8.3.4. Shape memory alloys

8.4. Service behavior

8.4.1. Fatigue Analysis

8.4.2. Corrosion

8.4.3. Creep

8.4.4. Residual stresses

8.4.5. Seams and joints

8.4.6. Rheology

8.5. Metallic, non-metallic & exotic material forming

8.5.1. Hot spinning

8.5.2. Hydroforming

8.5.3. Process simulation (FEM, cellular automata, self-consistent models)

8.6. Material transformation processes

8.6.1. Additive Manufacturing

8.6.2. Brazing

8.6.3. Contour hardening

8.6.4. Generation of machining lines / manufacturing

8.6.5. High-performance removal of materials

8.6.6. Surface treatment

8.6.7. Welding

8.7. Impact of specialized materials on the environment and human

8.7.1. Analysis of sources of air pollution for workers

8.7.2. Industrial waste management

8.7.3. Nanotoxicology

8.7.4. Treatment of industrial effluents

8.7.5. Clean machining

9. Avionics & Controls, integration and validation

9.1. Active control systems

9.2. Beat Control, burst, maneuver

9.3. Control the flight dynamics

9.4. Servo-electric drives

9.5. software certification

10. Mechanical and hydraulic systems

10.1. Gears

10.2. Hydraulic systems

10.3. Maintenance

10.4. Robotic assembly

10.5. Sealing

10.6. Vibration & diagnostics

11. Researchers and departments involved

11.1. Departments

11.1.1. Department of Automated Production

11.1.2. Department of construction

11.1.3. Department of Electrical

11.1.4. Department of Mechanical

11.1.5. Department of Software and IT

11.2. Researchers

11.2.1. Number of researchers "Core": 20 (researchers who have this area as a central research theme)

11.2.2. Number of researchers "No Core": 26 (researchers who participate in research projects may be related to this topic)