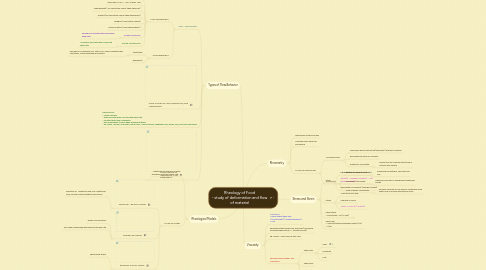

1. Types of Flow Behavior

1.1. NON - NEWTONIAN

1.1.1. TIME INDEPENDENT

1.1.1.1. viscosity depend on shear rate BUT independent of shearing time

1.1.1.2. "APPARENT VISC." - visc. at spec. rate

1.1.1.3. Pseudoplastic ( no yield stress rquire/ shear thinning )

1.1.1.4. Dilatant (no yield stress rquire/ shear thickening )

1.1.1.5. Bingham ( yield stress require)

1.1.1.6. Casson Plastics ( yield stressrequire )

1.1.1.7. SHEAR THINNING

1.1.1.7.1. DECREASE viscosity with INCREASE shear rate

1.1.1.8. SHEAR THICKENING

1.1.1.8.1. INCREASE viscosity with INCREASE shear rate

1.1.2. TIME DEPENDENT

1.1.2.1. Thixotropic

1.1.2.1.1. DECREASE in apparent visc. with TIME under constant shear rate/stress, follow with gradual recovery

1.1.2.2. Rheopectic

1.2. FLOW CURVES OF NON-NEWTONIAN,TIME INDEPENDENT

1.3. NEWTONIAN - usually solution - shear viscosity does not vary with shear rate - constant with time of shearing - falls immediately to zero when shearing stopped - eg : water, mineral, liq lecithin, prune conc., various syrups, vegetables oils, honey, milk, fruit juices and wine

1.4. FLOW CURVES OF NEWTONIAN, TIME DEPENDENT

2. Rheological Models

2.1. - mathematical epressions relate the shear stress and shear rate

2.2. TYPES OF MODEL

2.2.1. HERSCHEL - BULKLEY MODEL

2.2.1.1. indication of Newtonian and Non-Newtonian flow, provide material without yield stress

2.2.2. POWER LAW MODEL

2.2.2.1. shows no yield stress

2.2.2.2. non-linear relationship with shear stress and rate

2.2.3. BINGHAM PLASTIC MODEL

2.2.3.1. shows yield stress

3. Stress and Strain

3.1. Strain

3.1.1. a quantitative measure to an extent

3.1.2. Strain(Ɛ) = Change in length (L - Lo) / Original length (L)

3.1.3. defromation of element (change in shape)

3.2. Stress

3.2.1. a force per unit area

3.2.2. intensity of force

3.2.3. Stress = Force (F) / Area (A)

3.3. Shear stress = Force/Area = Pa (SI Unit)

3.3.1. h

3.4. Shear rate = Velocity/Distance between plates (V/x) = 1/sec

4. Viscosity

4.1. VISCOSITY = shear stress/shear rate = (Force/Area) / (Velocity/Distance) = Pa.s

4.2. parameters that shows fluid flow prop (according to applied shear stress <> resistance flow)

4.3. eg : honey - more viscous than milk

4.4. FACTOR THAT AFFECT ON VISCOSITY

4.4.1. Shear rate

4.4.1.1. High

4.4.1.2. Moderate

4.4.1.3. Low

4.4.2. Shear time

4.4.3. Temperature

4.4.4. Pressure

5. Rheometry

5.1. approaches to test and see

5.2. immitate some aspect of processing

5.3. TYPES OF RHEOMETRY

5.3.1. FUNDAMENTAL

5.3.1.1. using well-define test fixture (geometry) and test condition

5.3.1.2. gives absolute value of viscosity

5.3.1.3. Rotational Viscometer

5.3.1.3.1. involve the use of known test fiture in contact with sample

5.3.2. EMPIRICAL

5.3.2.1. Bostwick Consistometer

5.3.2.1.1. measuring consistency, flow rate and visc.

5.3.2.2. Falling Ball Viscometer

5.3.2.2.1. measures viscosity of transparent Newtonian liquids

5.3.2.3. Glass Capillary Viscometer

5.3.2.3.1. measure viscosity of low viscous Newtonian food under flow of normal gravitational force