1. FRAMEWORK

1.1. SAP

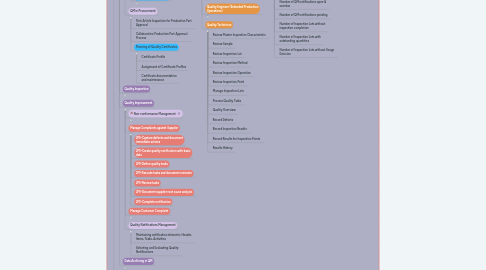

1.1.1. Quality Planning

1.1.1.1. Inspection Planning / Inspection Plans

1.1.1.1.1. Manage Inspection Plans

1.1.1.2. QM in Procurement

1.1.1.2.1. First Article Inspection for Production Part Approval

1.1.1.2.2. Collaborative Production Part Approval Process

1.1.1.2.3. Planning of Quality Certificates

1.1.2. Quality Inspection

1.1.2.1. Control Charts

1.1.2.1.1. Manage Control Charts

1.1.2.1.2. Maintaining Master Inspection Characteristics for Control Charts

1.1.2.2. Inspection Completion

1.1.2.2.1. Manage Usage Decisions

1.1.2.2.2. Making a Usage Decision

1.1.2.2.3. Automate Usage Decision

1.1.2.3. Inspection Lot Creation in Logistical Processes

1.1.2.3.1. Inspections for Goods Movements

1.1.2.3.2. Inspection for a Delivery

1.1.2.3.3. Recurring Inspections of Batches

1.1.2.3.4. Managing Serial Numbers in QM

1.1.2.3.5. Creating an Inspection Lot Manually

1.1.2.3.6. Process Inspection Lots for Production Versions

1.1.2.4. Inspection Lot Creation in Procurement

1.1.2.4.1. 1FM-Review Purchased material notification

1.1.2.4.2. 1FM-Review quality info record

1.1.2.4.3. 1FM-Review inspection plan and sampling scheme

1.1.2.4.4. 1FM-Release goods for receipt

1.1.2.4.5. 1FM-Display open inspection lots

1.1.2.4.6. 1FM-Record inspection results

1.1.2.4.7. 1FM-Make usage decision

1.1.2.4.8. 1FM-Review and analyze defects

1.1.2.4.9. 2F9-Create quality notification with basic data

1.1.2.5. Manage Inspection Lots

1.1.2.5.1. Display Inspection Lot

1.1.2.5.2. Display Inspection Operation

1.1.2.5.3. Change Inspection Lot

1.1.2.5.4. Calculation of the Sample Size

1.1.2.5.5. Resetting Sample Determination

1.1.2.5.6. Corrections to Inspection Lot Quantities

1.1.2.5.7. Sample-Drawing Instruction

1.1.2.6. Quality Inspection for Goods Receipt from Production

1.1.2.6.1. 1E1-Review Produced item

1.1.2.6.2. 1E1-Display inspection plan

1.1.2.6.3. 1E1-Display inspection lot

1.1.2.6.4. 1E1-Record inspection results

1.1.2.6.5. 1E1-Make usage decision

1.1.2.6.6. 1E1-Review and analyze defects

1.1.2.7. Quality Inspection Within the Production Process

1.1.2.7.1. 1E1-Review production order / plan

1.1.2.7.2. 1E1-Display routing including quality operation

1.1.2.7.3. 1E1-Display inspection lot

1.1.2.7.4. 1E1-Update and Analyze control charts

1.1.2.7.5. 1E1-Record inspection results

1.1.2.7.6. 1E1-Review and analyze defects

1.1.2.7.7. 1E1-Confirm the quality operation of the production order

1.1.2.7.8. 1E1-Make usage decision

1.1.2.8. Quality Certificates

1.1.2.8.1. Manage Certificate Receipts

1.1.2.8.2. Quality Certificates for Inspection Lots

1.1.2.8.3. Quality Certificates for Batches

1.1.2.9. Quality Levels Identification

1.1.2.9.1. Manage Quality Levels

1.1.2.9.2. Deletion of Quality Levels

1.1.2.10. Results Recording

1.1.2.10.1. Record Inspection Results

1.1.2.10.2. Record Results for Inspection Points

1.1.2.10.3. Valuation Modes for Sampling Procedures

1.1.2.11. Worklist

1.1.2.11.1. Define types of Variants for Worklists

1.1.3. Quality Improvement

1.1.3.1. Non-conformance Management

1.1.3.1.1. Defects Recording

1.1.3.1.2. Problem Solving

1.1.3.1.3. Quality Tasks

1.1.3.1.4. Internal Nonconformities (NCRs)

1.1.3.2. Manage Complaints against Supplier

1.1.3.2.1. 2F9-Capture defects and document immediate actions

1.1.3.2.2. 2F9-Create quality notification with basic data

1.1.3.2.3. 2F9-Define quality tasks

1.1.3.2.4. 2F9-Execute tasks and document outcome

1.1.3.2.5. 2F9-Review tasks

1.1.3.2.6. 2F9-Document supplier root cause analysis

1.1.3.2.7. 2F9-Complete notification

1.1.3.3. Manage Customer Complaint

1.1.3.3.1. 2FA-Create quality notification with basic data

1.1.3.3.2. 2FA-Capture defects, define root cause analysis, and document immediate actions

1.1.3.3.3. 2FA-Define corrective actions and correction tasks

1.1.3.3.4. 2FA-Execute root cause analysis, corrective actions, correction tasks, and document outcome

1.1.3.3.5. 2FA-Review outcome against desired requirement and define correction tasks

1.1.3.3.6. 2FA-Define preventive actions

1.1.3.3.7. 2FA-Execute preventive actions and document outcome

1.1.3.3.8. 2FA-Monitor preventive actions outcome

1.1.3.3.9. 2FA-Complete quality notification

1.1.3.4. Quality Notifications Management

1.1.3.4.1. Maintaining notification elements: Header, Items, Tasks, Activities

1.1.3.4.2. Selecting and Evaluating Quality Notifications

1.1.4. Data Archiving in QM

1.1.4.1. Archiving Master Data

1.1.4.2. Archiving Inspection Plans

1.1.4.3. Archiving Inspection Lots

1.1.4.4. Archiving Quality Info Records in Procurement

1.1.4.5. Archiving Quality Notifications (QM-QN)

1.1.4.6. Archiving Quality Certificates

1.1.4.7. Archiving Quality Tasks

1.1.4.8. Business Partner End of Purpose (EoP) Check for Inspection Lots

1.1.4.9. Business Partner End of Purpose (EoP) Check for Quality Notifications

1.1.4.10. Business Partner End of Purpose (EoP) Check for Quality Tasks

1.1.4.11. Business Partner End of Purpose (EoP) Check for Problem-Solving Processes

1.2. APQC

1.2.1. Manage enterprise quality

1.2.1.1. Determine quality requirements

1.2.1.1.1. Define critical-to-quality characteristics

1.2.1.1.2. Define preventive quality activities

1.2.1.1.3. Develop quality controls

1.2.1.1.4. Finalize quality plan

1.2.1.1.5. Prove internal capability

1.2.1.2. Evaluate performance to requirements

1.2.1.2.1. Tests against the quality plan

1.2.1.2.2. Assess the results of these tests

1.2.1.3. Manage non-conformance

1.2.1.3.1. Assess potential impact

1.2.1.3.2. Determine immediate action(s)

1.2.1.3.3. Identify root cause(s)

1.2.1.3.4. Take corrective or preventative action

1.2.1.3.5. Close non-conformance

1.2.1.4. Implement and maintain the enterprise quality management system (EQMS)

1.2.1.4.1. Define the quality strategy

1.2.1.4.2. Plan and deploy the EQMS scope, targets, and goals

1.2.1.4.3. Identify core EQMS processes, controls, and metrics

1.2.1.4.4. Develop and document EQMS policies, procedures, standards, and measures

1.2.1.4.5. Assess the EQMS performance

1.2.1.4.6. Create environment and capability for EQMS improvement(s)

1.2.2. Develop, Manage, and Deliver Analytics

1.2.2.1. Collect quality data

1.2.2.2. Analyze quality data

1.2.2.3. Review and purplish quality performance

1.2.2.4. Identify remedial actions

2. ROLES

2.1. Quality Manager

2.1.1. Inspection Lot Analytics

2.1.2. Inspection Lot Detailed Analytics

2.2. Quality Planner

2.2.1. Review Quality Info Record for Procurement

2.2.2. Review Sampling Procedure

2.2.3. Manage Inspection Plans

2.3. Quality Engineer

2.3.1. Characteristic Analytics

2.3.2. Characteristic Detailed Analytics

2.3.3. Manage Control Charts

2.3.4. Manage Defects

2.3.5. Manage Quality Info Records

2.3.6. Manage Quality Levels

2.3.7. Manage Quality Tasks

2.3.8. Manage Usage Decisions

2.3.9. Non conformance Analytics

2.3.10. Quality Overview

2.3.11. Quality Level History

2.3.12. Resolve Internal Problems

2.4. Quality Engineer (Extended Production Operations)

2.4.1. Product Genealogy

2.4.2. Production Action Log

2.5. Quality Technician

2.5.1. Review Master Inspection Characteristic

2.5.2. Review Sample

2.5.3. Review Inspection Lot

2.5.4. Review Inspection Method

2.5.5. Review Inspection Operation

2.5.6. Review Inspection Point

2.5.7. Manage Inspection Lots

2.5.8. Process Quality Tasks

2.5.9. Quality Overview

2.5.10. Record Defects

2.5.11. Record Inspection Results

2.5.12. Record Results for Inspection Points

2.5.13. Results History