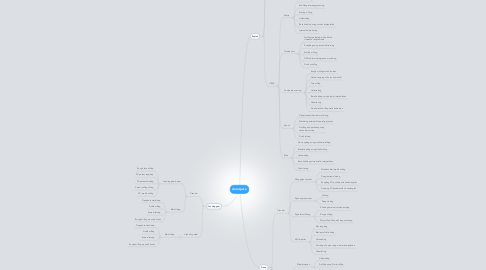

1. Landing gear

1.1. Titanium

1.1.1. Landing gear beam

1.1.1.1. Rough face milling

1.1.1.2. 2D pocket roughing

1.1.1.3. 2D pocket finishing

1.1.1.4. Corner milling slicing

1.1.1.5. 2D profile milling

1.1.2. Main fitting

1.1.2.1. Deep hole machining

1.1.2.2. Profile milling

1.1.2.3. Internal turning

1.1.2.4. Rough milling around bosses

1.2. High alloy steel

1.2.1. Main fitting

1.2.1.1. Deep hole machining

1.2.1.2. Profile milling

1.2.1.3. Internal turning

1.2.1.4. Rough milling around bosses

2. Engine

2.1. Titanium

2.1.1. Fan disc

2.1.1.1. Boring of deep internal chambers

2.1.1.2. Milling of large tulip slots

2.1.1.3. Machining of difficult-to-access grooves

2.1.2. Fan casing

2.1.2.1. External and internal turning

2.1.3. Blisk

2.1.3.1. Full slot rough milling

2.1.3.2. Blade finishing using flank milling

2.1.3.3. Holemaking

2.1.3.4. Bore finishing using circular interpolation

2.1.3.5. Chamfering

2.2. High alloy steel

2.2.1. Shafts

2.2.1.1. Internal boring

2.2.1.2. End flange turning/grooving

2.2.1.3. Scallop milling

2.2.1.4. Holemaking

2.2.1.5. Bore finishing using circular interpolation

2.2.1.6. Internal bottle boring

2.3. HRSA

2.3.1. Shafts

2.3.1.1. Internal boring

2.3.1.2. End flange turning/grooving

2.3.1.3. Scallop milling

2.3.1.4. Holemaking

2.3.1.5. Bore finishing using circular interpolation

2.3.1.6. Internal bottle boring

2.3.2. Turbine disc

2.3.2.1. Profiling/pocketing with difficult clearance requirements

2.3.2.2. Roughing using trochoidal turning

2.3.2.3. Scallop milling

2.3.2.4. Difficult-to-access groove machining

2.3.2.5. Finish profiling

2.3.3. Combustion casing

2.3.3.1. Rough milling around bosses

2.3.3.2. Helical ramping of holes from solid

2.3.3.3. Turn-milling

2.3.3.4. Holemaking

2.3.3.5. Bore finishing using circular interpolation

2.3.3.6. Chamfering

2.3.3.7. Finish profile milling walls and bores

2.3.4. Spool

2.3.4.1. Deep internal chamber machining

2.3.4.2. Machining external blade tulip grooves

2.3.4.3. Profiling and pocketing using trochoidal turning

2.3.4.4. Finish turning

2.3.5. Blisk

2.3.5.1. Slot roughing using trochoidal milling

2.3.5.2. Blade finishing using flank milling

2.3.5.3. Holemaking

2.3.5.4. Bore finishing using circular interpolation

2.3.5.5. Chamfering

3. Frame

3.1. Titanium

3.1.1. Wing pylon bracket

3.1.1.1. Slot/shoulder/profile milling

3.1.1.2. Deep/narrow slotting

3.1.1.3. Roughing 3D pockets with closed angles

3.1.1.4. Finishing 3D pockets with closed angles

3.1.2. Pylon engine mount

3.1.2.1. Drilling

3.1.2.2. Deep slotting

3.1.3. Pylon thrust fitting

3.1.3.1. Finishing external circular ramping

3.1.3.2. Plunge milling

3.1.3.3. 2D profile milling with long overhang

3.1.4. APU impeller

3.1.4.1. Slot roughing

3.1.4.2. Blade profile finishing

3.1.4.3. Holemaking

3.1.4.4. Finishing of bores using circular interpolation

3.1.4.5. Chamfering

3.2. Composite

3.2.1. Wing/wingbox

3.2.1.1. Holemaking

3.2.1.2. Profiling using Sturtz milling

3.2.1.3. Surface machining

3.2.2. Fuselage central wing box

3.2.2.1. Holemaking in CFRP/Ti stack

3.2.2.2. Holemaking in CFRP/Al stack

3.2.3. Vertical tail

3.2.3.1. Holemaking

3.2.3.2. Edging

3.3. Aluminium

3.3.1. Wing rib

3.3.1.1. Thin wall machining

3.3.1.2. Corner milling - slicing

3.3.1.3. Roughing of 2D pockets

3.4. High alloy steel

3.4.1. Slat track

3.4.1.1. 2D pocket milling

3.4.1.2. Face milling

3.4.1.3. Slotting

3.4.1.4. 2D profile milling

3.5. Stainless steel

3.5.1. Flap track

3.5.1.1. 2D pocket milling

3.5.1.2. Face milling

3.5.1.3. Slotting

3.5.1.4. 2D profile milling