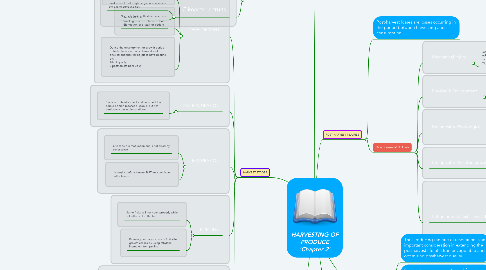

1. Classification Of Fruits

1.1. Non-climacteric fruits

1.1.1. Produce only a little amount of ethylene gas and some may not produce it at all

1.1.2. Normally fruits with no starch reserves V

1.2. Climacteric fruits

1.2.1. Produces a lot of ethylene gas and releases the gas to surroundings

1.2.2. Normally fruits with starch reserves

2. HARVEST STAGES

2.1. DEVELOPMENT

2.1.1. Starts with the formation of the edible part

2.1.2. Setting of fruit Swelling of a root, tuber or bulb Elongation of a stalk or petiole

2.1.3. During the development or growth period of fruits there are many chemical and physical changes taking place have bearing on: 1-fruit quality 2-postharvest behaviour

2.2. PRE-MATURATION

2.2.1. Starts with development and lasts until the edible portion reaches a usable, but not particularly desirable condition

2.3. MATURATION

2.3.1. Overlaps pre-maturation and is followed by senescence

2.3.2. It begins before harvest BUT may continue after harvest

2.4. RIPENING

2.4.1. Some fruits will not ripen properly while still attached to the tree

2.4.2. Ripening normally occurs in fruit after growth ceases by using ethylene, ingredient for ripening

2.5. SENESCENCE

2.5.1. At this stage, growth has ceased and the process of aging replace the changes of ripening

2.5.2. May start before or after harvest - believed that respiration climacteric marks the beginning of senescence

2.5.3. Senescence ends when the product is no longer usable as a food for human consumption

3. HARVEST METHODS

3.1. TYPES OF HARVESTING

3.1.1. Manual

3.1.1.1. To gather a commodity/ produce from the field at the proper level of maturity, with a minimum damage and loss, as rapidly as possible and at a minimum cost

3.1.1.2. Some of the tools / equipment used for harvesting includes: *Knife *Pole *Rope *Basket *Ladder *Sickle *Scissor

3.1.2. Mechanical

3.1.2.1. Harvesting machinery or equipment is a mechanical device used for harvesting. There are several types of harvesting machines which are generally classified by crop

3.1.2.2. Reapers are used for cutting cereal grains, threshers for separating the seed from the plant; whereas corn or maize harvesting is performed by employing a specially designed mechanical device ' mechanical corn pickers

4. Respiration

4.1. Thus, reducing the rate of respiration is an important consideration in extending the postharvest life of a fruit or vegetable and optimizing postharvest quality

4.2. Despite having been detached from the plant, fruits and vegetables remain as living organs after harvest.

4.3. Respiration continues, compounds that affect plant flavor, sweetness, weight, turgor (water content), and nutritional value are lost.

5. Ethylene

5.1. Ethylene is a colorless gas that is naturally produced by plants and functions as a plant growth regulator.

5.2. It triggers specific events during a plant’s natural course of growth and development, such as ripening.

6. POST HARVEST INJURIES

6.1. Post-harvest losses are losses occurring in the period between harvesting and consumption

6.2. Direct causes of PH loses

6.2.1. Mechanical Injury

6.2.1.1. Losses caused by mechanical injuries include cuts, bruises, abrasions and punctures and can be categorised into four major types of injuries

6.2.2. Physical & Environment

6.2.2.1. Physical and environmental losses include the various responses of produce to excessive or insufficient heat, cold, gases or humidity

6.2.3. Biological & Physiological

6.2.3.1. Chemical and biochemical losses include undesirable reactions between chemical compounds and contamination with harmful substances such as certain pesticides

6.2.4. Biological & Microbiological

6.2.4.1. Biological and microbiological losses refer to the consumption of or damage to produce by insects, birds, rodents, bacteria, etc

6.2.5. Other Indirect Post Harvest Injuries

6.2.5.1. *Consumers' demand. *Inadequate marketing systems. *Facilities. (Limited storage, cold room, drying and transport) *Policy changes (e.g. agricultural diversification, quality standards, price policy) *Lack of training and awareness among people involved in the marketing system. *Underdeveloped infrastructure (roads, harbour facilities). *Cost of transport. *Unreliable supplies of packaging or high cost of packaging