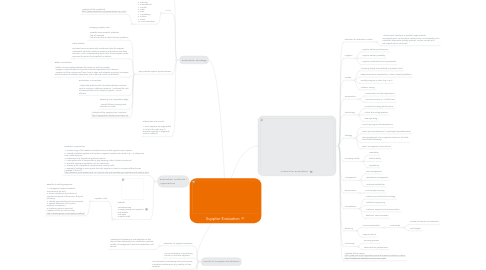

1. Goals of Supplier Evaluation

1.1. Definition for Supplier Evaluation

1.1.1. Assessment of existing or new suppliers on the basis of their delivery, prices, production capacity, quality of management, technical capabilities, and service.

1.2. The concentration of purchasing volume on the best suppliers

1.3. The decrease in purchasing costs and increase in supplier performance (e.g. quality, on time delivery)

1.4. The improvement of co-operation

1.5. The optimization of the entire value chain in collaboration with our suppliers

2. Evaluation Strategy

2.1. Definition for Evaluation Strategy

2.1.1. Strategic learning and evaluation gives a variety of methods and processes to provide time-conserning, credible, and useful information that can be acted upon to increase organizational effectiveness and impact

2.2. 10 C's

2.2.1. 1. Competency. 2. Capacity. 3. Commitment. 4. Control. 5. Cash. 6. Cost. 7. Consistency. 8. Culture. 9. Clean. 10. Communication.

2.2.1.1. (Website of the Mindtools) http://www.mindtools.com/pages/article/10-cs.htm

2.3. Why evaluate supplier performances?

2.3.1. Managing supplier risks - possible environmental problems - lack of materials - lack of cash flow or other financial problems

2.3.2. Fewer defects Increased communication with customers helps the supplier understand, what the customer needs and what does and does not work. When understanding these facts, the processes can be improved to reduce the potential for defects.

2.3.3. Better coordination - better communication between the customer and the supplier - supplier is placed better to meet the business objectives of its customer - supplier and the customer will learn how to align and integrate practices, processes and procedures to enable cooperation and to be even more consolidated

2.3.4. Evaluations As Incentives - helps with problems like: the administration involved, such as invoices or delivery notes etc. It reduces the cost of administration of the supply of goods -->more efficient.

2.3.5. Retaining The Competitive Edge - overall efficiency savings and reduction in costs

2.3.6. (Website of the Supply-Chain-Mechanic) http://supplychain-mechanic.com/?p=128

2.4. Defines two main points: 1. How suppliers are segmented 2. What is the right way to evaluate suppliers in segments (Lecture material)

3. Evaluation Methods / Approaches

3.1. Evaluation Approaches: 1. Provide copy of the reseller's business licence to the supplier upon request. 2. Classify multiple suppliers and vendors. Segment vendors into levels, e.g. 1,2,3 based on how critical they are. 3. Determine how suppliers ship their products. 4. Ask supplier who is responsible to pay shipping costs of orders (incoterms) 5. Evaluate supplier's reputation, ask for references. 6. Prepare a list of questions (questionnaire, survey, audit) 7. Request a catalog or price quote from the supplier in order to compare offered prices (Website of the Inc.) http://www.inc.com/guides/2010/12/7-tips-to-rate-and-evaluate-your-suppliers-and-vendors.html

3.2. Methods: - Questionnaires - Surveys (quality and supplier) - Scorecards - Site visits - Supplier audit

3.2.1. Supplier Audit

3.2.1.1. Benefits of auditing suppliers: 1. Management system standard requirements are met. 2. Gives confidence of products of suppliers and parts of the service they are providing 3. Identify opportunities of improvements 4. Reduce downtime due to poor products of supplier's 5. Customer service improved (Website of the ISO 9001Group) http://iso9001group.com/supplier-auditing/

4. Criteria for Evaluation

4.1. Definition for Evaluation Criteria

4.1.1. A benchmark, standard, or yardstick against which accomplishment, conformance, performance, and suitability of an individual, alternative, activity, product, or plan, as well as of risk-reward ratio is measured.

4.2. Logistics

4.2.1. Supplier delivery performance

4.2.2. Supplier delivery reliability

4.2.3. Supplier meets lead time requirements

4.3. Quality

4.3.1. Incoming quality and reliability in process / field

4.3.2. Responsiveness & cooperation in case of quality problems

4.3.3. Quality program in place (e.g. TQM)

4.3.4. Problem solving

4.4. Cooperation

4.4.1. Cooperation of sales department

4.4.2. Corrective active (CAP) fulfillment

4.5. Technology

4.5.1. Current technology performance

4.5.2. Future tehcnology position

4.5.3. R&D spending

4.6. Strategy

4.6.1. Current pricing & cost transparency

4.6.2. Future price development / roadmaps (competitiveness)

4.6.3. The management of our suppliers, based on the total cost of the relationship

4.6.4. Senior management commitment

4.7. Company profile

4.7.1. Ownership

4.7.2. Global ability

4.7.3. Depedency

4.8. Management

4.8.1. Risk management

4.8.2. Operations management

4.8.3. Customer satisfaction

4.9. Environment

4.9.1. Eco-friendly company

4.10. Competence

4.10.1. Product and industrial technology

4.10.2. Industrial engineering

4.10.3. Customer support and communication

4.10.4. Electronic communication

4.11. Economy

4.11.1. Financial Evaluation

4.11.1.1. Productivity

4.11.1.1.1. Process of internal cost reduction

4.11.1.1.2. Cost targets

4.11.2. Payment terms

4.12. Purchasing

4.12.1. Sourcing process

4.12.2. Subcontractor performance