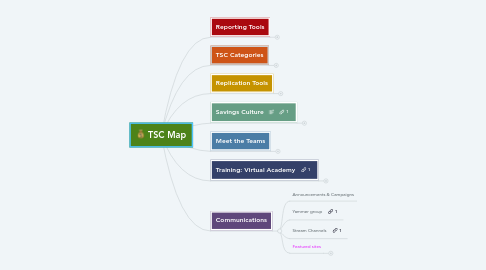

1. Reporting Tools

1.1. Finance Reporting

1.1.1. Training page

1.1.2. IBP Training Hub

1.2. EST

1.2.1. Viewer

1.2.2. Editor

1.2.2.1. Training Page

2. TSC Categories

2.1. Labor

2.1.1. About

2.1.2. Platforms

2.1.2.1. Advance process and equipment control

2.1.2.2. Distribution and shifts structure

2.1.2.3. High cost automation

2.1.2.4. Labor health automation and control

2.1.2.5. Layout optimization

2.1.2.6. Low cost automation

2.1.2.7. Polyvalence

2.1.2.8. Secondary processes optimization

2.1.2.9. Smart outsourcing

2.1.3. Labor Analyzer Solution

2.1.4. Manning

2.1.5. Best Practices

2.1.6. Gallery

2.1.7. Additional Materials

2.1.8. Bank of Success Cases

2.2. Raw Materials

2.2.1. About

2.2.2. Platforms

2.2.2.1. Cullet Consumption optimization

2.2.2.2. Soda Ash Reduction

2.2.2.2.1. One Pager

2.2.2.2.2. Compositions Tool

2.2.2.3. Waste Batch Reduction

2.2.2.3.1. One Pager

2.2.2.3.2. Color Changes

2.2.2.4. Other batch reformulations

2.2.2.4.1. Compositions Tool

2.2.2.5. RM Inventories Optimization

2.2.2.5.1. One Pager

2.2.2.5.2. NFG Inventory

2.2.3. Bank of Success Cases

2.3. Energy

2.3.1. About

2.3.2. Platforms

2.3.2.1. Compressed air and Vacuum

2.3.2.1.1. One Pager

2.3.2.2. Furnace energy

2.3.2.2.1. One Pager

2.3.2.2.2. Stability Curve (Metric)

2.3.2.2.3. Stability Curve (Imperial)

2.3.2.3. Gas systems

2.3.2.3.1. One Pager

2.3.2.4. Lighting

2.3.2.4.1. One Pager

2.3.2.5. VSD, fans and Motors

2.3.2.5.1. One Pager

2.3.2.6. Energy meters and monitoring system

2.3.2.6.1. One Pager

2.3.2.7. Energy efficiency partnership

2.3.2.7.1. One Pager

2.3.2.8. Waste heat recovery

2.3.2.8.1. One Pager

2.3.3. Bank of Success Cases

2.4. M&E

2.4.1. About

2.4.2. Platforms

2.4.2.1. Surface Treatment Consumption

2.4.2.2. IS Machine Lubric. Consumption

2.4.2.3. IS Delivery & Shear Lubric. Consumption

2.4.2.4. Swabbing & Sooting Consumption

2.4.3. Bank of Success Cases

2.5. Other COP

2.5.1. About

2.5.2. Bank of Success Cases

2.6. Molds

2.6.1. About

2.6.2. Bank of Success Cases

2.7. One Way Packaging

2.7.1. About

2.7.2. Bank of Success Cases

2.8. CapEx & M&E901, Project Efficiency, Asset stability

2.8.1. Bank of Success Cases

2.9. Production Volume

2.9.1. Bank of Success Cases

2.10. Quality

2.10.1. Bank of Success Cases

2.11. Logistics

2.11.1. Bank of Success Cases

2.12. Planning

2.12.1. Bank of Success Cases

2.13. Forming

3. Replication Tools

3.1. Platform Projects Viewer

3.2. Bank of Success Cases

3.3. Boosting Replication Initiative

3.3.1. Training Plan

3.3.1.1. Power BI Replication Map

3.3.1.2. Categories & Platforms

3.3.1.3. EST Editor Training

3.3.1.4. Capex Request Criteria

3.3.2. Plant_Indicators

3.3.2.1. Leading

3.3.2.1.1. # actionable project adoptions and executions on selected plants to reduce materialy spend without CapEx

3.3.2.1.2. #actionable project adoptions and executions on selected plants to reduce materialy spend with CapEx

3.3.2.2. Lagging

3.3.2.2.1. $ identified in % of COGS PY

4. Savings Culture

4.1. Smart Spend Culture

4.1.1. 5Yr Cultural Transformation Journey

4.1.2. Smart Spend Program

4.1.2.1. 6-Step Framework

4.1.2.2. 3-Core behaviors

4.1.3. Supporting Network

4.1.3.1. Smart Spend Ambassadors

4.1.3.2. Key Stakeholders

4.1.4. Training (Playbook/BP)

4.1.4.1. Desired Leadership Readiness

4.1.4.1.1. BP Replication

4.1.4.1.2. Lean/Kaizen Philosophy

4.1.4.1.3. Connection with MOE

4.1.4.1.4. Connection with OIS

4.1.4.2. Desired Skills & Behaviors

4.1.4.2.1. Hard Skills

4.1.4.2.2. Soft Skills: Behaviors

4.1.4.3. Desired Recognition System (Guidelines)

4.2. Plant Maturity Assessment (PMA)

4.2.1. Assessment 1 - Plant Ledership Readiness

4.2.2. Assessment 2 - Role-Knowledge

4.2.2.1. Hard Skills

4.2.2.1.1. Lean/Kaizen toolkit

4.2.2.1.2. Replication Map

4.2.2.1.3. Financial acumen

4.2.2.1.4. IBP Cycle

4.2.2.1.5. BPs in Plant Controlling

4.2.2.1.6. TSC Tools for Data Driven analysis

4.2.2.2. Soft Skills: Behaviors

4.2.2.2.1. Model and demand Accountability

4.2.2.2.2. Prioritize and make sound decisions

4.2.2.2.3. Deliver Results

4.2.3. Assessment 3- Plant Recognition

4.3. Plant Maturity Indicators (PMI)

4.3.1. Leading

4.3.1.1. Employee survey on behaviors

4.3.2. Lagging

4.3.2.1. % Improvement of the 3 Assessments

4.3.2.1.1. Score 1 - Plant Leadership Readiness

4.3.2.1.2. Score 2- Role-Knowledge

4.3.2.1.3. Score 3 - Assessment Score Plant Recognition

4.3.2.2. Total Score 3 Assesments

4.4. Plant Maturity Best Practices (MBP)

4.4.1. MBP1 - Building Leadership Readiness

4.4.2. MBP2 - Boosting Knowledge

4.4.2.1. Training Materials: Hard Skills

4.4.2.1.1. Lean/Kaizen toolkit

4.4.2.1.2. Replication Map

4.4.2.1.3. Financial acumen

4.4.2.1.4. IBP Cylce

4.4.2.1.5. BPs in Plant Controlling

4.4.2.1.6. TSC Tools for Data Driven analysis

4.4.2.2. Training Materials: Soft Skills

4.4.2.2.1. Model and demand Accountability

4.4.2.2.2. Prioritize and make sound decisions

4.4.2.2.3. Deliver Results

4.4.3. MBP3 - Recognition Systems

5. Meet the Teams

5.1. TSC CoE

5.2. CG Integrators

5.2.1. Community Wheel

5.3. Plant Management Teams

5.3.1. Network Inactive Users

5.3.2. Plant CI Leaders

5.3.3. Plant Controllers

5.3.4. Plant HR Managers

5.4. Coalition

5.4.1. OIS Team

5.4.2. GMF Team

5.4.3. Org. Charts

6. Training: Virtual Academy

6.1. TSC Onboarding

6.2. Continuous Improvement Toolkit

6.3. IBP Training Hub

7. Communications

7.1. Announcements & Campaigns

7.2. Yammer group

7.3. Stream Channels

7.4. Featured sites

7.4.1. OIS

7.4.2. GMF (Book O-I)

7.4.3. EHS Toolkit (Safety Shares)

7.4.4. Enterprise Monitor

7.4.5. Global Metrics