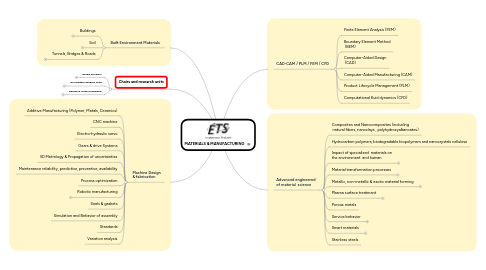

1. Built Environment Materials

1.1. Buildings

1.1.1. Composites

1.1.2. Concrete - masonry

1.1.3. In-service behavior

1.1.3.1. Dynamic

1.1.3.2. Reinforcement

1.1.3.3. Seismic analysis

1.1.3.4. Soil-structure interaction

1.1.3.5. Wear

1.1.4. Lyfecycle

1.1.4.1. Rehabilitation

1.1.4.2. Sustainable Development

1.1.5. Wood

1.2. Soil

1.2.1. Analysis

1.2.2. Behavior

1.2.3. Characterization

1.2.4. Sustainable development

1.3. Tunnels, Bridges & Roads

1.3.1. Asphalt & Recycled

1.3.1.1. Composition & Composites

1.3.1.2. In-service behavior

1.3.1.2.1. Acoustical

1.3.1.2.2. Rheological

1.3.1.2.3. Seismic analysis

1.3.1.2.4. Thermal

1.3.1.3. Lifecycle

1.3.1.3.1. Maintenance

1.3.1.3.2. Sustainable development

1.3.2. Concrete

1.3.2.1. Composites - reinforced

1.3.2.2. In-service behavior

1.3.2.2.1. Acoustical

1.3.2.2.2. Rheological

1.3.2.2.3. Seismic analysis

1.3.2.2.4. Thermal

1.3.2.3. Lifecycle

1.3.2.3.1. Maintenance

1.3.2.3.2. Réhabilitation

1.3.2.3.3. Sustainable development

2. Chairs and research units

2.1. Research chairs

2.1.1. Canada Research Chair in Biomaterial and Endovascular Implants

2.1.2. Industrial Research Chair in Forming Technologies of High-Strength Alloys

2.2. Accredited research units

2.2.1. DYNAMO – Research Laboratory in Machine, Process and Structural Dynamics

2.2.2. LIPPS – Products, Processes and Systems Engineering Laboratory

2.3. Research units recognized

2.3.1. ACEFE – Stress Analysis by Finite Element and Testing Laboratory

2.3.2. LAMSI – Shape Memory Alloys and Intelligent Systems Laboratory

2.3.3. LFCMC – Composite Materials Manufacturing and Characterization Laboratory

2.3.4. LOPFA – Optimization of Aerospace Manufacturing Processes Laboratory

3. Machine Design & fabrication

3.1. Additive Manufacturing (Polymer, Metals, Ceramics)

3.2. CNC machine

3.3. Electro-hydraulic servo

3.4. Gears & drive Systems

3.5. 3D Metrology & Propagation of uncertainties

3.6. Maintenance reliability, predictive, preventive, availability

3.7. Process optimization

3.8. Robotic manufacturing

3.8.1. Artificial Intelligence

3.8.2. Design, modelization, simulation & analysis of pneumatic and hydraulic systems

3.8.3. Image processing / pattern recognition / artificial vision

3.8.4. Intelligent control of electrical drives and robots precision

3.9. Seals & gaskets

3.10. Simulation and Behavior of assembly

3.11. Standards

3.12. Variation analysis

4. CAD-CAM / PLM / FEM / CFD

4.1. Finite Element Analysis (FEM)

4.2. Boundary Element Method (BEM)

4.3. Computer-Aided Design (CAD)

4.4. Computer-Aided Manufacturing (CAM)

4.5. Product Lifecycle Management (PLM)

4.6. Computational fluid dynamics (CFD)

5. Advanced engineered of material science

5.1. Composites and Nanocomposites (including natural fibers, nanoclays , polyhydroxyalkanoates)

5.2. Hydrocarbon polymers, biodegradable biopolymers and nanocrystals cellulose

5.3. Impact of specialized materials on the environment and human

5.3.1. Analysis of the sources of air pollution for workers

5.3.2. Clean machining

5.3.3. Industrial waste management

5.3.4. Nanotoxicology

5.3.5. Treatment of industrial effluents

5.4. Material transformation processes

5.4.1. Additive Manufacturing

5.4.2. Brazing

5.4.3. Contour hardening

5.4.4. Generation of machining lines / manufacturing

5.4.5. High-performance removal of materials

5.4.6. Surface treatment

5.4.7. Welding

5.5. Metallic, non-metallic & exotic material forming

5.5.1. Hot spinning

5.5.2. Hydroforming

5.5.3. Process simulation (FEM, cellular automata, self-consistent models)

5.6. Plasma surface treatment

5.6.1. Biomechanical applications

5.6.2. Hydrophobization cellulosic surfaces (inert and organic materials)

5.6.3. Hydrophobization of surfaces

5.7. Porous metals

5.8. Service behavior

5.8.1. Fatigue Analysis

5.8.2. Corrosion

5.8.3. Creep

5.8.4. Residual stresses

5.8.5. Seams and joints

5.8.6. Tribology / Rheology

5.8.7. Wave propagation

5.9. Smart materials

5.9.1. Hydro rheological fluid

5.9.2. Magnetorheological fluids

5.9.3. Nanomaterials

5.9.4. Shape memory alloys