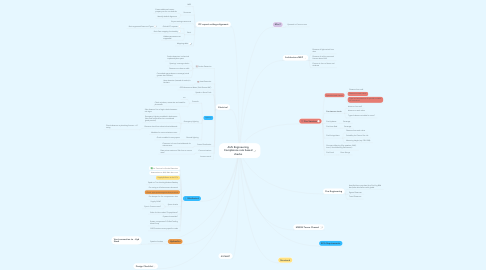

1. Vent connection to - Hyd Stack

2. Electrical

2.1. Smoke Detection

2.1.1. Smoke detection in electrical cupboard/plant space

2.1.2. Spacing/ coverage checks

2.1.3. Detectors to close to walls

2.1.4. Concealed space detector coverage (voids greater than 800mm)

2.2. Heat Detection

2.2.1. Heat detection (instead of smoke) in kitchens

2.3. GPO distance to Water (Sink/Shower/WC)

2.4. Speak to Steve Cook

2.5. Lighting

2.5.1. Controls

2.5.1.1. cvc

2.5.1.2. Check windows, rooms size and need for photocells

2.5.2. Emergency lighting

2.5.2.1. 24m distance/ line of sight checks between exit signs

2.5.2.2. Emergency lighting modeled in bathrooms (Not code requirement but considered good practice)

2.5.2.3. Distance check from electrical switchboards

2.5.2.3.1. Check distances to plumbing fixtures -> IP rating

2.5.2.4. Modeled in communications room

2.5.3. General lighting

2.5.3.1. Check modeled in every space

2.6. Power Distribution

2.6.1. Clearance in front of switchboards for maintenance

2.7. Communications

2.7.1. Data points maximum 90m from a comms room

2.8. Access control

3. Fire Services

3.1. Sprinkler head checks

3.1.1. Distance from wall

3.1.2. Distance to each other

3.1.3. Type and temperature of sprinkler suitable for room/area

3.2. Fire detector checks

3.2.1. distance from wall

3.2.2. distance to each other

3.2.3. Type of detector suitable for room?

3.3. Fire Hydrants

3.3.1. Coverage

3.4. Fire Hose Reel

3.4.1. Coverage

3.5. Fire Extinguishers

3.5.1. Distance from each other

3.5.2. Suitability for Class of fire risk

3.5.3. Mounting height (top 750-1200)

3.6. Occupant Warning (Fire speakers, EWS, horns, Visual Warning Devices etc)

3.7. Fire Panel

3.7.1. Door Swings

4. Mechanical

4.1. Air Terminal vs Smoke Detection

4.2. Attenuation on AHU Main duct runs

4.3. Supply & Retun air for FCU

4.4. Speak to Tom Hocking/Andrew Beazley

4.5. Fire rating on Kitchen extract ductwork

4.6. Check pipe systems against best practice

4.7. Fire damper for fire compartment rules

4.8. Space checks

4.8.1. Supply Grille?

4.8.2. Pipe in Comms room?

4.9. Rules for Vent codes? Copmpliance?

4.10. Pipework materials?

4.11. System components? Chiller/Cooling tower/Pump

4.12. GRS Contains country specific codes

5. Hydraulics

5.1. Speak to Andrea

6. Misc?

6.1. Pipework in Comms room

7. Structural

8. Design Checklist

9. MSSSN Teams Channel

10. Fire Engineering

10.1. Kate Buckle to populate (Aus Fire Eng BIM lead) after discussions with global

10.2. Egress Distances

10.3. Travel Distances

11. AS1668?

12. Architecture MEP

12.1. Distance of light switch from door

12.2. Distance of ceiling mounted fixtures above floor

12.3. FIxtures in front of doors and windows

13. IFC export settings alignment

13.1. MEP

13.2. Structures

13.2.1. Create additional custom property set for non defaults

13.2.2. Identify default alignment

13.3. Export settings rescources

13.4. Revit

13.4.1. Github IFC exporter

13.4.1.1. Revit supported Psets and Types

13.4.2. Revit Pset mapping functionality

13.4.3. Hidden parmaaters not supported!