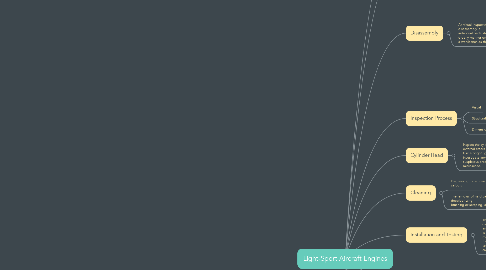

1. General Overhaul Procedures

1.1. Any engine to be overhauled completely should receive a runout check of its crankshaft or propeller shaft as a first step.

2. Receiving Inspection

2.1. The receiving inspection consists of determining the general condition of the total engine as received, along with an inventory of the engine’s components.

3. Disassembly

3.1. As visual inspection immediately follows disassembly, all individual parts should be laid out in an orderly manner on a workbench as they are removed

3.1.1. Drain the engine oil sumps and remove the oil filter. Drain the oil into a suitable container; strain it through a clean cloth. Check the oil and the cloth for metal particles.

3.1.2. Dispose of all safety devices (safety wire, cotter pins, etc.) as they are removed. Never use them a second time. Always replace with new safety devices.

3.1.3. All loose studs, and loose or damaged fittings, should be carefully tagged to prevent being overlooked during inspection

3.1.4. Always use the proper tool for the job. Use sockets and box end wrenches wherever possible. If special tools are required, use them rather than improvising.

4. Inspection Process

4.1. Visual

4.2. Structural NDT

4.3. Dimensional

5. Cylinder Head

5.1. Inspect the cylinder head for internal and external cracks. Use a bright light to inspect for cracks, and investigate any suspicious areas with a magnifying glass or microscope.

6. Cleaning

6.1. Degreasing to remove dirt and sludge (soft carbon)

6.2. The removal of hard carbon deposits by decarbonizing, brushing or scraping, and grit-blasting.

7. Installation and Testing

7.1. The procedures and equipment used in determining that an engine is ready for airworthy service and is in excellent mechanical condition, normally requires the use of a test stand, or test cell, although the aircraft can be used.

8. Reciprocating Engine Operation

8.1. The operation of the powerplant is controlled from the cockpit or flight deck. Some installations have numerous control handles and levers connected to the engine by rods, cables, bellcranks, pulleys, etc

9. Engine Instruments

9.1. 1. Crankshaft speed (rpm) 2. Manifold pressure 3. Cylinder head temperature 4. CAT 5. Oil temperature 6. Oil pressure 7. Fuel pressure 8. Fuel flow meter 9. Fuel/air mixture setting

10. Ground Check

10.1. The ground check is performed to evaluate the functioning of the engine by comparing power input, as measured by manifold pressure, with power output, as measured by rpm or torque.

10.1.1. 1. Control position check 2. Cowl flaps (if equipped)—open 3. Mixture—rich 4. Propeller—high rpm 5. Carburetor heat—cold 6. Check propeller according to propeller manufacturer’s instruction. 7. Open throttle to the run-up rpm setting as per manufacturer’s instructions (specified RPM and manifold pressure). 8. Ignition system operational check