1. Responsibility's

1.1. Worker

1.1.1. 1. Understand and follow the safety program and jobsite work procedures.

1.1.1.1. 2. Wear appropriate clothing & required PPE.

1.1.1.1.1. 3. Do not take unnecessary risks or endanger other workers with horseplay.

1.2. Supervisor

1.2.1. 1. All workers are familiar with and follow the company Safety program.

1.2.1.1. 2. Workers are properly trained & follow the (WHMIS) program, safe procedures, & the Occupational Health and Safety Regulation.

1.2.1.1.1. 3. The jobsite is evaluated & Hazards are eliminated or minimized. If they cant be controlled, special work procedures must be developed to prevent the risk of any incidents.

1.3. Employer

1.3.1. 1. Develop, implement & maintain a Safety program designed to prevent injuries and disease in the workplace.

1.3.1.1. 2. Evaluate worksite hazards & taking necessary steps to protect workers.

1.3.1.1.1. 3. Ensure Proper (WHMIS) program is in place, including worker education & training.

1.4. Prime Contractor

1.4.1. 1. A construction site safety program is developed and followed.

1.4.1.1. 2. The occupational health and safety activities of all subcontractors are coordinated.

1.4.1.1.1. 3. The Occupational Health and Safety Regulation is complied with by all worksite contractors and subcontractors.

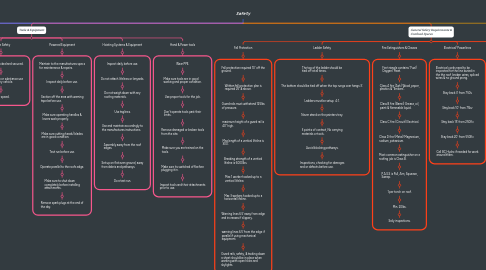

2. PPE

2.1. Personal protective equipment and clothing

2.1.1. Hard Hats

2.1.1.1. Hearing Protection

2.1.1.1.1. Eye & Face Protection

3. Tools & Equipment

3.1. kettles & Tankers

3.1.1. 5 cylinders of 1100lbs can be transported without TDG training.

3.1.1.1. They must be transported in an open vehichle, labels out, & strapped upright.

3.1.1.1.1. Barricades should be 20' away from kettles.

3.2. Propane

3.2.1. Wear gloves, safety glasses, & long sleeves when connecting/ disconnecting.

3.2.1.1. Always use a regulator.

3.2.1.1.1. Always operate with the cylinder valve fully open.

3.3. Vehicle Safety

3.3.1. Keep the truck locked and secured.

3.3.1.1. Do not horseplay or substance use around a company vehicle.

3.3.1.1.1. Never speed.

3.4. Powered Equipment

3.4.1. Maintain to the manufactures specs for maintenance & repairs.

3.4.1.1. Inspect daily before use.

3.4.1.1.1. Section off the area with warning tape before use.

3.5. Hoisting Systems & Equipment

3.5.1. Inspect daily before use.

3.5.1.1. Do not attach lifelines or lanyards.

3.5.1.1.1. Do not weigh down with any roofing materials.

3.6. Hand & Power tools

3.6.1. Wear PPE.

3.6.1.1. Make sure tools are in good working and proper condition.

3.6.1.1.1. Use proper tools for the job.

4. General Safety Requirements & Confined Spaces

4.1. Fall Protection

4.1.1. Fall protection required 10' off the ground.

4.1.1.1. Written fall protection plan is required 25' & above.

4.1.1.1.1. Guard rails must withstand 125lbs of pressure.

4.2. Ladder Safety

4.2.1. The top of the ladder should be tied off at all times.

4.2.1.1. The bottom should be tied off when the top rungs over hangs 3'.

4.2.1.1.1. Ladders must be setup 4:1.

4.3. Fire Extinguishers & Classes

4.3.1. Fire triangle contains "Fuel/ Oxygen/ Heat.

4.3.1.1. Class A fire (Ash) Wood, paper, plastics & "Embers".

4.3.1.1.1. Class B fire (Barrel) Grease, oil, paint & flammable liquid.

4.4. Electrical/ Powerlines

4.4.1. Electrical cords need to be inspected for the line buried in the the roof, broken wires, spliced wires & no ground prong.

4.4.1.1. Stay back 3' from 750v

4.4.1.1.1. Stay back 10' from 75kv

4.5. Job-setup

4.5.1. 1. Job location.

4.5.1.1. 2. Proper PPE.

4.5.1.1.1. 3. Proper tools in good working condition.

4.6. Job-Planning

4.6.1. Site safety plans.

4.6.1.1. Fall protection.

4.6.1.1.1. Material handling.

4.6.2. Risk & Hazards assessment.

4.6.2.1. Powerline assessment.

4.6.2.1.1. Site inspections.

5. Material Handling

5.1. WHMIS

5.1.1. Workplace Hazardous Material Information System.

5.1.1.1. Worker Education

5.1.1.1.1. Most SDS "Safety Data Sheet" will be on the wall.

5.2. Harmful Substances

5.2.1. Chemicals can enter the bloodstream through lungs, skin & eyes.

5.2.1.1. Do not smoke within 50' of organic solvents.

5.2.1.1.1. When using hazardous products, fire extinguishers, eye wash stations should be readily available.

5.3. Proper lifting/ Handling

5.3.1. 1. Plan your task.

5.3.1.1. 2. Plant your feet.

5.3.1.1.1. 3. Get a good grip.

5.4. Torch on roofs & Propane torches

5.4.1. Stay back 3' from someone using a torch.

5.4.1.1. Use soapy water to check for leaks, if a leak occurs STOP, & fix before you continue.

5.4.1.1.1. 1 20lbs extinguisher per torch.