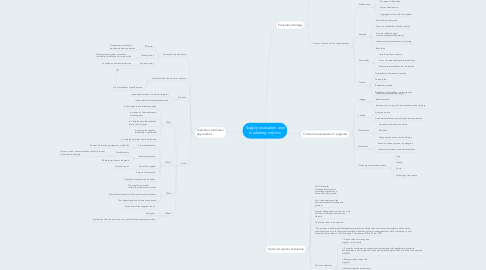

1. Evaluation methods / approaches

1.1. Surveys and questionnaire

1.1.1. RFI survey

1.1.1.1. Prospective, possibility of performnce metrics question

1.1.2. Quality survey

1.1.2.1. Quality plannin system, processes, third-party, certification, corrective action

1.1.3. Supplier survey

1.1.3.1. Localisation, humans ressources

1.2. Scorecards (the most common method)

1.2.1. A lot of elements of performance

1.3. Site visits

1.3.1. review specific issues or problems supplier

1.3.2. review specific buisness process areas

1.4. Audit

1.4.1. Why ?

1.4.1.1. to find capable and reliable suppliers

1.4.1.2. to make a of the performance of the supplier

1.4.1.3. to clarify the possible problems and to find solutions

1.4.1.4. to develop the supplier relationship / partnership

1.4.1.5. to verify the promises and commitments

1.4.2. What ?

1.4.2.1. A pre-questionnaire

1.4.2.1.1. General information, equipement, solvability

1.4.2.2. Audit questionnaire

1.4.2.2.1. Possible topics

1.4.2.2.2. All the topics have to be grade

1.4.2.3. Visit of the supplier

1.4.2.3.1. Notation topics

1.4.2.4. Proposal of correction

1.4.2.5. Checking of correction be well done

1.4.3. Who ?

1.4.3.1. The suppliers for critical materials, products and services

1.4.3.2. Manufacturer products with buyer’s own specifications

1.4.3.3. The biggest suppliers (volume or expenses)

1.4.4. When ?

1.4.4.1. At the time of the supplier's choice

1.4.4.2. Every year

1.4.4.3. Another one after the anual one to control that the corrections are done

2. Criteria for evalutation of suppliers

2.1. Lagging

2.1.1. SCM metrics, operational results

2.1.2. Reactive metrics

2.1.3. Inventory turns, scrap, calls per costumer service employe

2.2. Leading

2.2.1. Proactive metrics

2.2.2. Costumer satisfaction, supplier performance problems

2.3. Quantitative

2.3.1. Empirical performance indicators

2.3.2. Real data

2.3.3. Transportation costs, on-time delivery

2.4. Qualitative

2.4.1. Based on human opignon or perception

2.4.2. customer complaints, customer satisfaction

2.5. Others typical evaluation criteria

2.5.1. Time

2.5.2. Quality

2.5.3. Costs

2.5.4. Technology / Innovation

3. Evaluation strategy

3.1. Segmentation

3.1.1. Kraljic's

3.1.1.1. Strategic suppliers : providing industry expertice, exceeding contractual expectations and proactively managing costs for their customers

3.1.1.2. Leverage suppliers : financial impact, total cost of ownership, good profit margins

3.1.1.3. Bottleneck supplier: create problems due to potential risk of interruption of supply

3.1.1.4. Noncritical suppliers posses lowest level risks and require the least attention.

3.2. Actions in fonction of the segmenetation

3.2.1. Collaborative

3.2.1.1. Lower TCO, promote cost reduction

3.2.1.2. Ecourage collaboration

3.2.1.3. Value added-service

3.2.1.4. Aggregate volume with few supplier

3.2.2. Strategic

3.2.2.1. Patrnership with supplier

3.2.2.2. Focus on availlability, reliability, quality

3.2.2.3. Promote infosharing and costumer/supplier collaboration

3.2.2.4. Implement improvement and cost saving

3.2.2.5. Best value

3.2.3. Commodity

3.2.3.1. Lowest priority to measure

3.2.3.2. Focus on operational performance basics

3.2.3.3. Measure internal stakeholder satisfaction

3.2.4. Custom

3.2.4.1. Operational performance measures

3.2.4.2. Service levels

3.2.4.3. Relationship quality

3.2.4.4. Reliability / predictability - avoid surprises

4. Goals of supplier evaluation

4.1. Goal of supplier management process is to manage suppliers and the services they provide

4.2. Aim : raise awerness of the business context of working with partners

4.3. Supplier management process has to be involved in all stages pf the service lifecycle

4.4. Define the use of value networks

4.5. "The purpose of the Supplier Management process is to obtain value for money from suppliers and to ensure that suppliers perform to the targets contained within their contracts and agreements, while conforming to all of the terms and conditions", Service design, The stationery Office,30 mai 2007

4.6. The main objectives

4.6.1. 1. Obtain value for money from supplier and contracts

4.6.2. 2. Ensure that underpinning contracts and agreements with suppliers are aligned to business needs, and support and align with agreed targets in SLRs and SLAs, in conjunction with SLM

4.6.3. 3. Manage relationships with suppliers

4.6.4. 4. Manage supplier performance

4.6.5. 5. Negotiate and agree contracts with suppliers and manage them through their lifecycle

4.6.6. 6. Maintain a supplier policy and a supporting Supplier and Contract Database (SCD).