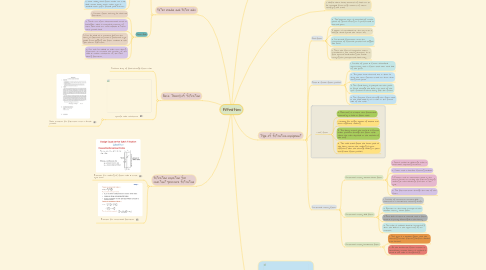

1. Filter media and Filter aids

1.1. Filter media

1.1.1. 1. The filter media must fulfill a number of requirement.

1.1.2. 2. First, must remove the solids to be filtered from the slurry & give a clear filtrate.

1.1.3. 3. Pores should not become plugged so that the rate of filtration become too slow.

1.1.4. 4. The filter medium must allow filter cake to be removed easily & cleanly

1.1.5. 5. Some widely used filter media are twill duck weave heavy cloth, other type is wooded cloth, paper, felted pads and etc.

1.2. Filter Aids

1.2.1. 1. Certain filter aid may be used aid filtration.

1.2.2. 2. These are often diatomaceous earth or kieselguhr which is composed primarily of silica. Also used are wood cellulose & other inert porous solid.

1.2.3. 3. Can be used as a precoart before the slurry is filltered to prevent gelatinous-type solids from plugging the filter medium & also give clearer filtration.

1.2.4. 4. Can also be added to take care during filtration to increase the porosity of the cake & reduce resistance of the cake during filtration.

2. Basic Theory of filtration

2.1. Pressure drop of fluid through filter cake

2.2. Specific cake resistance

2.2.1. Basic equation for filtration rate in batch process

3. Filtration equation for constant-pressure filtration

3.1. Equation for washing of filter cake & total cycle time

3.2. Equation for continuous filtration

4. 1. Useful where samll amounts of solid are to be removed from large amount of water clarifying the liquid.

5. Introduction

6. Type of filtration equipment

6.1. Bed filter

6.1.1. 2. The bottom layer is composed of coarse pieces of grand resting on a perforated or slotted plate.

6.1.2. 3. Water is introduced at the top onto a baffle which spread the water out.

6.1.3. 4. Continuous filteration until the precipitate of filtered particle has clogged the sand.

6.1.4. 5. Then, the flow is stopped & water introduced in the riverse direction, so it flow upward, backwashing the bud & carrying the precipitated solid away.

6.2. Plate & frame filter presses

6.2.1. 1. Consist of plate & frame assembled alternately with a filter cloth over each side of the plate.

6.2.2. 2. The plate have channels out in them so that the clear filtrate liquid can drain down along each plate

6.2.3. 3. The feed slurry is pumped into the press & flows through the debt into each of the open frames so that slurry fills the frame.

6.2.4. 4. The filtrate flows through the filter cloth & the solid build up as a cake on the frame side of the cloth.

6.3. Leaf filter

6.3.1. 2. Each leaf is a hollow wire framework covered by a sack or filter cloth

6.3.2. 1. Develop for larger volume of volume and more efficient washing

6.3.3. 3. The slurry enters the tank & is forced under pressure through the filter cloth where the cake depositd on the outside of the leaf

6.3.4. 4. The wash liquid follow the same path as the slurry. Hence, the washing is more efficient than the through wishing in plate and frame filter presses.

6.4. Continuous rotary filter

6.4.1. Continuous rotary vacuum drum filter

6.4.1.1. 1. Filters washes & discharge take in continuous repeating sequence.

6.4.1.2. 2. Cover with a suitable filtering medium

6.4.1.3. 3. Rotate and an automatic valve in the centre serves to active the filtering, drying, washing & cake discharge function in the cycle.

6.4.1.4. 4. The filtrate leave through the axle of the filter.

6.4.2. Continuous rotary disk filter

6.4.2.1. 1. Consist of concentric vertical disk mounted on a horizontal rotating shaft.

6.4.2.2. 2. Operate on the same principle as the vacuum rotary- drum filter

6.4.2.3. 3. Each disk is hollow & covered with a filter cloth & is partly submerged in the slurry.

6.4.2.4. 4. The cake is washed, dried & scraped off when the disk is in the upper half of its rotation.

6.4.3. Continuous rotary horizontal filter

6.4.3.1. 1. This type is a vacuum filter with the rotating annular filtering surface divided into sectors.

6.4.3.2. 2. As the horizontal filter rotate, it successively receive slurry, is washed, is dried & the cake is scraped off.