Operations Monitoring

da Mahesh Kumar T

1. Manpower

1.1. Non-availability

1.1.1. Shortage of Manpower

1.1.2. Absence of Manpower

1.1.2.1. Planned Absence viz., informed leaves

1.1.2.2. Unplanned Absence viz., health, uninformed

1.2. Availability

1.2.1. Character

1.2.2. Capability

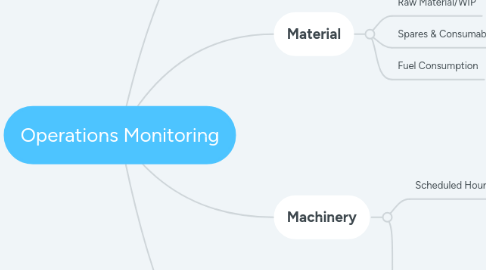

2. Material

2.1. Raw Material/WIP

2.2. Spares & Consumables

2.3. Fuel Consumption

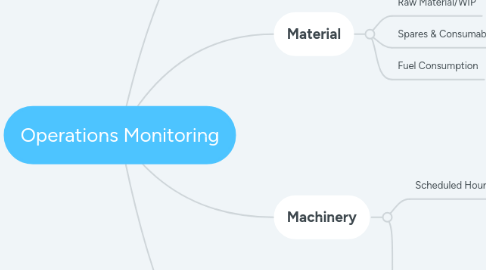

3. Machinery

3.1. Scheduled Hours

3.1.1. Utilized Hours

3.1.1.1. Productive Hours

3.1.1.2. Unproductive Hours

3.1.1.2.1. Resource Waiting/Scheduling

3.1.1.2.2. Non-value adding viz., Inspection, Fuelling etc.

3.1.2. Unutilized Hours

3.1.2.1. Minor Breakdowns

3.1.2.2. Breaks viz., Lunch/Tea, Shift Changes

3.2. Unscheduled Hours

3.2.1. Planned Maintenance

3.2.2. Major Breakdowns