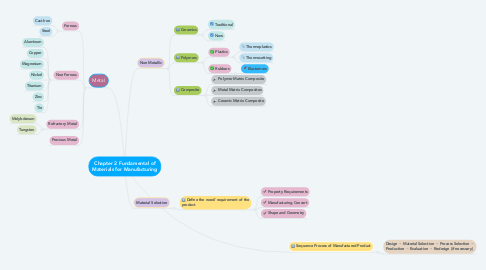

Chapter 2 Fundamental of Materials for Manufacturing

Door wen ong

1. Sequence Process of Manufactured Product

1.1. Design → Material Selection → Process Selection → Production → Evaluation → Redesign (if necessary)

2. Non Metallic

2.1. Ceramics

2.1.1. Traditional

2.1.2. New

2.2. Polymers

2.2.1. Plastics

2.2.1.1. Thermoplastics

2.2.1.2. Thermosetting

2.2.2. Rubbers

2.2.2.1. Elastomers

2.3. Composite

2.3.1. Polymer Matrix Composite

2.3.2. Metal Matrix Composites

2.3.3. Ceramic Matrix Composite

3. Material Selection

3.1. Define the need/ requirement of the product

3.1.1. Property Requirements

3.1.2. Manufacturing Concert

3.1.3. Shape and Geometry

4. Metal

4.1. Ferrous

4.1.1. Cast Iron

4.1.2. Steel

4.2. Non Ferrous

4.2.1. Aluminum

4.2.2. Copper

4.2.3. Magnesium

4.2.4. Nickel

4.2.5. Titanium

4.2.6. Zinc

4.2.7. Tin

4.3. Refractory Metal

4.3.1. Molybdenum

4.3.2. Tungsten