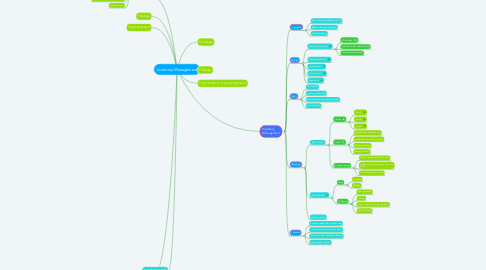

1. Techniques

1.1. Good personnel

1.2. Pilferage

1.3. Tight control of incoming shipments

1.4. Effective control

2. Good personnel

3. Pilferage

4. Effective control

5. Inventory records

6. Shrinkage

7. Pilferage

8. Tight control of incoming shipments

9. Inventory Management

9.1. Importance

9.1.1. One of the most expensive assets

9.1.2. Balance inventory investment

9.1.3. Customer Service

9.2. Models

9.2.1. Independent demand

9.2.1.1. (EOQ) model

9.2.1.2. Production order quantity model

9.2.1.3. Quantity discount model

9.2.2. Dependent demand

9.2.3. Holding costs

9.2.4. Ordering costs

9.2.5. Setup costs

9.3. Types

9.3.1. Raw material

9.3.2. Work-in-process (WIP)

9.3.3. Maintenance/repair/operating (MRO)

9.3.4. Finished goods

9.4. Managing

9.4.1. ( ABC ) Analysis

9.4.1.1. Classes

9.4.1.1.1. Class A

9.4.1.1.2. Class B

9.4.1.1.3. Class C

9.4.1.2. Criteria

9.4.1.2.1. High shortage or holding cost

9.4.1.2.2. Anticipated engineering changes

9.4.1.2.3. Delivery problems

9.4.1.2.4. Quality problems

9.4.1.3. Policies employed

9.4.1.3.1. Supplier development for A items

9.4.1.3.2. Tighter physical inventory control for A items

9.4.1.3.3. Care in forecasting A items

9.4.2. Control Service

9.4.2.1. Loses

9.4.2.1.1. Shrinkage

9.4.2.1.2. Pilferage

9.4.2.2. Techniques

9.4.2.2.1. Good personnel

9.4.2.2.2. Pilferage

9.4.2.2.3. Tight control of incoming shipments

9.4.2.2.4. Effective control

9.4.3. Inventory records

9.5. Functions

9.5.1. Anticipate demand & its fluctuations

9.5.2. Control a part of production process

9.5.3. Take advantage of quantity discounts

9.5.4. Hedge against inflation