1. FIELD NOTE

1.1. 85 years ago three hundred shoe factories have sales offices located within a few blocks of each other in Boston

1.2. today, the production and marketing of Nike shoes and apparel involves an elaborate global network of international manufacturing and sales

1.3. the contemporary geography of industry and services is a product of shifting forces

2. WHERE DID THE INDUSTRIAL REVOLUTION BEGIN, AND HOW DID IT DIFFUSE?

2.1. the manufacturing of goods began long before the Industrial Revolution

2.2. Families and communities produced goods in workshops, and merchants traded manufactured products throughout the world

2.2.1. for example, in the towns and villages of India, workshops produced goods made of iron, gold, silver, and brass

2.2.2. India's carpenters were artists as well as artisans, and their work was in demand wherever it could be bought

2.2.3. India's textiles, made on individual spinning wheels and hand looms, were considered the best in the world

2.2.4. within individual homes in rural villages of Great Britain, rural residents spun thread or wove fabric into textiles during the winter months

2.3. with the eventual development of technologies that allowed for mass production, the British were able to bury local industries in Asia and Africa by flooding the market with inexpensive products and forcing their colonies to purchase imported goods

2.4. The Industrial Revolution

2.4.1. during the eighteenth century, markets for European goods were growing, especially in the colonies

2.4.2. the use of molds allowed more consistency in iron parts and increased production of iron components

2.4.3. the steam engine was used to pump water out of coal mines and to power spinning wheels that spun 100 plus spools of threat at a time and to power dozens of looms in a factory all at once, and to create a new mode of transportation: the railroad

2.4.4. railroad and steam ship, Great Britain enjoyed even greater advantages over the rest of the world than it did at the beginning of the Industrial Revolution

2.4.5. the origins of the Industrial Revolution

2.4.5.1. the areas of Great Britian that industrialized earliest were those closest to the resources needed for industrialization

2.5. Diffusion to Mainland Europe

2.5.1. west to east

2.5.2. in the early 1800s, as the innovations of Britain's Industrial Revolution diffused into mainland Europe, the same set of locational criteria for industrial zones applied: proximity to coal fields and connection via water to a port remind crucial to industrial development

2.5.3. a belt of major coal fields extends from west to east through mainland Europe, roughly along the southern margins of the North Europe Lowland-across northern France and southern Belgium, the Netherlands, the German Ruhr, western Bohemia in the Czech Republic, and Silesia in Poland. Colonial empires gave France, Britain, Belgium, the Netherlands, and later, Germany, access to the capital necessary to fuel industrialization and in some cases the raw materials necessary for production

2.5.4. over the last 200 years, the Dutch have radically altered the port of Rotterdam to facilitate transportation and make it the most important port in Europe and a hub of global commerce

2.5.5. London was a particularly attractive site for industry because of its port location on the Thames River and because of its major role in the flow of regional and global capital

2.5.6. London and Paris became, and remain, important industrial complexes because of their commercial and political connectivity to the rest of the world

2.5.7. Germany still ranks among the world's leading producers of both coal and steel and remains Europe's leading industrial power

2.6. Diffusion beyond Europe

2.6.1. the primary industrial regions that stand out on the world map of industrial centers by the 1950s were western Europe, eastern North America, western Russia and Ukraine, and East Asia

2.6.2. North America

2.6.2.1. industries developed along the Great Lakes where canal, river, and lakes connected with railroads on land to move resources and goods in and out of industrial centers

2.6.2.2. coal was the chief fuel for industries at the time

2.6.3. Russia and Ukraine

2.6.3.1. the St. Petersburg region is one of Russia's oldest manufacturing centers

2.6.3.2. after World War I, the newly formed Soviet Union annexed Ukraine and used the rich resources and industrial potential of Ukraine

2.6.3.3. the Soviet Union (and Russia today) was resource rich

2.6.4. East Asia

2.6.4.1. Japan became one of the world's leading industrial countries

2.6.4.2. with limited natural resources, manufacturing in Japan depended upon raw materials imported from other parts of the world

2.6.4.3. in the late 1800s and early 1900s, Japan colonized Korea, Taiwan, and portions of mainland China

2.6.4.4. Japan's dominant region of industrialization and urbanization is the Kanto Plain, it includes the Tokyo-Yokohama-Kawasaki metropolitan area

2.6.4.5. Japan's second largest industrial complex extends from the eastern end of the Seto Inland Sea to the Nagoya area and includes the Kobe-Kyoto-Osaka triangle

3. HOW HAVE THE CHARACTER AND GEOGRAPHY OF INDUSTRIAL PRODUCTION CHANGE?

3.1. globalization is a set of processes that are increasing interactions, deepening relationships, and heightening interdependence without regard to country borders

3.2. improvements in transportation and communication technologies are at the root of globalization

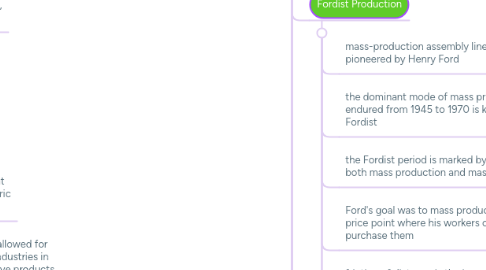

3.3. Fordist Production

3.3.1. mass-production assembly line pioneered by Henry Ford

3.3.2. the dominant mode of mass production that endured from 1945 to 1970 is known as Fordist

3.3.3. the Fordist period is marked by a surge in both mass production and mass consumption

3.3.4. Ford's goal was to mass produce goods at a price point where his workers could afford to purchase them

3.3.5. friction of distance is the increase in time and cost that usually comes with increased distance over which commodities must travel

3.3.6. Agglomeration

3.3.6.1. Alfred Marshal argued that a particular industry, whether automobile manufacturing or furniture production, clusters in an area

3.3.6.2. this process is localization

3.3.6.3. localized industries would attract workers with industry-specific skills, share information, and attract industry-specific support services

3.3.6.4. Alfred Weber developed a basic model explaining where industries would cluster

3.3.6.5. least cost theory focused on a factory owner's desire to minimize three categories of costs

3.3.6.5.1. the first and most important of these categories was transportation

3.3.6.5.2. then labor

3.3.6.5.3. similar to localization; agglomeration

3.4. Flexible Production and Product Life Style

3.4.1. post-Fordist model refers to a set of production processes in which the components of goods are made in different places around the globe and then brought together as needed to meet customer demand

3.4.2. flexible production systems is used to describe this state of affairs because firms can pick and choose among a multitude of suppliers and production strategies in distant places, and then quickly shift their choices in response to adjustments in production costs or consumer demand

3.4.3. these systems are thus designed to respond to consumers who want the newest/best/greatest offering or a custom offering that helps distinguish them for other consumers

3.4.4. changes in the production of a good over time take place as part of a product life cycle

3.4.5. the television production industry has three key elements:

3.4.5.1. research and design

3.4.5.2. manufacture of components

3.4.5.3. assembly

3.5. The Global Division of Labor

3.5.1. global division labor

3.5.1.1. phenomenon whereby corporations and others can draw from labor markets around the world, made possible by the compression of time and space through innovation in communication and transportation systems

3.5.1.2. labor is concentrated in the global economic periphery and semi-periphery to take advantage of lower labor costs

3.5.2. major industrial belt in the United States was in the northeast both because of readily available coal and other raw materials and because of major concentration of the North American population was there

3.5.3. companies keep just what they need for short-term production and new parts are shipped quickly when needed (just-in-time delivery)

3.5.4. most multinational corporations have moved the labor-intensive manufacturing, particularly assembly activities, to peripheral countries where labor is cheap, regulations are few, and tax rates are low

3.5.5. the manufacturing that remains in the core is usually high mechanized

3.5.6. technologically sophisticated manufacturing also tends to be sited in the core because both the expertise and the infrastructure are there

3.5.7. China and other lower wage countries are major recipients of industrial work that is outsourced or moved offshore

3.5.8. each steps in commodity production that used to take place within the confines of a single factory is now often oustsourced to suppliers, which focus their production and offer cost savings

3.5.9. when outsourced work is located outside of the country, it is said that it takes place offshore

3.5.10. consumption is still concentrated in the core

3.6. Made in America or Designed in America

3.6.1. the components of an iPod are produced by companies in Japan, Korea, Taiwan, and China

3.7. Major Influences on the Contemporary Geography of Manufacturing

3.7.1. industrial location is not just influenced by wage rates

3.7.2. the other key variables include transportation costs and options, regulatory constraints, expertise, and access to energy

3.7.3. Transportation

3.7.3.1. intermodal connections, places where two or more modes of transportation meet in order to ease the flow of goods and reduce the costs of transportation

3.7.3.2. Jacques Charlier has studied the major changes to the Benelux (Belgium, the Netherlands, and Luxembourg) seaport system and the role of containerization played in these changes

3.7.3.3. Charlier stressed the importance of containerization to the growth of sea trade in the Benelux ports

3.7.4. Regulatory Circumstances

3.7.4.1. regional trade organizations such as NAFTA and EU have trade agreements that influence where imported goods are produced

3.7.4.2. World Trade Organization (WTO) works to negotiate rules of trade among the member states

3.7.5. Energy

3.7.5.1. a huge system of pipelines and tankers delivers oil and natural gas

3.7.5.2. US consumption of petroleum and natural gas today is about 20 percent of the annual world total

3.8. New Centers of Industrial Activity

3.8.1. deindustrialization is a process by which companies move industrial jobs to other regions, leaving the newly deindustrialized region to work through a period of high unemployment

3.8.2. Taiwan to Guangdong, South Korea to Singapore, the islands, countries, provinces, and cities fronting the Pacific Ocean, are caught up in a frenzy of industrialization that has made the geographic term Pacific Rim synonymous with manufacturing

3.8.3. The Rise of East Asia

3.8.3.1. Four Tigers of East and Southeast Asia: South Korea, Taiwan, Hong Kong, and Singapore in the 1960s and 1970s

3.8.3.2. benefiting from the shift of labor-intensive industries to areas with lower costs

3.8.3.3. break-of-bulk point is where goods are transferred from one mode of transport to another

3.8.3.4. entrepot is a transshipment point

3.8.4. The Chinese Juggernaut

3.8.4.1. China's major industrial expansion occurred during the communist period

3.8.4.2. the Northeast district became China's industrial heartland

3.8.4.3. second largest industrial region in China, the Shanghai and the Chang Jiang District

3.8.4.4. China's large labor force has attracted hundreds of international companies

3.8.4.5. in addition to the enormous labor force, wages are comparatively low

3.8.4.6. in Chinese cities includiing Dalian, Shanghai, Shuhai, Ziamen, and Shenzhen, pollution-belching smokestacks rise above the urban landscape

3.8.4.7. streets are jammed with traffic ranging from animal-drawn carts and overloaded bicycles to trucks and buses

3.8.4.8. modern skyscrapers now dominate the skyline of the cities

3.8.4.9. the Northeast has become China's "Rust Belt"

3.8.4.10. many of its state-run factories have been sold or closed, or are operating below capacity

3.8.4.11. unemployment is high

3.8.5. The Wider World

3.8.5.1. Brazil, Russia, India, China, and South Africa are increasingly grouped under the acronym BRICS because these are the countries that are evidence of a shift in global economic power away from the traditional economic core

3.8.5.2. India has no major oil reserves

3.8.5.3. the country has a great deal of hydroelectric potential and access to ample coal

3.8.5.4. with a large labor force, a growing middle class, and a location midway between Europe and the Pacific Rim, India's economic influence is clearly on the rise

4. HOW HAVE DEINDUSTRIALIZATION AND THE RISE OF SERVICE INDUSTRIES ALTERED THE ECONOMIC GEOGRAPHY OF PRODUCTION?

4.1. service industries (tertiary industries) do not generate an actual, tangible product, instead, they encompass the range of services that are found in modern societies

4.2. quaternary industries for the collection, processing, and manipulation of information and capital )finance, administration, insurance legal services, computer services) and quinary industries for activities that facilitate complex decision making and the advancement of human capacities (scientific research, higher education, high-level management

4.3. Geographical Dimensions of the Service Economy

4.3.1. Rust Belt - evoking the image of long-abandoned, rusted-out steel factories (in the northeastern US, around Great Lakes)

4.3.2. Sun Belt - southern region - both the population and economy of this region have grown over the last few decades

4.4. High-Technology Clusters

4.4.1. a high-technology corridor is an area designated by local or state government to benefit from lower taxes and high technology infrastructure, with the goal of providing high-technology jobs to the local population

4.4.1.1. ex: California's Silicon Valley

4.4.2. technopole - an area planned for high technology

4.5. Tourism Services

4.5.1. tourism is now the world's largest service sector industry

4.5.2. growing middle class = increases in average life expectancy