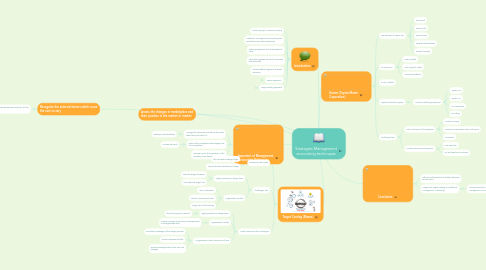

1. Recognise the external factors which cause the cost to vary

1.1. Make appropriate decision and plan for the changes

2. Assess the changes in marketplace and their position in the market or market

3. Important of Management Accounting Techniques

3.1. Manage the resources and reduce the costs rather than just control it

3.1.1. Develop cost leadership

3.2. Distinct the competitive advantages over the competitors

3.2.1. Increase its profit

3.3. Change or plan the operation of the company more flexible

4. Target Costing (Nissan)

4.1. Process of new model

4.1.1. The conceptual design stage

4.1.2. The production development stage

4.2. Challenges face

4.2.1. Highly pressure on design team

4.2.1.1. Need to design iterations

4.2.1.2. Not meet the target cost

4.2.2. Organisation conflict

4.2.2.1. Loss of discipline

4.2.2.2. Start to criticize each other

4.2.2.3. Large ratio of the savings

4.3. How to overcome the challenges

4.3.1. Highly pressure on design team

4.3.1.1. Stop the project or pause it

4.3.2. Organisation conflict

4.3.2.1. Project manager must have an interpersonal and negotiation skills

4.3.3. A organisation's team leader must have

4.3.3.1. Excellent knowledge of the design process

4.3.3.2. Good interpersonal skills

4.3.3.3. Good knowledge within time and cost budgets

5. Introduction

5.1. Assist manager in decision making

5.2. Traditional management accounting were quantitative and internally based

5.3. Rather prospective than the traditional ones.

5.4. Information gained from both internally and externally

5.5. Include different types of business scenarios

5.6. Kaizen approach.

5.6.1. Constant improvement over a long period of time

5.7. Target costing approach

5.7.1. Organisation plan market price in advance.

5.7.2. Ensuring profit will be made despite low sales.

6. Kaizen (Toyota Motor Coporation)

6.1. Key element of Kaizen (5S)

6.1.1. Seiri (Sort)

6.1.2. Seiton (Set)

6.1.3. Seiso (Shine)

6.1.4. Seiketsu (Standardize)

6.1.5. Seisuke (Sustain)

6.2. To reduce 3M

6.2.1. Muda (Waste)

6.2.2. Muri (Physical Stress)

6.2.3. Mura (Contradition)

6.3. 5 Why Method

6.4. Toyota Production System

6.4.1. Material Handling Equipment

6.4.1.1. Toyota SAS

6.4.1.2. Toyota AC²

6.4.1.3. BT Powerdrive

6.4.1.4. BT Tilting

6.5. Challenges face

6.5.1. Lack Involvement of employees

6.5.1.1. Provide Training

6.5.1.2. Provide Compensation plan and bonus

6.5.1.3. Promotion

6.5.2. Unclear structure and objective

6.5.2.1. Hire Expertise

6.5.2.2. Set an objective to achieve

7. Conclusion

7.1. Efficient and beneficial to today's business environment

7.2. Kaizen and Target Costing vs Traditional Management Accounting

7.2.1. Pros are more than Traditional Management Accounting