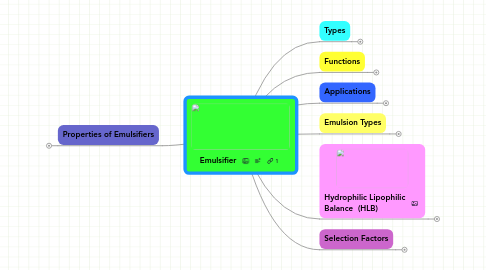

1. Properties of Emulsifiers

1.1. Mono- & Diglycerides

1.1.1. High lipophilic (HLB 1-10)

1.1.2. W/O emulsifier

1.1.2.1. Baked products

1.1.2.2. Peanut butter

1.1.2.3. Frozen desserts

1.2. Sucrose Esters

1.2.1. Mono- esters

1.2.1.1. HLB >16

1.2.1.2. O/W emulsions

1.2.2. Di-esters

1.2.2.1. HLB <10

1.2.2.2. W/O emulsions

1.2.3. Tri-esters

1.2.3.1. HLB ~1

1.2.3.2. Antifoaming agent

1.3. Sorbitan Monostearate (SPAN 60)

1.3.1. HLB 4.7

1.3.2. Used with polysorbates

1.4. Polysorbate 60

1.4.1. HLB 14.9

1.4.2. O/W emulsifier

1.4.2.1. toppings

1.4.2.2. cake icings

1.4.2.3. cake mixes

1.5. Polysorbate 65

1.5.1. O/W emulsifier

1.5.1.1. ice cream

1.5.1.2. ice milk

1.6. Polysorbate 80

1.6.1. HLB 15.0

1.6.2. O/W emulsifier

1.6.2.1. oils in special dietary foods

1.6.2.2. vitamin and mineral preparation

1.6.2.3. fat-soluble vitamins

1.7. Stearoyl Lactylates

1.7.1. High hydrophilic emulsifier

1.7.2. Application in baked products

1.8. Lecithin

1.8.1. Has wide range of HLB

1.8.2. Applications

1.8.2.1. baked goods

1.8.2.2. chocolate

1.8.2.3. instants food

2. Types

2.1. Nonionic

2.1.1. Uncharged particles

2.1.2. Insensitive to effects of pH and salt content

2.1.3. Example

2.1.3.1. Mono & Diglyceride

2.1.3.2. Sucrose Esters

2.1.3.3. Sorbitan monosterate

2.1.3.4. Polyoxyethylene glycol oleates

2.2. Anionic

2.2.1. -ve electrical charge

2.2.2. Influenced by pH and ionic strength

2.2.3. Example

2.2.3.1. Stearoyl lactylates

2.2.3.2. DATEM

2.2.3.3. Succinylated monoglycerides

2.3. Cationic

2.3.1. +ve electrical charge

2.3.2. Not used as food additive (Toxic)

2.4. Amphoteric

2.4.1. Possess both +ve & -ve charges

2.4.2. e.g. lecithin

3. Functions

3.1. Emulsification

3.1.1. All food products with Oil & Water

3.2. Emulsion stabilization

3.2.1. Frozen desserts

3.2.2. Salad dressings

3.2.3. Vegetable dairy products

3.3. Foaming

3.3.1. Toppings

3.3.2. Icings

3.3.3. Cakes

3.4. Defoaming

3.4.1. Syrups

3.4.2. Yeasts

3.5. Antistailing

3.5.1. Baked goods

3.6. Wetting

3.6.1. Spray-dried dessert mixes

3.6.2. Coffee whitener

3.6.3. Instant breakfast

3.7. Texture modification

3.7.1. Macaroni

3.7.2. Bread

3.7.3. Cakes

3.8. Crystal modification

3.8.1. Shortening

3.8.2. Coating

3.8.3. Peanut butter

3.9. Solubilizing

3.9.1. Colours

3.9.2. Flavors

3.9.3. Perfumes

4. Applications

4.1. Bread, rolls, Buns

4.1.1. Dough conditioner

4.1.1.1. Stearoyl lactylate

4.1.1.2. Polysorbate 60

4.1.2. Crumb softener

4.1.2.1. Mono- & diglycerides

4.1.2.2. DATEM

4.2. Cakes

4.2.1. Alpha- tending emulsifier

4.2.1.1. Acetic acid esters of monoglycerides

4.2.1.2. Lactic acid esters of monoglycerides

4.2.1.3. Propylene glycol esters

4.3. Confectionery products

4.3.1. Crystal modifier

4.3.1.1. Distilled monoglycerides

4.3.1.2. Lactic acid esters of monoglycerides

4.3.1.3. Sorbitan monostearate

4.3.1.4. Polysorbate 60

4.4. Frozen dairy Products

4.4.1. Lecithin

4.5. Noodles & Pasta

4.5.1. Fresh & Instant noodles

4.5.1.1. Increase water absorption by 1-2 %

4.5.1.2. Decrease cooking time

4.5.2. Macaroni & spaghetti

4.5.2.1. Provide a feeling of elasticity and smooth uniform surface which inhibit sticking after boiling.

5. Emulsion Types

5.1. W/O emulsion

5.1.1. HLB values 1- 10

5.1.1.1. Mono- & Diglycerides

5.1.1.2. Sucrose Esters

5.1.1.3. Sorbitan Monostearate

5.2. O/W emulsion

5.2.1. HLB values >10

5.2.1.1. Polysorbate 60

5.2.1.2. Polysorbate 65

5.2.1.3. Polysorbate 80

6. Hydrophilic Lipophilic Balance (HLB)

6.1. HLB 1-2

6.1.1. Antifoaming agents

6.1.1.1. Syrup

6.1.1.2. Yeast

6.2. HLB 3-6

6.2.1. W/O emulsifier

6.3. HLB 7-9

6.3.1. Wetting agent

6.3.1.1. Spray-dried dessert mixes

6.3.1.2. Coffee whiteners

6.3.1.3. Instant breakfasts

6.3.2. W/O or O/W emulsifier

6.4. HLB 10-18

6.4.1. O/W emulsifier