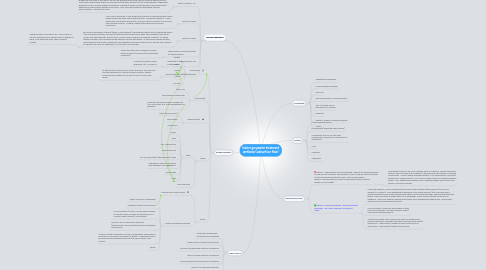

1. Design questions

1.1. Dimensions

1.1.1. Length

1.1.2. Width

1.1.3. Depth

1.1.4. Area

1.1.5. Volume

1.2. Loading rate

1.2.1. Areal HLR

1.2.2. Areal Organic loading rate

1.2.3. Volumetric hydraulic/organic loading rate (HRT for certain first-order degradation for example)

1.3. Feeding mode

1.3.1. Batch (flood & drain)

1.3.2. Intermittent

1.3.3. Continuous

1.4. Media

1.4.1. Type

1.4.1.1. Gravel

1.4.1.2. Sand

1.4.1.3. Soil, compost mix

1.4.1.4. Packing peanuts

1.4.1.5. Cut-up PET bottles/ special plastic media

1.4.1.6. Hydroponic media (e.g. Optiroc light expanded clay aggregate)

1.4.1.7. Wood chips

1.4.1.8. Peat

1.4.2. Size & porosity

1.5. Plants

1.5.1. Monoculture or polyculture

1.5.2. Genus and species selection

1.5.2.1. Ability to survive in greywater

1.5.2.2. Aesthetics (visual and olfactory)

1.5.2.3. Local availability (Hortico, Moore Water Gardens or Grand Moraine Growers on the advice of Dr Landman and Dr Zheng), local interest

1.5.2.4. Previous use in constructed wetlands (approximation of survival) and previous treatment performance

1.5.2.5. Tropical vs hardy temperate: survival in greenhouse temperatures in winter AND summer, go dormant in winter? Hopefully some of the plants will be growing during the first few months of the project.

1.5.2.6. Safety

2. Research questions

2.1. Effect of plants? No.

2.1.1. Has already been covered extensively in the literature (generally answer is plants have benefit, some studies say not much or no effect); results vary depending on many factors including choice of plant (multi-plant studies show significant differences between species); results of this question (significant difference in BOD removal between planted vs unplanted) would not reveal exactly how plants effect treatment or which plants had the most effect. Also, why would anyone install these systems without plants?? Results not useful.

2.2. Effect of depth

2.2.1. I am curious about this, could speak to the volume vs area debate and inform design. Keep area equal, same media (gravel? or packing peanuts?). Could dose equal volumes the whole time, do tracer tests to measure HRT of each, and compare removal. However, depth may be governed by space constraints.

2.3. Effect of media

2.3.1. We want an alternative to gravel (heavy, nonrenewable), and packing peanuts are an interesting option (low cost/waste material, low density) but performance has never been demonstrated (plant roots could break apart peanuts, surface area: volume could be reduced compared to gravel.) Compare identical designs, but one with packing peanuts and one with gravel. In this second design iteration, hold peanuts in place with a frame that can withstand both the buoyancy force and the load of plants and gravel (thin layer for aesthetics), can let plant roots through.

2.3.1.1. Depth question is important, BUT I don't want to risk two packing peanut designs when it might not work. First show they work, then do depth studies.

2.4. Which plants are recommended for these systems?

2.4.1. Plant polyculture and comment on which plants do well in (measured) environmental conditions)

2.5. What kind of effluent quality can be obtained?

2.5.1. Compare to health canada guidelines, etc.; can add UV

2.6. How should the systems be sized?

2.6.1. At two points in time, perform tracer studies to calculate HRT and drain wetlands to calculate porosity; kinetic: Sample across transect, attempt to fit BOD (COD?) to first order model

3. NEXT STEPS

3.1. Clarify two designs with calculations and drawings

3.2. Make decision and put into proposal

3.3. Finish lab methodology sections of proposal

3.4. Finish lit review sections of proposal

3.5. Finish composting toilet section of proposal

3.6. Write list of interview questions and proposed interviewees for proposal

4. Constraints

4.1. Aesthetically appealing

4.2. Locally available materials

4.3. Low cost

4.4. Low energy input, no chemical input

4.5. Size: Fit inside a small greenhouse or solarium

4.6. Flexibility

4.7. Ability to answer a research question

4.8. Safety

5. Criteria

5.1. Use of waste products

5.2. Functionality (expected performance)

5.3. Accessibility (use of off-the-shelf components, simplicity of construction & installation)

5.4. Cost

5.5. Flexibility

5.6. Aesthetics

6. DESIGN DECISION:

6.1. Option 1: improvement of first prototype. Support the packing peanuts so they do not compress; Add elbows to inlets to reduce short-circuiting; Control dosing with automatic valve; could include siphon design so final bucket fully drains (combination system, improve aeration of final stage.)

6.1.1. Uses waste products, low cost, relatively easy to construct, flexible (add more filters to the end of the train if needed), improvements should give acceptable functionality. Current design (bulkhead fittings 7 cm above bottom of barrels) makes tracer studies difficult, but modular design allows for sampling between barrels. NOT aesthetically pleasing, and an awkward shape and size for most spaces; not space-efficient.

6.2. Option 2: build long planters. Wood frame with pond liner. Not 100% sure how to construct outlet.

6.2.1. Uses new materials, could be expensive (pond liner with bulkhead fitting sealed in?) and more difficult to construct. More aesthetically appealing, more space-efficient (put along window or greenhouse wall); some people already have these in their houses/buildings, showing that they have appeal. This is the type of design they use in Earthships, so the research would be relevant to designers. Size is not flexible; flexibility would stem from changing the loading rate. Buried pipes would allow for sampling along transect.

6.2.2. Less innovative: "everyone" builds these as their pilot-scale wetlands. But the innovative aspect could be the packing peanuts.

6.2.3. This type of design often suffers from short circuiting due to media stratification creating preferential flow paths and density differences. Install baffles, design inlet and outlet zones to spread flow. High length to width ratio will help.