1. STRUCTURE

1.1. Internal sofa structure

1.1.1. Sub-parts characteristics

1.1.1.1. Plywood

1.1.1.1.1. It is mainly used as the main side plate of the inner frame of the sofa. The purpose is to support the whole sofa. It requires high pressure resistance, high alkali resistance, no rot, no broken marks, no bending and deformation

1.1.1.2. Square pillar

1.1.1.2.1. The main function is to connect the plywood to form a frame, which bears the burden of supporting the human’s weight. The material is required to have moderate hardness, strong to hold the nails, strong bending resistance and requires no rot, dead knot

1.1.1.3. Spring

1.1.1.3.1. (a) Horizontal S spring, which mainly bears the human’s weight, requires good elasticity, makes the sofa feel comfortable (b) Another called the sitting spring, and its shape looks like a pagoda, it mainly increases the longitudinal elasticity of the sofa to make it more comfortable to sit , and also prevents the sofa from being deformed in a short time

1.1.1.4. Elastic

1.1.1.4.1. (a) sitting elastic : harder, used in the seat, used more in some active cushion sofas (b) back elastic: softer, used on the back of the sofa to make the seat back comfortable

1.1.1.5. Foam

1.1.1.5.1. Due to the different parts of the sofa, the elasticity, hardness and density requirements of the foam are different. The sofa seat generally uses a high-density, high-rebound foam. The side foam requires softness and elasticity. The back and side parts use ordinary foam, which has lower elasticity and density

1.1.1.6. Spray cotton

1.1.1.6.1. It is mainly used on the surface of the foam to balance the smoothness of the surface and increase the comfort. It requires softness and good elasticity

1.1.1.7. Glue

1.1.1.7.1. Connect the foam. It requires good adhesive, low irritation, low toxicity and meets strict environmental protection requirements

1.2. Anatomy of a sofa

1.3. Sofa FOAM (In depth)

1.3.1. We use density to distinguish the foam; foam density is expressed in cubic meter. The higher density, the better quality it will be

1.3.2. The foam quality is also based on the rebound rate and compression set

1.3.3. Usually, a high-density foam is also high in hardness, but some high-density foams add super soft auxiliaries to make the foam super soft, so the foam hardness can vary when considering various foams densities

1.3.4. In average, the foam density for sofa cushions is about 32-40, and there are qualifications like: soft, hard, super soft and other specifications

1.3.5. According to the main standards, high density is above 45; medium density is between 18 and 45, and low density is under 18

1.3.6. In many countries, soft foam is more popular

1.3.7. Foam classification

1.3.7.1. Molded foam

1.3.7.1.1. made of polyamic acid material, mixed with various additives (foaming agent) / pressed into a simple mold to heat up to get shape / suitable for swivel chair cushions or back

1.3.7.2. Pack PE foam

1.3.7.2.1. molded from polyether foam, like foamed bread / can be foamed by mechanical equipment or with wooden wall / slicer is used to cut the thickness according to requirement / can be adjusted in hardness

1.3.7.3. Rubber foam

1.3.7.3.1. made of natural latex material / excellent elasticity / good resilience / no deformation / price is 3-4x pack PE foam

1.3.7.4. Bonded foam

1.3.7.4.1. very low cost / poor elasticity and low density

1.3.7.5. Price points

1.3.7.5.1. rubber foam > molded foam > pack PE foam

2. MANUFACTURING PROCESS

2.1. (1) Wood cutting

2.1.1. (2) Foam cutting

2.1.1.1. (3) Filling back & seat cushion

2.1.1.1.1. (4) Wooden frame quality control a. interface assembly should be tight, no opening, no abnormal noise b. frame structure is neat and tidy, with tight joints, and the surface has no obvious nails

2.1.1.2. (3b) fill inner bag with high-elastic cotton or duck feather with a filling machine

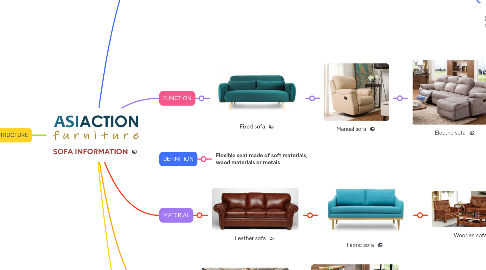

3. FUNCTION

3.1. Fixed sofa

3.1.1. Manual sofa

3.1.1.1. Electric sofa

4. DEFINITION

4.1. Flexible seat made of soft materials, wood materials or metals

5. MATERIAL

5.1. Leather sofa

5.1.1. Fabric sofa

5.1.1.1. Wooden sofa

5.1.1.1.1. Woven sofa

6. STYLE

6.1. European sofa

6.1.1. Chinese sofa

6.1.1.1. American sofa

6.1.1.1.1. Classical sofa

7. PLACES of USE

7.1. Home sofa

7.1.1. Office sofa

7.1.1.1. Public sofa