1. Project Team

1.1. Project Manager

1.2. Contract Management

1.3. Project Engineer

1.3.1. Installation teams, on-site

1.4. PRO

1.5. Finance

1.6. Project Coordinators

1.7. Project planning/scheduling

1.8. Document Control

1.9. Quality and HSE

1.10. Accounting

1.11. Logistics

1.12. Experts

2. Mandatory Personnel

2.1. Contractor

2.1.1. Project Mager

2.1.2. System Engineer

2.2. VTMS manufacturer

2.2.1. Project Mager

2.2.2. System Engineer

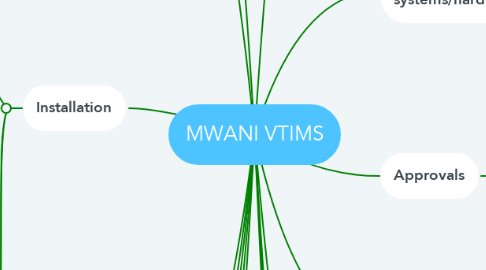

3. Installation

3.1. Scope of works

3.1.1. Lifting equipment e.g. crane for radar

3.1.2. Works on heights

3.1.3. Indoor works

3.1.4. Calibration

3.1.4.1. Meteo stations

3.1.4.2. Boat for calibration

3.1.4.2.1. CCTV

3.1.4.2.2. Radar

3.1.4.2.3. VHF

3.1.5. Configuration

3.1.5.1. Hardware

3.1.5.1.1. Radar

3.1.5.1.2. CCTV

3.1.5.1.3. AIS Base Station

3.1.5.1.4. VHF

3.1.5.2. Software

3.1.5.2.1. VTS

3.1.5.2.2. MIS (VTS DB)

3.1.5.2.3. Migration of data from existing system

3.1.5.3. Data Network

3.1.5.3.1. Data links between sites and HQ

3.1.5.3.2. Routers, firewalls, LAN Switches

3.1.5.3.3. External interface

3.1.6. Disposal of obsolete equipment

3.2. Metal structures for equipment fixing

3.3. Cables, surge protectors, connectors, jumpers

4. Acceptance

4.1. FAT

4.1.1. System FAT

4.1.2. Equipment FATs

4.1.2.1. Radar

4.1.2.2. CCTV

4.2. SAT

4.2.1. On sites

4.2.2. HQ and whole system

4.3. Handover

4.4. Punch list

5. Logistics

5.1. To KSA

5.2. Inside KSA

5.3. Customs clearance

5.4. Insurance

5.5. Storage

5.5.1. Central

5.5.2. On sites

6. System Design and Documentation

6.1. Master-Plan

6.2. Tests procedures

6.2.1. FAT (equipment)

6.2.1.1. Radar

6.2.1.2. CCTV

6.2.2. System FAT

6.2.3. SAT on-sites

6.2.4. SAT, HQ and final

6.2.5. SAT after punch-list rectification

6.3. BoM

6.4. Functional Block Diagrams

6.5. Wiring Diagrams

6.6. Cable Schedules

6.7. Site Plans

6.8. Civil and installation works specifications, method statements

6.9. Data flow diagrams

6.10. Telecommunication plan

6.11. Configuration

6.11.1. IP adresses

6.11.2. TDMA plans

6.11.3. Software configuration

6.12. Knowledge Base

7. SLA

7.1. Periodic Maintenance

7.2. Corrective Maintenance

7.3. Vendors

7.4. Local contractors

8. Training

8.1. Operators, Supervisors, Managers

8.2. System Administrators

8.3. Engineers

8.3.1. Customer

8.3.2. System Integrator

8.4. Vendor trainings

8.4.1. Factory

8.4.2. On-site

8.5. Learning Management System

9. Vendors

9.1. Radar

9.1.1. Terma

9.1.2. GEM Electronics

9.2. CCTV

9.2.1. Infinity

9.3. VHF

9.3.1. Spectra Engineering

9.4. Generatos

9.5. MW Links

9.6. Mast 30m

9.6.1. Zamil Steel

9.7. AIS Base Station

9.7.1. Kongsberg

9.8. IT equipment

9.8.1. Servers

9.8.1.1. On-stes

9.8.1.1.1. Single

9.8.1.2. HQ

9.8.1.2.1. Cluster

9.8.2. Workstations

9.8.2.1. PCs

9.8.2.2. Monitors

9.8.2.3. VTS Keyboards

9.8.2.4. VHF console

9.8.2.4.1. Touch-screen PC

9.8.2.4.2. PTT desk microphone

9.8.2.4.3. Speakers

9.8.2.4.4. PTT foot switch

9.8.3. LAN Switches, routers, firewalls

9.8.4. KVM console, PDU, Rack

9.8.5. UPS

9.8.6. Large screens

9.9. VTMS software

9.9.1. Wartsila

9.9.2. Leonardo

10. Integration wiht existing systems/hardware

10.1. AIS

10.1.1. CNS

10.2. VHF

10.2.1. Spectra Enineering

10.2.2. Omnitronics

10.3. Meteo Stations

10.3.1. Vaisala

10.4. Data buys

10.4.1. Axys

10.5. Radio Direction Finders

10.5.1. Rhotheda RT800

10.6. Jizan and Farasan system

10.6.1. Leonardo

10.7. Data network arrangement

10.7.1. STC

11. Approvals

11.1. Works

11.2. CST approval for radio transmitting equipment (radars, VHF)

12. Risks

12.1. Equipment damage

12.1.1. During delivery

12.1.1.1. to FAT

12.1.1.2. to KSA

12.1.2. During installation

12.2. Non acceptance

12.2.1. Additional equipment

12.2.2. Additional software, functionalities, integration

12.3. Lack of vendors support

13. Implementation

13.1. System Design

13.2. Manufacturing

13.3. Pre-assembly, testing, pre-configuration

13.4. FAT

13.5. Delivery to KSA, customs clearance

13.6. Installation, calibration, configuration

13.7. SAT

13.7.1. On-site

13.7.2. HQ and overall system

13.8. Trainings

13.8.1. On-site

13.8.2. HQ