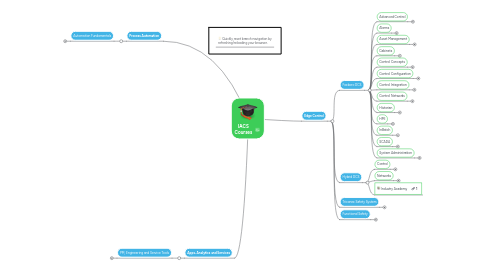

1. Process Automation

1.1. Automation Fundamentals

1.1.1. 1049 Introduction to Automation Systems

1.1.2. 1051 Understanding P&IDs and Control Strategies

1.1.3. 1052 Introduction to Schneider Electric Process Automation Solutions

1.1.4. 1076 Understanding the Basics of SCADA Systems for Process Control

1.1.5. 1079 Safety System Basics

1.1.6. 1132 Cabinet Engineering Basics

1.1.7. 1141 Processing Field Signals

1.1.8. 1159 Measuring Process Variables

1.1.9. 1160 Instrumentation for Measuring Process Variables

1.1.10. 1168 Control and Safety Hardware

1.1.11. 6211 Process Control Technology

2. :bulb: Quickly reset branch navigation by refreshing/reloading your browser.

3. Apps, Analytics and Services

3.1. PM, Engineering and Service Tools

3.1.1. Working Together: Flexible, Lean Project EXecution

3.1.2. Diagnostic and Maintenance Tools for Service Engineers

3.1.3. 1082 Foxboro Evo and Triconex Cybersecurity

3.1.4. 1112 Features and Functionalities of the Document Management System (DMS)

3.1.5. 1114 Your Secret Weapon: Industrial Cyber Security

3.1.6. 1121 RemoteWatch: Site Login, User Interface and Tools

3.1.7. 1122 Case Management System for Process Automation

3.1.8. 1178 FERRET Upload

3.1.9. 1179 EcoStruxure DCS Advisor Services: Features, Functionalities and Installation

3.1.10. 1180 Resource Management and Capacity Planning Tool

3.1.11. 1181 NetSight Console

3.1.12. 1182 Service Growth Synergies - Lever 5 Cross-Selling

3.1.13. 1185 Cybersecurity Delivery

3.1.14. 1186 Configuring Cybersecurity for Industrial Control and Safety Systems

3.1.15. 1222 Achieve Better Project Performance Using Knowledge Management Resources

3.1.16. 1225 NetSight Suite Console for Foxboro DCS Network Analysis

3.1.17. 1277 Monitoring System Health Using the Read the System Tool

3.1.18. 1291 Accurate SGV Inputs for Agile Business Decisions

3.1.19. 1294 Process Automation - Opportunity and Scope Change Management

3.1.20. 1295 Application of Project Management Principles Planning and Executing Projects

3.1.21. 1296 Process Automation - Risk and Contingency Management

3.1.22. 1297 Application of Project Management Principles Managing Clients

3.1.23. 1298 Application of Project Management Principles Practice and Review

3.1.24. 1310 Introduction to the Process Automation Project Manager SGV Birst Dashboards

3.1.25. 1383 Customer FIRST Program – Execution

3.1.26. 1384 Customer FIRST Program – Offer

3.1.27. 1388 Schneider Electric Cybersecurity Assessment

3.1.28. 1391 Cybersecurity Implementation in Endpoints

3.1.29. 1396 EcoFit Drives Services – Offer

3.1.30. 1398 Writing More Effective Technical Documents

3.1.31. 1399 Intellectual Property Patents

3.1.32. 1402 Customer FIRST Cybersecurity Add-On

3.1.33. 1408 Customer FIRST Program for Automation Control Systems

3.1.34. 1410 PA Cybersecurity Project Audits on Solutions Portal

3.1.35. 1416 Introduction to the EcoStruxure Vision Quality Control Solution

4. Edge Control

4.1. Foxboro DCS

4.1.1. Advanced Control

4.1.1.1. 5111 Configuring the PIDA Control Block

4.1.1.2. 5112 Configuring the FBTUNE Feedback Tuner Block

4.1.2. Alarms

4.1.2.1. 1071 Alarm Configuration Using IACC

4.1.2.2. 1072 Alarm Configuration Using FCS

4.1.2.3. 1136 Configuring Process Alarms

4.1.2.4. 1280 Working with the Alarm Shelving Utility

4.1.2.5. 1389 Alarm Management Systems from Design through Implementation and Maintenance

4.1.3. Asset Management

4.1.3.1. 1070 I/A Series System – Field Device Integration

4.1.3.2. 1097 Build and Manage a FOUNDATION Fieldbus System Using Field Device Manager

4.1.3.3. 1115 EcoStruxure Maintenance Advisor for Fieldbus Devices

4.1.3.4. 1118 Build and Manage a HART System Using Field Device Manager

4.1.3.5. 1158 Integrating Field Devices Using FDSI

4.1.3.6. 1272 Foxboro DCS: Build and Manage a HART System Using Field Device Expert

4.1.3.7. 1277 Monitoring System Health Using the Read the System Tool

4.1.3.8. 1325 Build and Manage a FOUNDATION Fieldbus System Using Field Device Expert

4.1.3.9. 2700 Foxboro Management Overview

4.1.3.10. 5010 System Advisor - Process Control

4.1.3.11. 5700 Control Software Management Overview

4.1.4. Cabinets

4.1.4.1. 1133 Cabinet Design

4.1.4.2. 1134 Cabinet Integration and Testing

4.1.4.3. 1226 Delivering Intelligent Enclosures for Industrial Control and Safety Installations

4.1.5. Control Concepts

4.1.5.1. 1053 Introduction to Foxboro DCS Architecture

4.1.5.2. 1054 Introduction to Foxboro DCS Architecture with Control Software

4.1.5.3. 1056 & 1061 Continuous Control Concepts Using IACC (Part 1 & 2)

4.1.5.4. 1057 & 1062 Continuous Control Concepts Using FCS (Part 1 & 2)

4.1.5.5. 1147 Understanding Foxboro System Architecture

4.1.5.6. 1151 Understanding the Basics of Control Configuration

4.1.5.7. 1152 Configuring Hardware Components

4.1.5.8. 1153 Configuring Control Objects

4.1.5.9. 1154 Deploying and Verifying Control Objects

4.1.5.10. 1155 Generating Bulk Data of Control Objects

4.1.5.11. 1157 Monitoring Control System Performance

4.1.5.12. 1176 Feedback and Cascade Control Solutions Using IACC

4.1.5.13. 1177 Feedback and Cascade Control Solutions Using FCS

4.1.5.14. Establishing and Maintaining Virtualized Control Systems

4.1.5.15. Advanced Configuration and Maintenance of Thin Clients

4.1.5.16. 2001v8 Foxboro Configuration Essentials

4.1.5.17. 2210v8 Foxboro System and Software Maintenance

4.1.5.18. 5001 Control Software Configuration Essentials (Blended Training)

4.1.5.19. 5001 Control Software Configuration Essentials (VILT)

4.1.5.20. 5001FV Control Software Configuration Essentials with FoxView

4.1.5.21. 5091 Foxboro SCP280

4.1.5.22. 5092 Foxboro SCP280 Tieback

4.1.5.23. 5210 Control Software and Foxboro System Maintenance

4.1.5.24. 5210FV Control Software and Foxboro System Maintenance with FoxView

4.1.5.25. 5691 Converting to Control Editors

4.1.5.26. 6235 Control Systems Engineering

4.1.6. Control Configuration

4.1.6.1. 1059 Foxboro Control Software Overview

4.1.6.2. 1060 FCS Configuration Tools

4.1.6.3. 1066 Control Loop Configuration Using IACC

4.1.6.4. 1067 Control Loop Configuration Using FCS

4.1.6.5. 1068 Configuring Sequence Controls Using IACC

4.1.6.6. 1069 Configuring Sequence Controls Using FCS

4.1.6.7. 1137 Configuring Discrete Control Loops

4.1.6.8. 1142 Configuring Ratio Control Loops

4.1.6.9. 1143 Configuring Complex Loops

4.1.6.10. 1148 Configuring Feedback Control Loops

4.1.6.11. 1149 Configuring Split-Range Control Loops

4.1.6.12. 1150 Configuring Cascade Control Loops

4.1.6.13. 1156 Configuring Sequence Controls

4.1.6.14. 1183 Discrete Control Solutions Using FCS

4.1.6.15. 1184 Discrete Control Solutions Using IACC

4.1.6.16. 1372 Industrial Automation Using EcoStruxure Automation Expert

4.1.6.17. 2101 Foxboro Continuous Control

4.1.6.18. 2102 Foxboro Sequence Control and Ladder Logic

4.1.6.19. 2612 I/A Configuration Component

4.1.6.20. 5101 Control Software Continuous Control

4.1.6.21. 5101FV Control Software Continuous Control with FoxView

4.1.6.22. 5102 Programmable Control Editor Tools

4.1.6.23. 5102FV Programmable Control Editor Tools with FoxView

4.1.6.24. 5612 Control Software Control Editor Tools

4.1.6.25. 5619 Foxboro SFC Conversion from HLBL

4.1.6.26. 5620 Foxboro DCS Control Editor Expert Tools

4.1.7. Control Integration

4.1.7.1. 1041 Effectively Integrating Control and Safety Systems

4.1.7.2. 1173 Controller Integration Using FDC280

4.1.7.3. 1395 Plant Optimization with Integrated Electrical Power and Process Automation Systems

4.1.7.4. 5223 Foxboro Field Device Manager with HART

4.1.7.5. 5653 Integrate FOUNDATION Fieldbus Devices with Control Editor

4.1.8. Control Networks

4.1.8.1. Configuring and Troubleshooting Foxboro Control Networks

4.1.8.2. 1120 Essential Practices for Advanced Control Network Management

4.1.9. Historian

4.1.9.1. 1074 AIM* – Designing and Building a Historian Database

4.1.9.2. 1075 Configuring Wonderware Historian (Foundation Edition)

4.1.9.3. 1144 Configuring Historian in a Foxboro System

4.1.9.4. 1145 Configuring Historian Client

4.1.9.5. 1146 Monitoring Historian and Managing Security

4.1.9.6. 2004 AIM*AT

4.1.9.7. 5004 Control Software Historian

4.1.10. HMI

4.1.10.1. 1063 FoxDraw – Designing and Building an HMI

4.1.10.2. 1064 Design and Build HMIs Using InFusion View (Control Edition) Tools

4.1.10.3. 1095 Configuring Better Displays Using Situational Awareness Graphics

4.1.10.4. 1098 Using ArchestrA Graphics to Implement High-Performance Control HMIs

4.1.10.5. 1227 Control HMI for Engineering Projects

4.1.10.6. 1326 Migrating FoxView Displays to Control HMI

4.1.10.7. 2015 Advanced FoxView Software

4.1.10.8. 5005 Control HMI

4.1.10.9. 5006 Control HMI Managed ArchestrA Graphics

4.1.10.10. 5300 Control HMI Process Operations

4.1.10.11. 5318 Control HMI for Operators

4.1.11. InBatch

4.1.11.1. 2625 Foxboro Batch Software

4.1.11.2. 5625 Foxboro InBatch

4.1.12. SCADA

4.1.12.1. 1108 Supervisory Control and Data Acquisition with Foxboro Evo SCADA

4.1.12.2. 1161 Data Acquisition, Communication, and Control Using SCD6000

4.1.13. System Administration

4.1.13.1. 1073 Introduction to System Manager

4.1.13.2. 1135 System Auditor for Foxboro Systems

4.1.13.3. 1166 Foxboro System Administration for Microsoft Windows 10 and Server 2016

4.1.13.4. 1170 Migrating Control Data after Installing Control Core Services and Control Software

4.1.13.5. 1172 Troubleshooting Foxboro DCS

4.1.13.6. 1179 EcoStruxure DCS Advisor Services: Features, Functionalities and Installation

4.1.13.7. 1224 Configuring Virtualization in Server 2016

4.1.13.8. 1228 Troubleshooting EcoStruxure System Advisor for Process Control

4.1.13.9. 1273 Optimize Plant Performance using Control Advisor

4.1.13.10. 1275 Executing Script-Based Installations Using PDQ Deploy

4.1.13.11. 1276 Security Enhancements in Control Core Services

4.1.13.12. 1278 Working with EcoStruxure System Advisor for Process Control

4.1.13.13. 1299 EcoStruxure DCS Advisor – Predictive Analytics

4.1.13.14. 1329 Monitoring Control Systems Using EcoStruxure DCS Advisor

4.1.13.15. 1334 EcoStruxure Augmented Operator Advisor for Control and Safety Systems

4.1.13.16. 2009 Advanced Foxboro System Administration

4.1.13.17. 2201v8 Foxboro Hardware Maintenance

4.1.13.18. 5012 Secured System Administration

4.1.13.19. 5014 Foxboro Managed Endpoint Protection

4.1.13.20. 5016 Foxboro DCS Security Administration Advanced

4.1.13.21. 5064 Control Software Historian Client Tools

4.1.13.22. 5090v9 Foxboro Virtualization Server

4.1.13.23. 5200FV Control Software Equipment Maintenance with FoxView

4.2. Hybrid DCS

4.2.1. Control

4.2.1.1. Building Systems in EcoStruxure Hybrid DCS

4.2.1.2. 1110 General Purpose Library for Unity Pro and Wonderware System Platform

4.2.1.3. 1127 Maximizing Productivity in Unity Pro

4.2.1.4. 1129 Common Safety: Integration of Control and Safety Systems

4.2.1.5. 1140 EcoStruxure Modicon Builder

4.2.1.6. 1339 Working with EcoStruxure Geo SCADA Expert ViewX

4.2.1.7. 1390 Maintenance and Troubleshooting of Modicon PACs Using Control Expert

4.2.1.8. 1394 EcoStruxure Automation Expert Configuration

4.2.1.9. 1405 EcoFit Drives Services – Execution

4.2.1.10. 1411 EcoStruxure Automation Expert: Architecture, Networking, Maintenance, and Diagnostics

4.2.1.11. 1412 Optimizing Industrial Solutions with Smart Equipment Platform

4.2.1.12. 9001 EcoStruxure Control Expert Configuration

4.2.1.13. 9101 EcoStruxure Hybrid DCS Essentials

4.2.1.14. 9102 EcoStruxure Hybrid DCS Configuration

4.2.2. Networks

4.2.2.1. 1163 Ethernet Networks

4.2.2.2. 1194 EcoStruxure Maintenance Advisor for OPC DA Assets

4.2.2.3. 9006 Introduction to Ethernet and TCP-IP

4.2.3. :books: Industrial Automation Academy

4.3. Triconex Safety System

4.3.1. 1041 Effectively Integrating Control and Safety Systems

4.3.2. 1080 Tricon System Installation

4.3.3. 1081 TriStation 1131 Application

4.3.4. 1082 Foxboro Evo and Triconex Cyber Security

4.3.5. 1119 TriStation 1131: Developing Advanced Safety Applications

4.3.6. 1175 Testing Safety Applications Using Triconex Safety Validator

4.3.7. 1192 Troubleshooting Triconex Safety Systems

4.3.8. 1203 Testing Safety Functionality Using Triconex Safety Validator TieBack

4.3.9. 1221 Tracking Changes to TriStation 1131 Project Files using System Advisor

4.3.10. 1223 Configuring and Monitoring Industrial Safety System Performance Using Process Safety Advisor On Premise

4.3.11. 1226 Delivering Intelligent Enclosures for Industrial Control and Safety Installations

4.3.12. 1271 Developing, Testing, and Deploying Safety Applications in TriStation 1131 Software

4.3.13. 1324 Dynamic Operational Risk Analyses Using PSA Cloud

4.3.14. 1330 Configuring Triconex Diagnostic Expert to Monitor Safety System Data

4.3.15. 1355 Monitoring Real-Time Safety and Risks Using Process Safety Advisor On Premise

4.3.16. 1403 Getting Started with Turbo-Machinery Control Applications

4.3.17. 8100 Cybersecurity for Triconex Systems

4.3.18. 8601 Triconex General Purpose (Tri-GP) Basic Maintenance

4.3.19. 8601A Triconex General Purpose (Tri-GP) Advanced Maintenance

4.3.20. 8602 Triconex General Purpose (Tri-GP) Configuration and Implementation

4.3.21. 8901 Tricon Basic Maintenance

4.3.22. 8901A Tricon System Advanced Maintenance

4.3.23. 8902 Tricon System and TriStation 1131 Configuration and Implementation

4.3.24. 8903 TriStation 1131 Standard Programming

4.3.25. 8903S Triconex Safety Considerations

4.3.26. 8905 Trident Basic Maintenance

4.3.27. 8906 Trident System and TriStation 1131 Configuration and Implementation

4.3.28. 8907 TriStation 1131 Programming with the HMI

4.3.29. 8921 Tricon CX Basic Maintenance

4.3.30. 8922 Tricon CX Configuration and Implementation

4.3.31. 8925A TriStation 1131 5.x: What’s New

4.3.32. 8925B Working with Triconex Diagnostic Expert

4.3.33. 8925C Tricon CX: What’s New

4.3.34. 8945 Triconex Safety Validator

4.3.35. 8948 Triconex Safety View

4.3.36. 8950 TriStation 1131 Advanced Programming

4.3.37. 8951 Creating Custom Function Blocks and Libraries

4.3.38. 8963 OPC and Networking Essentials

4.3.39. 8965 Triconex Trilogger Comprehensive

4.4. Functional Safety

4.4.1. 8801 Functional Safety Engineer (TÜV Rheinland) Certification Program

4.4.2. 8802 Functional Safety Technician (TÜV Rheinland) Certification Program

4.4.3. 8805 Functional Safety Engineer Process Hazard and Risk Analysis (TÜV Rheinland) Certification Program

4.4.4. 8811 Functional Safety for Burner Management Systems

4.4.5. 8821 Functional Safety for Managers