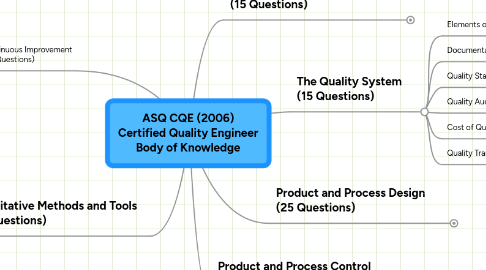

1. Continuous Improvement (30 Questions)

1.1. Quality Control Tools

1.2. Quality Management and Planning Tools

1.3. Continuous Improvement Techniques

1.4. Corrective Action

1.5. Preventive Action

2. Quantitative Methods and Tools (43 Questions)

2.1. Collecting and Summarizing Data

2.1.1. Types of Data

2.1.2. Measurement Scales

2.1.3. Data Collection Methods

2.1.4. Data Accuracy

2.1.5. Descriptive Statistics

2.1.6. Graphic Methods for Depicting Relatioships

2.1.7. Graphic Methods for Depicting Distributions

2.2. Quantitative Concepts

2.2.1. Terminology

2.2.2. Drawing Statistical Conclusions

2.2.3. Probability Terms and Concepts

2.3. Probability Distributions

2.3.1. Continuous Distributions

2.3.2. Discrete Distributions

2.4. Statistical Decision Making

2.4.1. Point Estimates and Confidence Intervals

2.4.2. Hypothesis Testing

2.4.3. Paired-Comparision Tests

2.4.4. Goodness-of-Fit Tests

2.4.5. Analysis of Variance (ANOVA)

2.4.6. Contingency Tables

2.5. Relationships between Variables

2.5.1. Linear Regression

2.5.2. Simple Linear Correlation

2.5.3. Time-Series Analysis

2.6. Statistical Process Control (SPC)

2.6.1. Objectives and Benefits

2.6.2. Common and Special Causes

2.6.3. Selection of Variables

2.6.4. Rational Subgrouping

2.6.5. Control Charts

2.6.6. Control Chart Analysis

2.6.7. PRE-Control Charts

2.6.8. Short-Run SPC

2.7. Process and Performance Capability

2.7.1. Process Capability Studies

2.7.2. Process Performance vs. Specification

2.7.3. Process Capability Indices

2.7.4. Process Performance Indices

2.8. Design and Analysis of Experiments

2.8.1. Terminology

2.8.2. Planning and Organizing Experiments

2.8.3. Design Principles

2.8.4. One-Factor Experiments

2.8.5. Full-Factorial Experiments

2.8.6. Two-Level Fractional Factorial Experiments

3. Management and Leadership (15 Questions)

3.1. Quality Philosophies and Foundations

3.2. The Quality Management System

3.2.1. Strategic Plannign

3.2.2. Deployment Techniques

3.2.3. Quality Information System (QIS)

3.3. ASQ Code of Ethics for Professional Conduct

3.4. Leadership Principles and Techniques

3.5. Facilitation Principles and Techniques

3.6. Communication Skills

3.7. Customer Relations

3.8. Supplier Management

3.9. Quality Improvement

4. The Quality System (15 Questions)

4.1. Elements of the Quality System

4.2. Documentation of the Quality System

4.3. Quality Standards and Other Guidelines

4.4. Quality Audits

4.4.1. Types of Audits

4.4.2. Roles and Responsibilities in Audits

4.4.3. Audit Planning and Implementation

4.4.4. Audit Reporting and Follow Up

4.5. Cost of Quality (COQ)

4.6. Quality Training

5. Product and Process Design (25 Questions)

5.1. Classification of Quality Characteristics

5.2. Design Inputs and Review

5.3. Technical Drawings and Specifications

5.4. Design Verification

5.5. Reliability and Maintainability

5.5.1. Predictive and Preventive Maintenance Tools

5.5.2. Reliability and Maintainability Indices

5.5.3. Bathtub Curve

5.5.4. Reliability/ Safety/ Hazzard Assesment Tools

6. Product and Process Control (32 Questions)

6.1. Tools

6.2. Material Control

6.2.1. Material Identification, Status, and Traceability

6.2.2. Material Segregation

6.2.3. Classification of Defects

6.2.4. Material Review Board (MRB)

6.3. Acceptance Sampleing

6.3.1. Sampling Concepts

6.3.2. Sampling Standards and Plans

6.3.3. Sample Integrity

6.4. Measurement and Test

6.4.1. Measurement Tools

6.4.2. Destructive and Nondestructive Tests