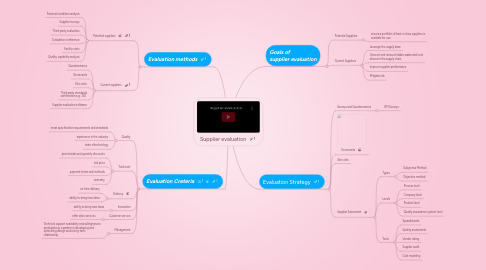

1. Goals of supplier evaluation

1.1. Potential Suppliers

1.1.1. ensure a portfolio of best in class suppliers is available for use

1.2. Current Suppliers

1.2.1. Leverage the supply base.

1.2.2. Uncover and remove hidden waste and cost drivers in the supply chain

1.2.3. Improve supplier performance

1.2.4. Mitigate risk

2. Evaluation Strategy

2.1. Surveys and Questionnaires

2.1.1. RFI Surveys

2.2. Scorecards

2.3. Site visits

2.4. Supplier Assesment

2.4.1. Types

2.4.1.1. Subjective Method

2.4.1.2. Objective method

2.4.2. Levels

2.4.2.1. Process level

2.4.2.2. Company level

2.4.2.3. Product level

2.4.2.4. Quality assuarance system level

2.4.3. Tools

2.4.3.1. Spreadsheets

2.4.3.2. Quality assesments

2.4.3.3. Vendor rating

2.4.3.4. Supplier audit

2.4.3.5. Cost modeling

3. Evaluation Creteria

3.1. Quality

3.1.1. meet specification requirements and standards

3.1.2. experience in the industry

3.1.3. state oftechnology

3.2. Total cost

3.2.1. price breaks and quantity discounts

3.2.2. bid price

3.2.3. payment terms and methods

3.2.4. warranty

3.3. Delivery

3.3.1. on time delivery

3.3.2. ability to bring new ideas

3.4. Innovation

3.4.1. ability to bring new ideas

3.5. Customer service

3.5.1. after sales services

3.6. Management

3.6.1. Technical support availability and willingness to participate as a partner in developing and optimizing design and a long-term relationship.

4. Evaluation methods

4.1. Potential suppliers

4.1.1. Financial condition analysis

4.1.2. Supplier surveys

4.1.3. Third-party evaluators

4.1.4. Evaluation conference

4.1.5. Facility visits

4.1.6. Quality capability analysis

4.2. Current suppliers

4.2.1. Questionnaires

4.2.2. Scorecards

4.2.3. Site visits

4.2.4. Third-party standards certification e.g.: ISO

4.2.5. Supplier evaluation software