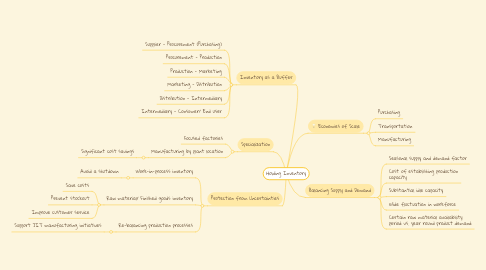

Holding Inventory

por An Quynh

1. Specialization

1.1. Focused factories

1.2. Manufacturing by plant location

1.2.1. Significant cost savings

2. Protection from Uncertainties

2.1. Work-in-process inventory

2.1.1. Avoid a shutdown

2.2. Raw material/ Finished goods inventory

2.2.1. Save costs

2.2.2. Prevent stockout

2.2.3. Improve customer service

2.3. Re-balancing production processes

2.3.1. Support JIT manufacturing initiatives

3. Inventory as a Buffer

3.1. Supplier - Procurement (Purchasing)

3.2. Procurement - Production

3.3. Production - Marketing

3.4. Marketing - Distribution

3.5. Distribution - Intermediary

3.6. Intermediary - Consumer/ End user

4. Economies of Scale

4.1. Purchasing

4.2. Transportation

4.3. Manufacturing

5. Balancing Supply and Demand

5.1. Seasonal supply and demand factor

5.2. Cost of establishing production capacity

5.3. Substantial idle capacity

5.4. Wide fluctuation in workforce

5.5. Certain raw material availability period vs. year round product demand