1. Gang milling

1.1. Uses more than 2 cutters

1.2. Used to mill a number of diff simultaneously

2. Straddle milling

2.1. Uses 2 Side and face cuters for machining 2 parallel surafes of the work piece

2.2. Cut same depth on workpiece

2.3. Reduces machining time

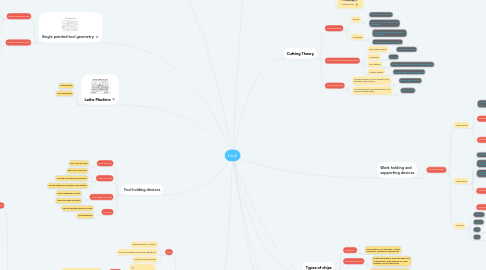

3. Lathe Machine

3.1. Cutting metal

3.2. Uses cutting tool

4. Turning Operations

4.1. Boring

4.1.1. To enlarge an existing hole

4.1.2. Must be done after drilling

4.2. Turning

4.2.1. Reduce diameter of work piece

4.2.2. Parallel to the axis of rotation

4.3. Threading

4.3.1. Parallel to axis of rotation

4.3.2. Faster

4.4. Facing

4.4.1. Fed on 1 end

4.4.2. Create a flat surface

4.5. Parting/Cut-off

4.5.1. Cut of a specific length of work piece

4.5.2. From center of work piece

4.6. Grooving

4.6.1. Fed near the mid

4.6.2. To a specific depth

4.7. Reaming

4.7.1. For finishing

4.7.2. Must be done after drilling

4.8. Drilling

4.8.1. Create a hole

4.8.2. In the middle

5. Single pointed tool geometry

5.1. Positive rake angle tools

5.1.1. Higher angle = Better surface finish

5.1.2. Less cutting force and power

5.1.3. Tool becomes weaker

5.1.4. Higher tool life

5.2. Negative rake angle tools

5.2.1. Surface finish sucks

5.2.2. Thin continuous chips

5.2.3. High cutting speeds

6. Tool holding devices

6.1. Front tool post

6.1.1. Only 1 tool at a time

6.2. 4-way tool post

6.2.1. hold up to 4 diff tools

6.2.2. Can find the centre of turning tool

6.2.3. Can be rotated and clamped in any position

6.3. Quick change tool post

6.3.1. Fast in swapping out tools

6.3.2. Useful for batch prodution

6.4. Tail Stock

6.4.1. Can be mounted with a drill chuck

6.4.2. Hold drilling bits

7. Milling machine

7.1. Intro

7.1.1. Either horizontal or vertical

7.1.2. Work is fed against a revolving cutting tool

7.1.3. Material removal process

7.2. 3 types

7.2.1. Horizontal

7.2.1.1. Advantage

7.2.1.1.1. Number of surfaces can be machined in 1 go due to large cutting tool area

7.2.1.2. Disadvatage

7.2.1.2.1. Cannot drill hole

7.2.2. Vertical

7.2.2.1. Used for profiling internal and external surfaces

7.2.2.2. Drilling and boring holes

7.2.2.3. Advantages

7.2.2.3.1. Can perorm mny types of machining processes than the horizontal machine

7.2.2.3.2. Easy to mount tools

7.2.2.4. Disadvantages

7.2.2.4.1. Obstructed view of cutter and workpiece

7.2.3. Universal

8. Milling cutters

8.1. Horizontal

8.1.1. Convex cutter

8.1.2. Slab mill

8.1.3. Slide and face staggered cutter

8.1.4. Angle cuter

8.1.5. Slitting saw

8.1.6. Slotting cutter

8.2. Vertical

8.2.1. Face mill

8.2.2. End mill

8.2.3. Ball-nosed slot drill

8.2.4. T-slot cutter

8.2.5. Fly cutter

8.2.6. Dovetail cutter

9. Ductile work material, low rake angle, low cutting speed, high depth of cut, high feedrate, poor use of cutting fluid

10. Supporting for long or thin workpiece

10.1. Centres

10.1.1. Dead/plain centre

10.1.1.1. Used for heavy loading turning

10.1.1.2. Apply grease = reduce friction

10.1.2. Live/revolving centre

10.1.2.1. Reduce temp generated at the centre

10.1.2.2. Can rotate along with the workpiece

10.2. Steadies

10.2.1. Travelling

10.2.1.1. Bolted to saddle

10.2.1.2. Useful when length of workpiece is machined

10.2.1.3. Prevents the metal from bending under cuttinf pressure

10.2.2. Fixed

10.2.2.1. Bolted to bed

10.2.2.2. Used to support work or long bar a distance from the chuck

10.2.2.3. Useful for turning a part of a long slender job

10.2.2.4. For drilling, boringo reaming at end of workpiece

11. Components

11.1. Table

11.1.1. With a leadscrew the table can move left and right

11.2. Spindle

11.2.1. Connected to the motor

11.2.2. Drives the arbor

11.3. Base

11.3.1. Foundation of machine

11.3.2. Storage tank for coolant

11.4. Brace

11.4.1. Additional support and rigidity to a long arbor

11.5. Arbor

11.5.1. Mount cutting tools

11.5.2. Rotates the cutter about a horizontal axis

11.6. Overarm

11.6.1. Support for free end of a long arbor

11.7. Column

11.7.1. Houses the electrical circuitry, the main drive and spindle bearings

11.8. Knee

11.8.1. Acts as a support for the saddle, work table and other accessories

11.9. Saddle

11.9.1. Enables the table to move along the clomun and provides vertical motion

12. Turning feeds and speeds

13. Cutting Theory

13.1. Cutting Methods

13.1.1. Oblique

13.1.1.1. Any angle other than 90

13.1.1.2. Better at leaving a finishing than orthogonal

13.1.2. Orthogonal

13.1.2.1. Set at 90 degrees to the direction of movement

13.1.2.2. Effectiveness depends on slope

13.2. Factors affecting cutting operations

13.2.1. Work piece material

13.2.1.1. Wood, Metal, Acrylic

13.2.2. Conditions

13.2.2.1. Wet/Dry

13.2.3. Tool material

13.2.3.1. Diamond, Cast cobalt alloys, Cemented carbide

13.2.4. Machine rigidity

13.2.4.1. Machine dsign/Machine condition

13.3. Cutting conditions

13.3.1. Increase feedrate, increase depth of cut, decrease cutting speed

13.3.1.1. Quick material remover

13.3.2. Decrease feedrate, decrease depth of cut, increase cutting speed

13.3.2.1. Finishing cuts

14. Types of chips

14.1. Affected by

14.1.1. Work Material, Tool Geometry, Cutting Conditions, Presence of cutting fluids

14.2. Discontinuous chips

14.2.1. Brittle work material, small rake angle, low cutting speed, large depth of cut, large feedrate, lack of cutting fluid

14.3. Continuous chips

14.3.1. Ductile work material, large rake angle, high cutting speed, small depth of cut, low feedrate, effiicient use of cutting fluid, cutting tool with less pressure

14.4. Continuous chips with a built-up edge

15. Work holding and supporting devices

15.1. Holding workpiece

15.1.1. 3 jaws chucks

15.1.1.1. Scrolling mechanism to clamp the work piece

15.1.1.2. Advantage

15.1.1.2.1. Workpiece will be clamped in the centre of the chuck

15.1.1.2.2. Can work with workpiece with large diameter but shorter length

15.1.1.3. Disadvantage

15.1.1.3.1. Low gripping strength

15.1.1.3.2. Jaws are not interchangeable

15.1.1.3.3. Clamping restriction

15.1.2. 4 jaw chucks

15.1.2.1. All jaws are operated independently

15.1.2.2. Need 4 chuck keys to complete clmaping of workpiece

15.1.2.3. More accurate as each jaw can be adjusted individually

15.1.2.4. Advantage

15.1.2.4.1. High gripping strength

15.1.2.4.2. Clamping variability

15.1.2.4.3. Can work with workpiece with larger diameter but shorter length

15.1.2.5. Disadvantage

15.1.2.5.1. Too long to set-up

15.1.3. Mandrels

15.1.3.1. Plain solid

15.1.3.1.1. Only 1 size of bore

15.1.3.2. Expnsion

15.1.3.2.1. Suitable for slight diff in diameter

15.1.3.3. Cone

15.1.3.3.1. Suitable for workpiece with diff hole diameter

15.1.3.4. Gang

15.1.3.4.1. Suitable for many identical workpieces

16. Gears and pulleys

16.1. Gears

16.1.1. Spur gears

16.1.2. Helical spur gears

16.1.3. Bevel gears

16.1.4. Helical gears

16.1.5. Worm and worm wheel

16.1.6. Rack and pinion

16.2. Pulleys and belts

16.2.1. Round belt

16.2.2. Flat belt

16.2.3. Vee belt

16.2.4. Timing belt

16.2.5. Conveyer belt