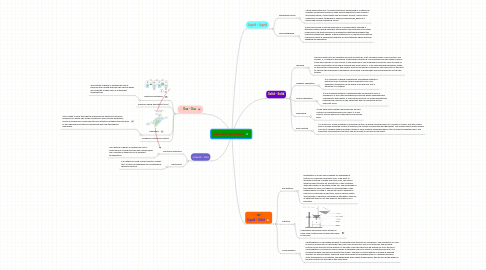

1. Gas - Gas

1.1. Fractional distillation

1.1.1. The mixture of gases is liquefied by use of pressure and cooling and then the various gases are collected as they boil off at different temperatures.

1.2. Pressure-Swing Adsorption (PSA)

1.3. Membrane

1.3.1. Gas is made to pass through the membrane by applying a pressure difference on either side of the membrane. This pressure difference causes a difference in dissolved gas concentration between the two faces of the membrane and hence a diffusional gas flow through the membrane.

1.4. Cryogenic Distillation Method

2. Liquid - Gas

2.1. Fractional distillation

2.1.1. The mixture of gases is liquefied by use of pressure and cooling and then the various gases are collected as they boil off at different temperatures.

2.2. Electrolysis

2.2.1. is a method of using a direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction.

3. Liquid - Liquid

3.1. Separating Funnel

3.1.1. Liquid-liquid extraction / solvent extraction/ partitioning is a method to separate compounds based on their relative densities in two different immiscible liquids, usually water and an organic solvent. Liquid-liquid extraction is a basic technique in chemical laboratories, where it is performed using a separating funnel.

3.2. Chromatography

3.2.1. It involves passing a mixture dissolved in a "mobile phase" through a stationary phase, which separates the analyte to be measured from other molecules in the mixture based on differential partitioning between the mobile and stationary phases. Subtle differences in a compound's partition coefficient result in differential retention on the stationary phase and thus changing the separation.

4. Liquid - Solid

4.1. Decantation

4.1.1. Decantation is a very quick method for separating a mixture of a liquid and a heavier solid. If we want to separate a mixture of water and same, First, we should allow the sand to settle on the bottom of the container. Then we poured off the water at the top. The advantage of this method is quick, but there is a disadvantage of this method which is rough. It cannot be used to separate a mixture of a liquid and a light sold, such as chalk in water. The particles of chalk are suspended in the water. They are so light that they do not sink down to the bottom for a long time.

4.2. Filtration

4.2.1. It separates immiscible liquids as well as liquid-solid mixtures.We use the filter paper in this case

4.3. Centrifugation

4.3.1. Centrifugation is used when we want to separate small amounts of suspension. The suspension of solid in liquid is poured into a centrifuge tube, then spin around very fast in a centrifuge. The spinning motion forces the solid to the bottom of the tube. Then the liquid can be poured off from the solid. Centrifugation is commonly used in dairies to separate milk from cream to make skimmed milk. It is possible because milk has less density than cream. The idea of centrifugation is applied in washing machine for drying clothes. There are many small holes in the washing drum in a washing machine. After the washing is completed, the washing will then rotate at high speed, this will forces the water on the wet clothes out through all the small holes.

5. Solid - Solid

5.1. Leaching

5.1.1. The solid mixture to be separated consists of particles, inert insoluble carrier A and solute B. The solvent, C, is added to the mixture to selectively dissolve B. The overflow from the stage is free of solids and consists of only solvent C and dissolved B. The underflow consists of slurry of liquid of similar composition in the liquid overflow and solid carrier A. In an ideal leaching equilibrium stage, all the solute is dissolved by the solvent; none of the carrier is dissolved. The mass ratio of the solid to liquid in the underflow is dependent on the type of equipment used and properties of the two phases.

5.2. Magnetic separation

5.2.1. It is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is attracted to a magnet.

5.3. Gravity separation

5.3.1. It is an industrial method of separating two components from a suspension or any other homogeneous mixture where separating the components with gravity is sufficiently practical. All of the gravitational methods are common in the sense that they all use gravity as the dominant force.

5.4. Winnowing

5.4.1. It is an agricultural method developed by ancient cultures for separating grain from chaff. It is also used to remove weevils or other pests from stored grain.

5.5. Zone melting

5.5.1. It is a group of similar methods of purifying crystals, in which a narrow region of a crystal is molten, and this molten zone is moved along the crystal (in practice, the crystal is pulled through the heater). The molten region melts impure solid at its forward edge and leaves a wake of purer material solidified behind it as it moves through the ingot. The impurities concentrate in the melt, and are moved to one end of the ingot.